ABS

ABS filament is one of the most popular thermoplastics, regardless of production technology in 3D printing

ABS filament is one of the most popular thermoplastics, regardless of production technology in 3D printing

3DGence ABS can be printed with ESM-10, soluble support material. This combination allows printing complex geometries, functional prototypes and many more.

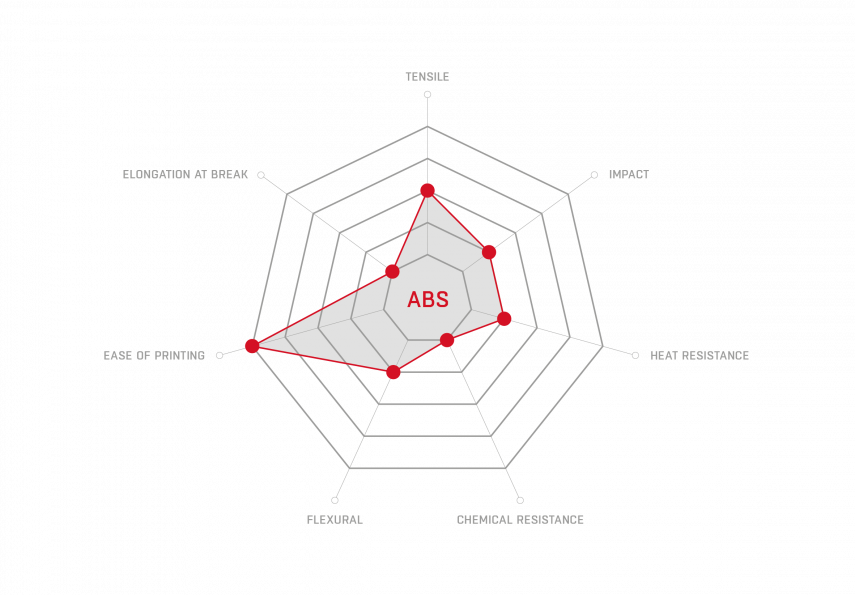

It is always easy to process and it has good mechanical properties to price ratio. ABS is a machinable material – it is possible to make the technological holes and even threads on the printed model. Relatively high hardness of the material results in high scratch resistance.

ABS filament shows some basic chemical resistance for acids, alkalis, and alcohols. It can be used in the applications that work in the temperature range of -20 – 80C. ABS is a recyclable material. The surface of the model made of ABS will be matte and the colours would be slightly less saturated than PLA made models.

ABS is not UV resistant, it should not be directly exposed to sunlight.

The use of an industrial 3D printer allows easily replacing the grinder's side handle in case of damage of the original.

3D printing is a quick method to get custom items. Tablet car mount was made with ABS, the same material as the dashboard, to maintain a similar design.

The prototype made with ULTEM™ was used for functional laboratory tests.

3D printing is a quick method to get custom items. 3DGence engineer made from reinforced material such as PA-CF a server casing.

In record time – only 5 days of printing, 3DGence engineers built a 120 kg robotic arm with great repeatability of movement. It has six degrees of freedom and can easily manipulate other objects.

The implementation of 3D printing inside the company has a number of benefits. With this technology, Balluff’s engineers can design completely new assembly elements, that are extension of a ready company solution.

We will help you to choose the right material