Discover solutions for prototypes, jigs&fixtures, tooling and small series production

Smart comparison of lead time and cost reduction

In-house 3D printing vs outsourcing

Learn how to reduce

production costs

Take advantage of our

expert's advice

Profits

-

Return on investment <6 months

-

Tooling cost reduction more than 70% compared to outsourcing

-

Avoided production downtime in the even of supply chain disruptions or out-of-stock parts

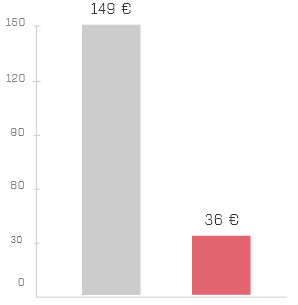

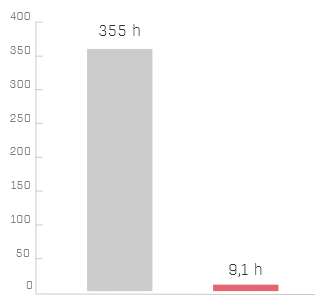

CAR SEAT FRAME ATTACHMENT

The steel frame of a car seat at certain stages of production must be restrained in a precisely known position to allow further assembly work. For this purpose, a jig consisting of several polyamide bolted components is used. The jigs are subject to rapid wear, and the use of metal assemblies has been ruled out due to the high cost of milling and the high risk of damaging the painted frame.

Production costs (EUR)

-

Outsourced Standard Technologies

-

In House 3D Printing

Lead Time (H)

-

Outsourced Standard Technologies

-

In House 3D Printing

Harness the power of

3D printing technology

in your industry

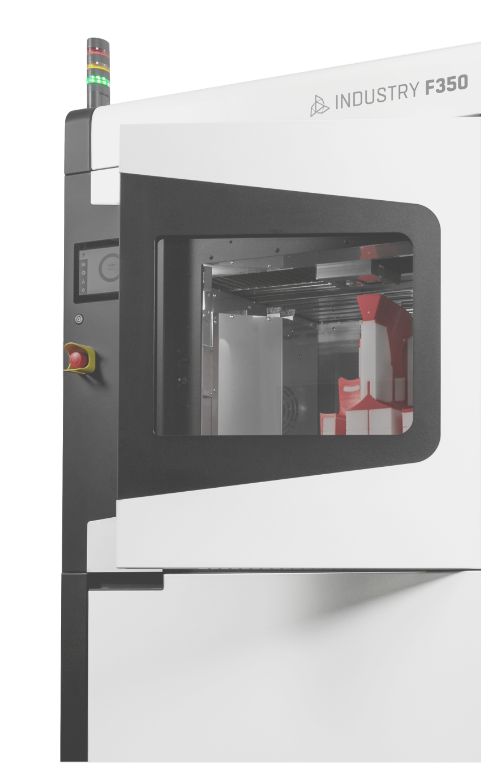

Industry F350 is a printer designed for professionals

SMART MATERIAL MANAGER

Built – in Smart Material System for material recognition.

VERSATILITY

The possibility of using three different modules in one 3D printer allows to produce repeatable models from the widest range of filaments.

COST-EFFICIENCY

Best in class total cost of ownership

PREHEATED MATERIAL

Materials are kept in a stable environment due to the heated materials chamber.

HEATED PRINTING CHAMBER

Heated build chamber ensures that the prints made of high-performance polymers like PC or PEEK are always of best possible quality.

SAFETY

Ensured user safety and work continuity proven by TUV Safety and Regular Production Surveillance.

ONLINE MONITORING

3DGence CLOUD includes such services and functionalities as running or queueing the prints, remote monitoring of the printer and prints status.

PRODUCTIVITY

The advanced kinematic system enables print speeds up to 400 mm/s and travel move of 1000 mm/s, all while ensuring top-standard results.