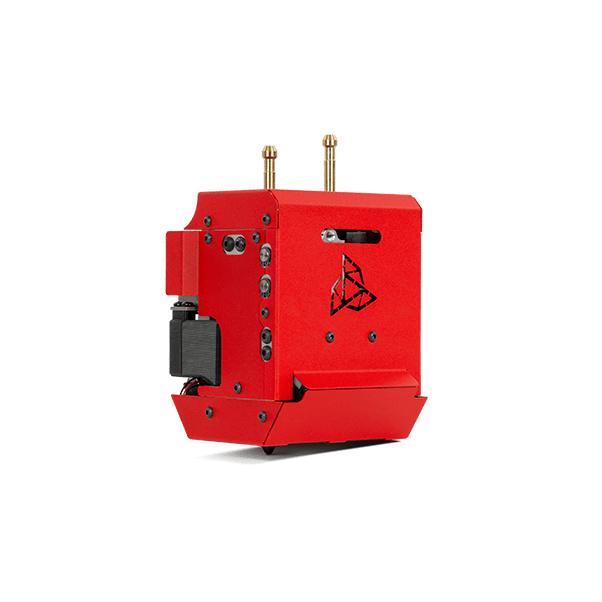

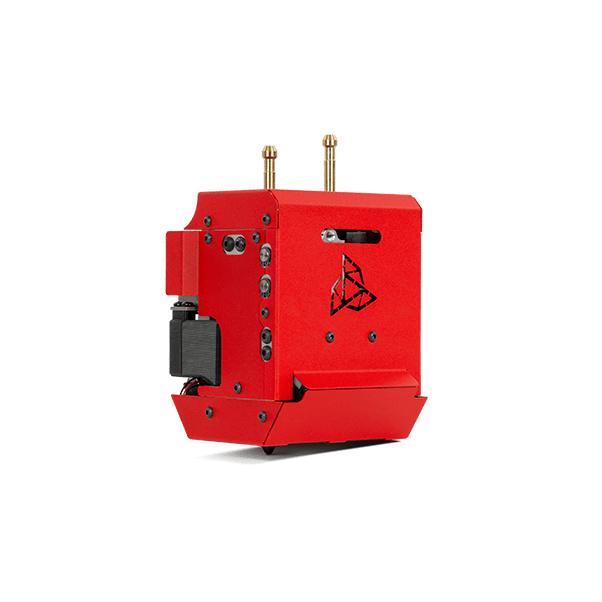

Le système modulaire utilisé dans 3DGence INDUSTRY F421 et INDUSTRY F350 est une solution pratique et économique. Le système modulaire 3DGence est unique dans le segment des imprimantes 3D industrielles. La possibilité d’utiliser quatre modules différents dans une imprimante 3D vous permet de produire des modèles reproductibles à partir de la plus large gamme de matériaux. Chaque module est adapté à un groupe spécifique de matériaux afin d’optimiser le processus d’impression. La mémoire interne des modules permet de gagner du temps et élimine le besoin de calibrage manuel. Tous les modules sont également équipés de deux têtes et d’un système de levage des buses inactives.

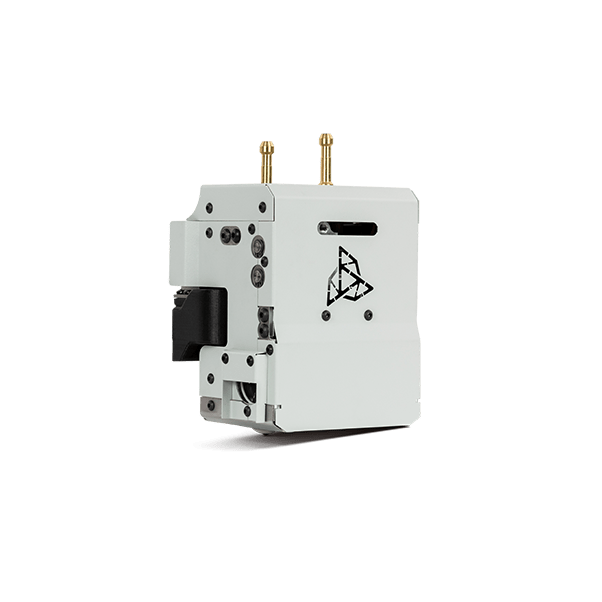

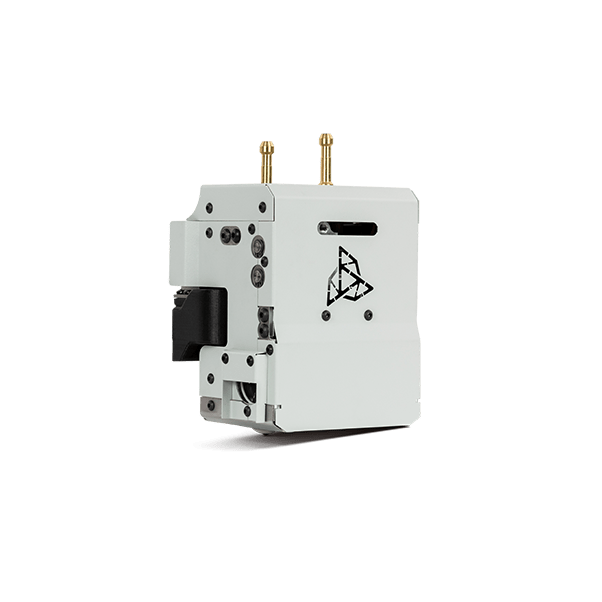

M280 est une unité d’impression de base dédiée à 3DGence INDUSTRY F421 et INDUSTRY F350, permettant d’imprimer votre matériel professionnel. Le M280 permet également d’imprimer des supports à partir de l’ESM-10 soluble.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

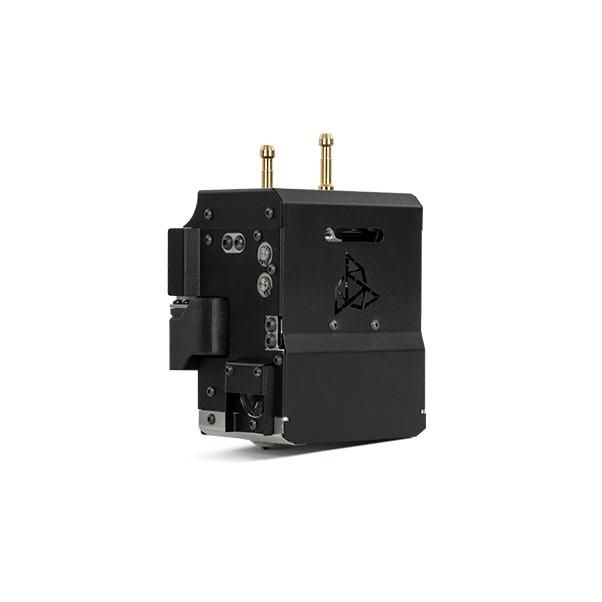

Le M360 est un module haute température qui permet à l’utilisateur INDUSTRY F421 d’imprimer les modèles d’ULTEM™, un polymère haute performance avec de très bonnes propriétés mécaniques, qui peut résister à des températures élevées. La M360 permet également d’imprimer à partir de matériaux d’ingénierie tels que le PC.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

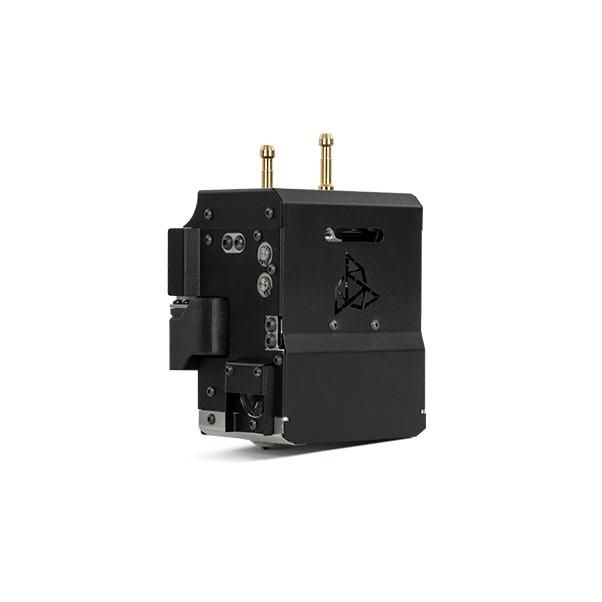

Le M500+ peut atteindre des températures jusqu’à 500°C.Cette température élevée, combinée à une chambre de travail chauffée, permet d’imprimer des polymères haute performance tels que le PEEK ou le PEKK sur l’INDUSTRY F421. Le M500+ peut imprimer les modèlesà partir dePEEK et PEKK en utilisant le matériau de support soluble, l’ESM-10 et l’ESM-30.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

À 280°C

À 360°C

À 500°C

0,5 / 0,5 mm

0,4 / 0,4 mm

0,4 / 0,4 mm

ABS, ABS Carbon, Addigy® F1030 CF10, ASA, PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS, PC-CF, PC-ESD, PEKK Carbon, ULTEM™ 9085

PEEK, PEEK AERO, PEEK-CF, PEKK-A, Victrex AM™200

ABS, ABS Carbon, Addigy® F1030 CF10, ASA, PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS FR, PC-ESD

PEEK, PEEK-CF,

Victrex AM™200

HIPS (cassable)

ESM-10 (soluble)

ESM-10 (soluble)

ESM-30 (soluble)

ESM-10 (soluble)

ESM-30 (soluble)

| Print Temperature | 340 – 500°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PEEK, PEKK |

| Support Materials | Dedicated breakaway ESM-10 (soluble) |

| Print Temperature | 265 – 340°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PC, PC-CF, PC-ABS, PC-ESD |

| Support Materials | Dedicated breakaway (ABS) |

| Print Temperature | 190 – 265°C |

|---|---|

| Nozzle Diameter | 0,6 / 0,6 mm |

| Model Materials | ABS, ASA, PP, PA-CF |

| Support Materials | HIPS (breakaway) ESM-10 (soluble) |

| Print Temperature | 190 - 265°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | ABS, PLA, PP, ASA, PA, TPU |

| Support Materials | BVOH (water soluble) HIPS (breakaway) ESM-10 (soluble) |