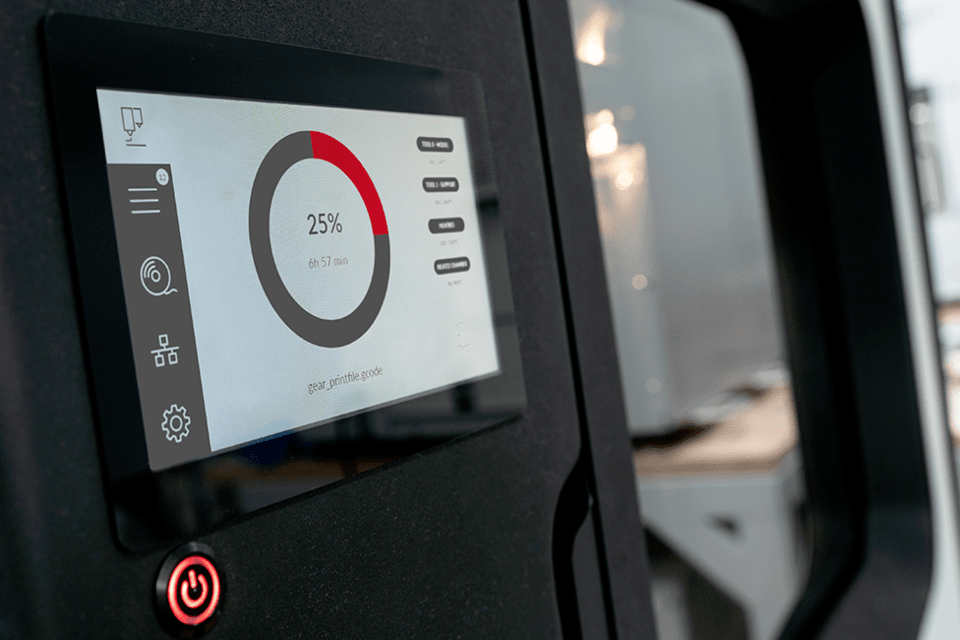

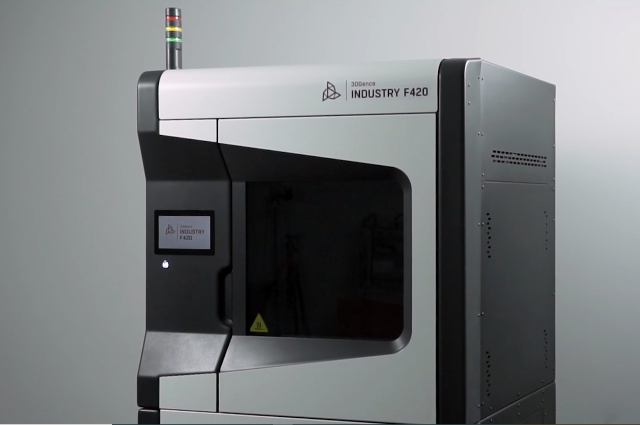

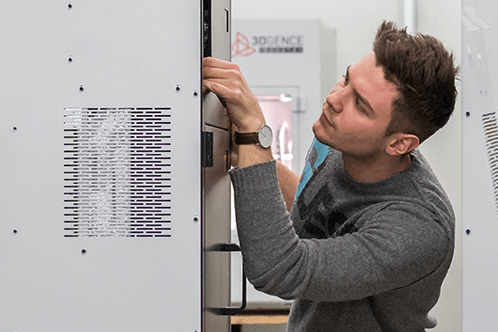

La 3DGence INDUSTRY F420 est une imprimante 3D industrielle conçue et construite pour imprimer à partir de matériaux à haute résistance tels qu’ULTEM™ ou PEEK. La plus haute qualité, une précision dimensionnelle et des résultats reproductibles à portée de main.

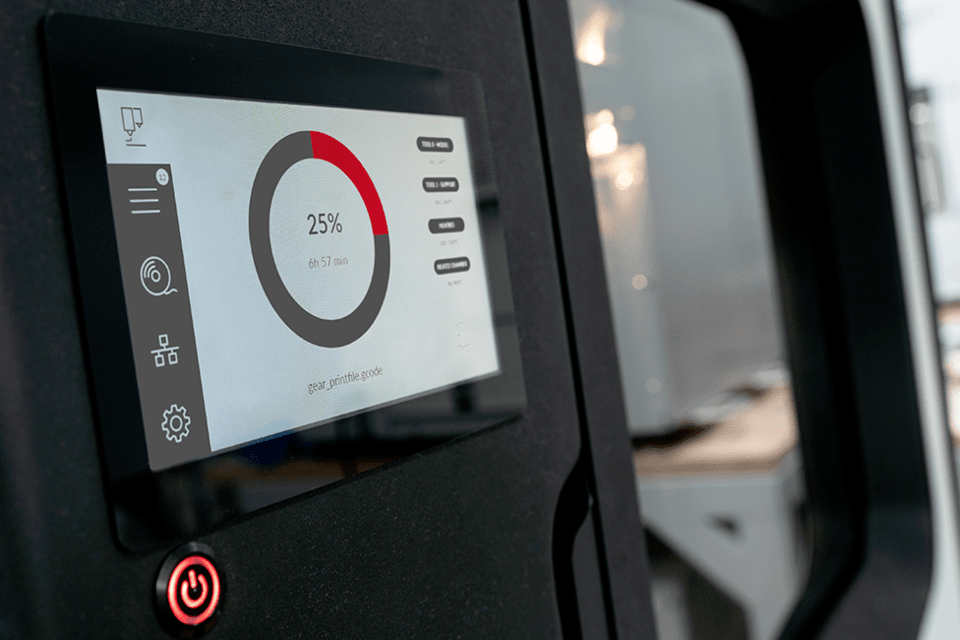

La 3DGence INDUSTRY F420 repousse les limites de la vitesse d’impression parmi les imprimantes 3D industrielles.

La vitesse d’impression est un paramètre clé du process. Une vitesse d’impression allant jusqu’à 400 mm/sec et une vitesse de réglage d’1 m/sec font de l’INDUSTRY F420 un outil de production très rapide. L’imprimante est un dispositif qui non seulement peut être utilisé pour le prototypage rapide mais aussi peut être un système de production avancé.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

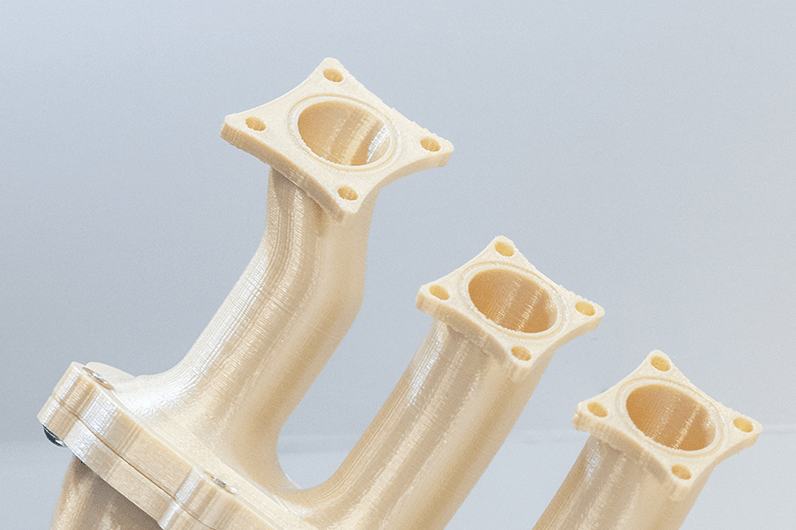

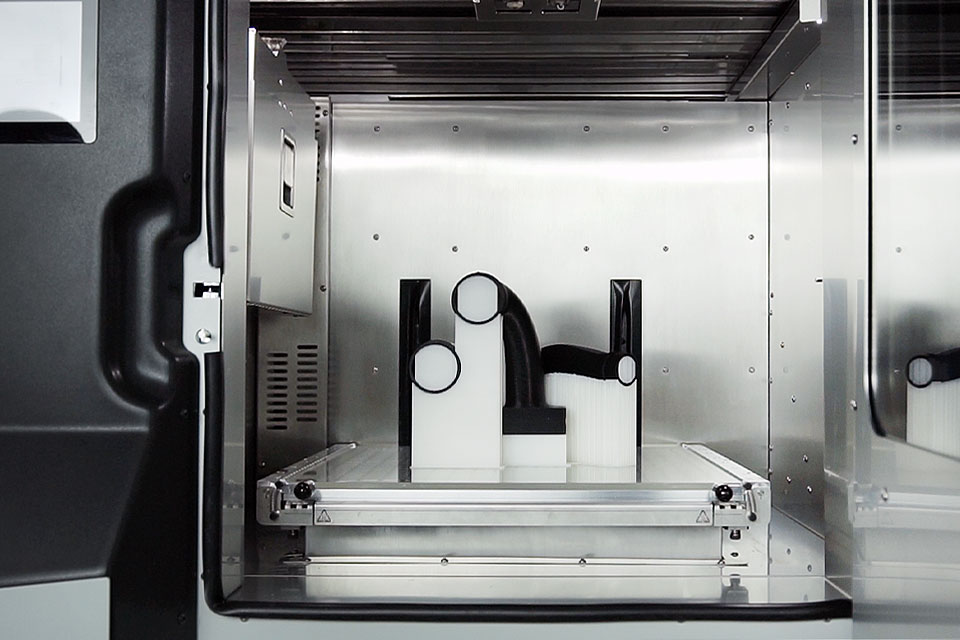

Le grand volume de la chambre de travail permet d’imprimer en une seule fois des modèles de grande taille ou des séries de production toutes entières.

Grâce aux dimensions de la chambre d’impression de 380 x 380 x 420 mm, vous pouvez imprimer même les grands modèles sans les diviser ou les fusionner ultérieurement. La 3DGence INDUSTRY F420 offre le meilleur rapport prix/volume de la chambre de travail de sa catégorie.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

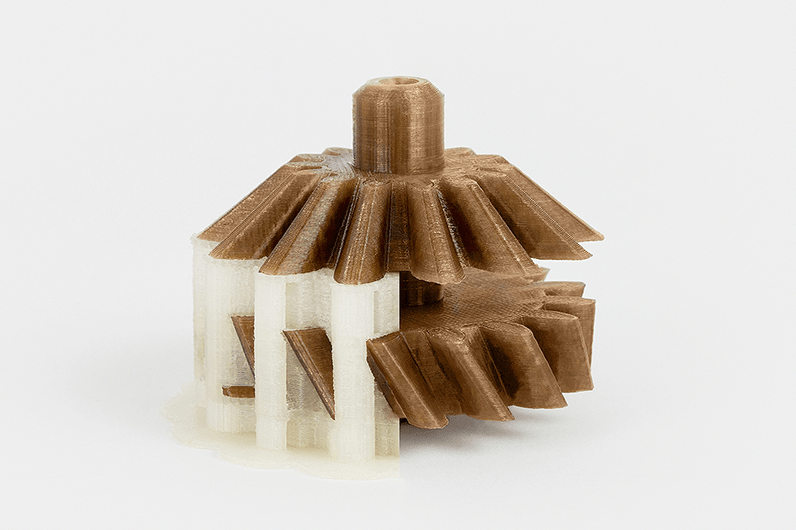

Imprimez à partir de matériaux de haute résistance et d’ingénierie qui peuvent être utilisés dans diverses industries.

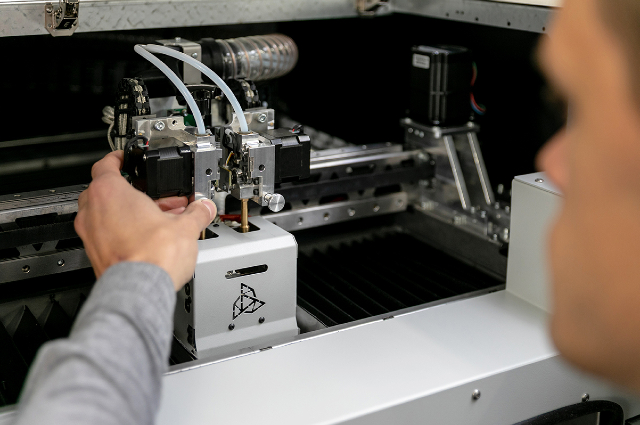

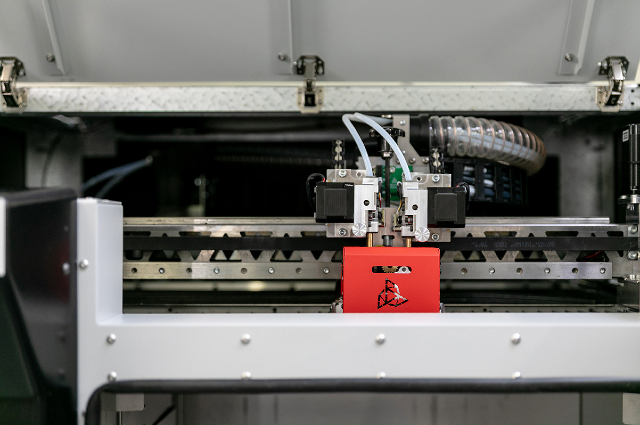

La 3DGence INDUSTRY F420 est équipée d’un système d’impression modulaire. Vous n’avez plus besoin d’utiliser plusieurs imprimantes 3D. Avec l’utilisation des modules d’impression en combinaison avec des profils de matériaux préparés, la qualité d’impression sera toujours au plus haut niveau.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

La chambre d’impression chauffée atteint une température élevée et la maintient constante.

Imprimez à partir de matériaux d’ingénierie et de haute résistance avec une excellente qualité, des propriétés mécaniques exceptionnelles et une grande précision dimensionnelle. Les matériaux ayant des propriétés de résistance élevées nécessitent des conditions de process d’impression stables et des températures d’extrusion élevées (aussi dans la chambre d’impression).

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

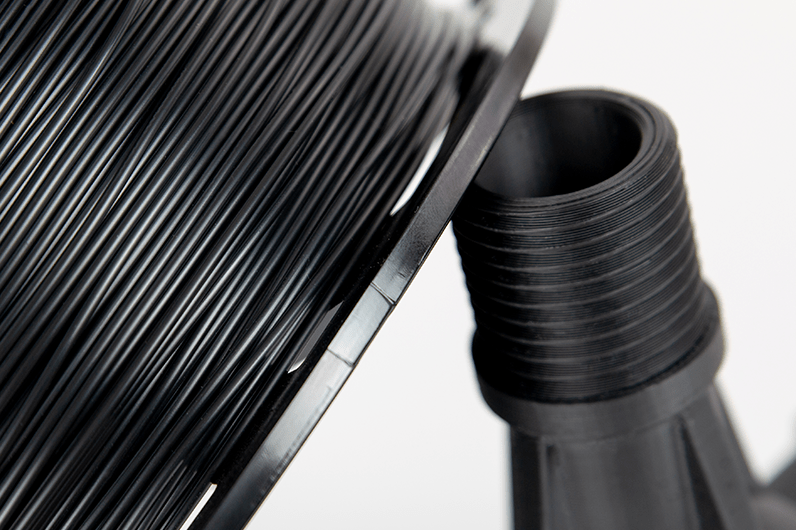

Gardez vos matériaux toujours secs et prêts à imprimer.

Les matériaux sont stockés dans des conditions stables grâce à la chambre des filaments chauffée. La chambre dispose de quatre emplacements pour les bobines : deux d’entre eux sont destinés au matériau modèle, les deux autres au matériau de support. Si l’une des bobines manque de matériau, celui-ci sera automatiquement remplacé dans l’extrudeuse par du matériau provenant d’une autre bobine du même type.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

Une garantie de conditions d’impression optimales.

Le lecteur NFC recueille des données sur la consommation du matériau pendant le process et sélectionne les conditions et la vitesse optimales du process. L’imprimante vérifie les informations sur le poids, le type, la couleur et la quantité de filament restant sur la bobine pour faciliter le process.

Smart Material Manager is a intelligent filament and printing environment control system.

SMM consists of a number of solutions:

Une solution qui ne nécessite pas d’entretien. Toujours prête à imprimer.

Les modules et l’imprimante sont calibrés automatiquement, ce qui garantit des pièces de haute qualité et une compatibilité dimensionnelle. L’imprimante ne nécessite pas de calibrage manuel.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

3D printing is increasingly used in medicine and allows for detailed planning of operations. This makes it possible to select the appropriate operating technique, discuss it in the team and shorten the time of the procedure itself.

The construction of a prototype form is a long-term process, and the implementation time is very important. Check what goals Geo Globe Polska achieved thanks to the 3D printing technology.

The use of 3DGence INDUSTRY F340 allowed verifying the vacuum manifold, which is one of the elements creating a hydraulic system of a pump compartment inside fire engines.

In the process of revitalization, it is important to present the building’s body with a high detail referring to the original design. PANOVA created the complex building model based on archival materials from 1897 in 1:75 scale using 3D printing technology.

Electric auto-revolution can be supported by 3D printing technology! Using 3D printer AGH Racing could test original design of steering knuckle at a very low cost and in just two days.

Le PEEK est un polymère à haute résistance de la famille des PAEK, qui offre une combinaison unique de propriétés.

ULTEM™ est un polymère de haute performance qui est largement utilisé dans les segments de marché les plus exigeants.

Le PEKK est un polymère de haute performance de la famille des PAEK, dont les applications sont très variées.

L’ASA est un polymère thermoplastique qui combine des propriétés mécaniques élevées, la résistance aux UV et la capacité à fonctionner dans des conditions de forte humidité.

Le PC est l’un des polymères techniques les plus durables, les plus durs et les plus résistants à la chaleur.

Un polymère à base de polystyrène similaire à l’ABS, leurs propriétés mécaniques et leur résistance globale sont très similaires.

Vous n’êtes pas convaincu que vous bénéficierez de l’impression en 3D?

Les spécialistes de 3DGence identifieront les domaines d’application possibles de l’impression 3D dans votre entreprise et montreront les économies qui peuvent être générées par l’utilisation de cette technologie à long terme.

L’audit technologique est un service gratuit.

Reliability and full functionality of the machines.

Elimination of production stoppages

in order to maintain processes continuity.

Original spare and wear parts and professional service.

Full support of 3DGence team in terms of machine maintenance and service.

Technologie d’impression

FFF

Espace de travail

380 x 380 x 420 mm (60 648 cm3)

Epaisseur minimale de la couche

50 µm

Nombre de têtes

2, système de nettoyage des têtes

Diamètre du filament

1,75 mm

Temp. de la tête (max.)

500°C

Temp. de la table (max.)

180°C

Température de la chambre d’impression (max.)

180°C (chauffage actif)

Filament chamber temperature

50°C

Mouvements de réglage

1000 mm/s

Vitesse d’impression

Jusqu’à 400 mm/s

Alimentation requise

230V

Consommation électrique (max.)

4600W

Consommation électrique (moyenne)

1500W

Communication

Ethernet, Wi-Fi, USB

Découpe de modèles

3DGence SLICER 4.0

Services cloud

3DGence CLOUD

Filtration

Unité de filtration avancée

Capteurs

Porte principale de la chambre, clapet supérieur, capteurs de température, interrupteur d’urgence

ASI

Oui, en option

Autres

Arrêt à distance de l’équipement