The most versatile industrial 3D printer capable of 3D printing with the widest range of engineering materials. Designed to produce high-quality and durable parts with complex geometry.

The industrial customers always expect the best. As the manufacturer 3DGence aims to provide the highest products quality, productivity improvement and the safety work environment. Reliability is a key: the models should be printed correctly every time. There are several features that characterize the real industrial 3D printer, e.g. it has to provide repeatability of the prints, consistent conditions during storage and printing process, ensure high dimensional accuracy or allow to print very complex geometries with either break-away or soluble support materials. Learn more about the features and unique qualities that position 3DGence INDUSTRY F340 among the most reliable and veratile industrial 3D printers in the world.

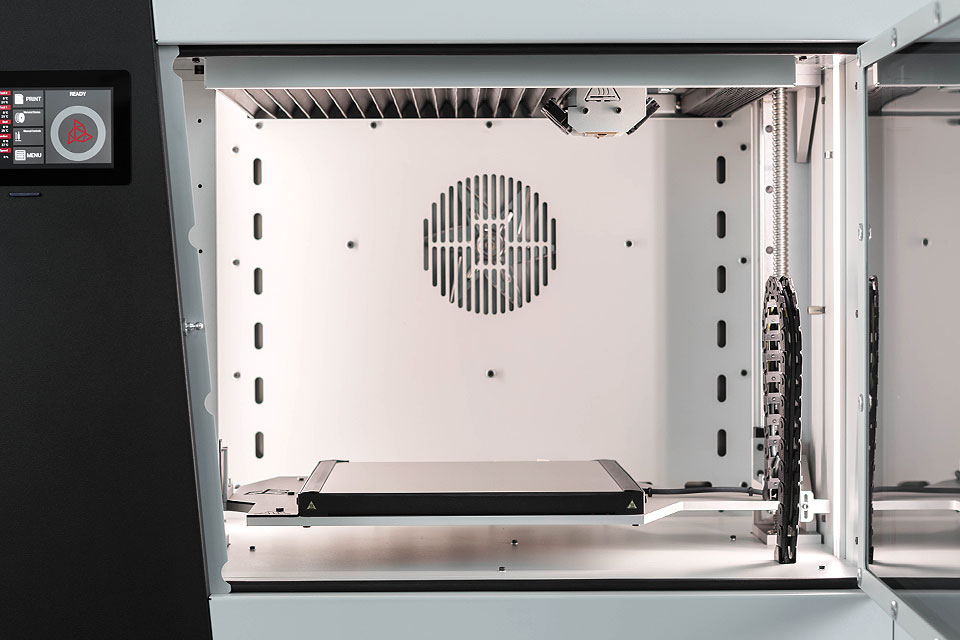

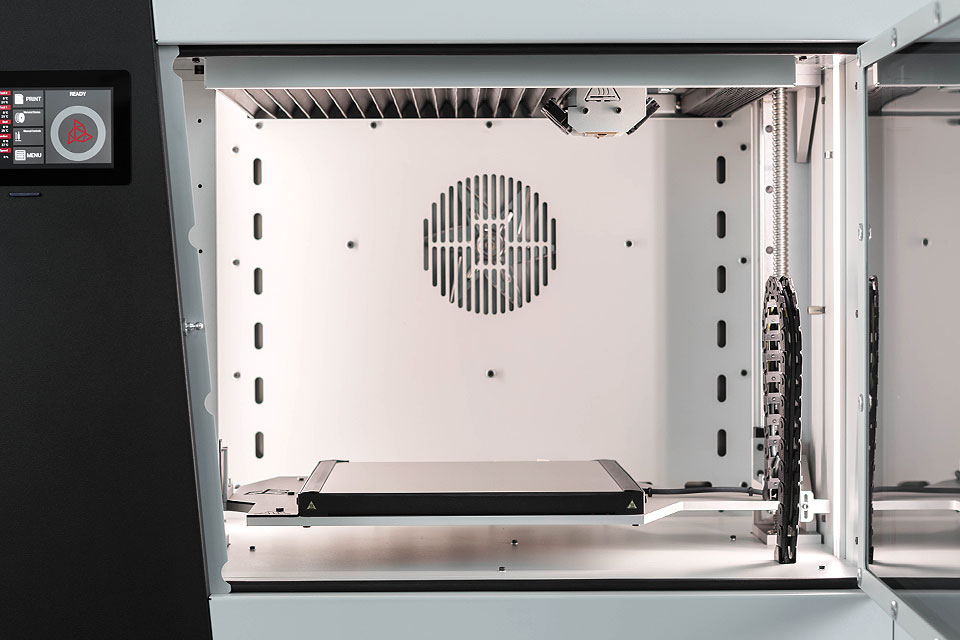

Best in class price to build volume ratio.

With the dimensions of 260 x 300 x 340 mm you can 3D print large models in one run. The total build volume of 26 520 cm^3 combined with very attractive end user price results in best-in-class price to volume ratio within the industrial grade 3D printers.

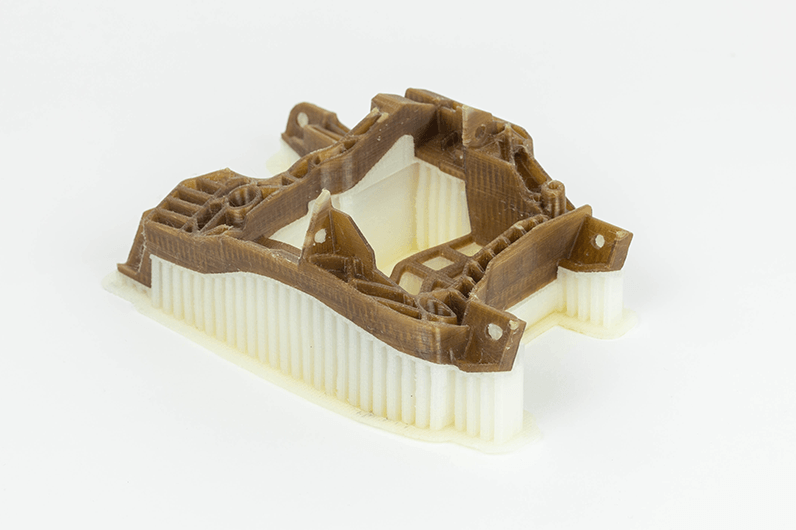

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

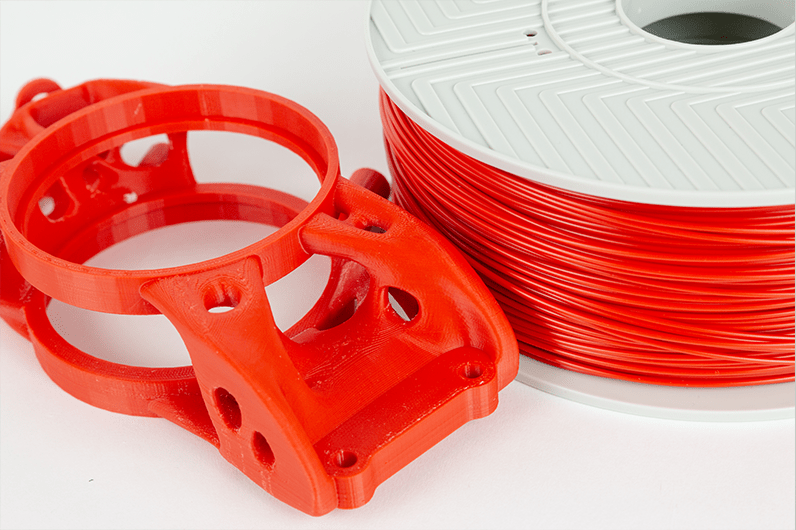

Wide range of engineering materials that can be processed at very high temperatures up to 500°C.

3D print from multiple filaments, from PLA to PEEK on a single machine, all you need to do is replace the printing module.

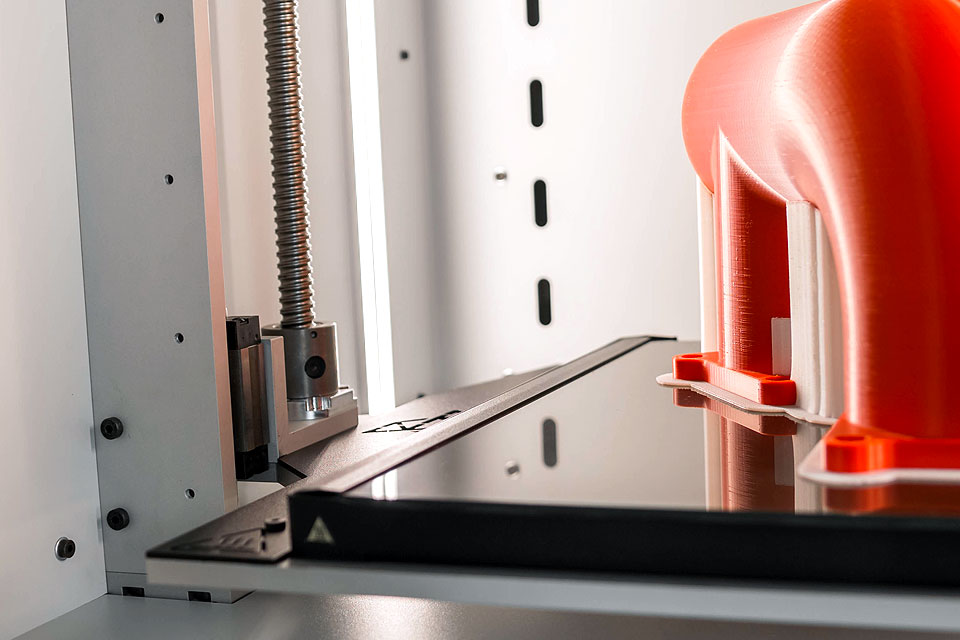

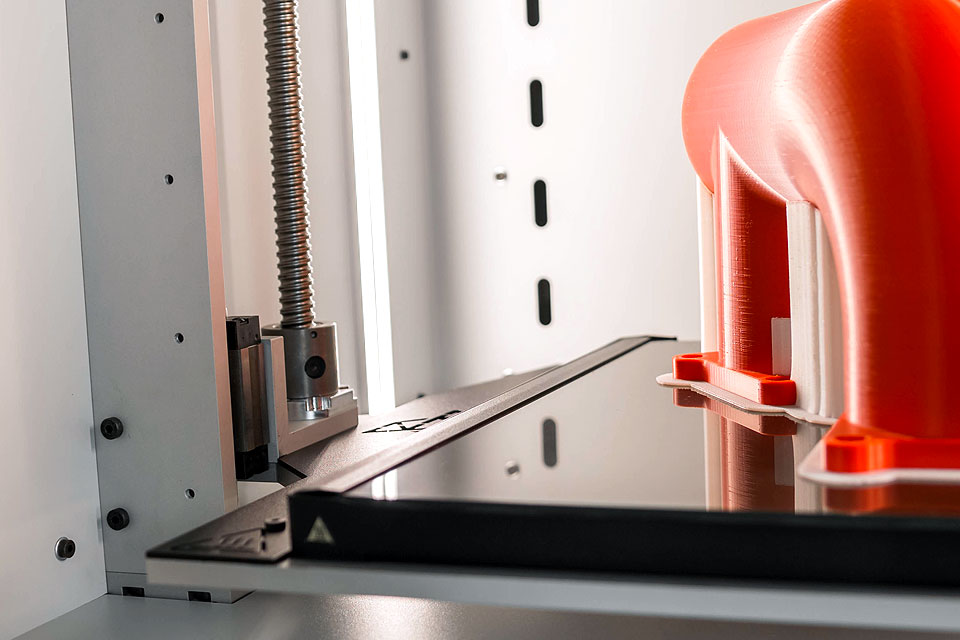

Dimensional accuracy of the models and their high quality.

The actively heated chamber can reach temperature up to 85°C and it makes 3D printing with ABS, PEEK, PEKK and other engineering polymers an easy task.

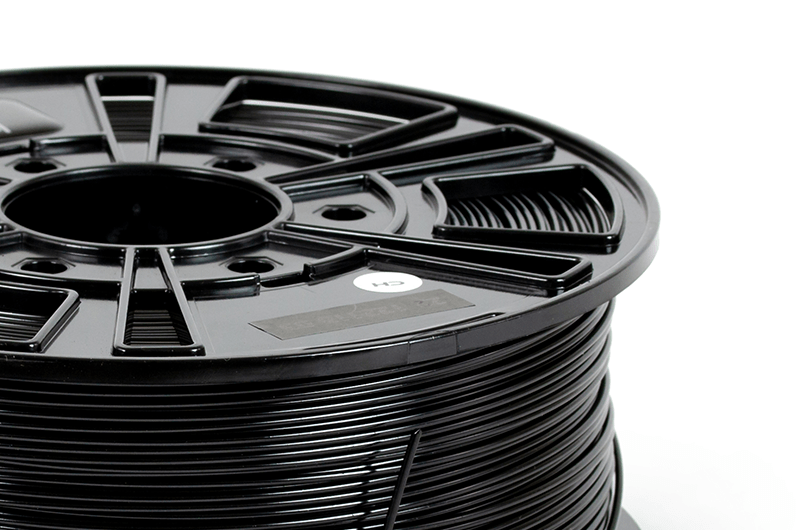

Controlled humidity for loaded materials.

The materials are always pre-warmed and dry. Most of the high-performance polymers have to be dried before use.

Humidity for the loaded materials will be reduced regardless of the 3D printers operational status thanks to the active chamber heating system

The material control system indicating the weight of the loaded material on each of the reels measures its accuracy up to 5 grams. The data is compared with the information about the required amount of filament needed to complete the printing process.

In the case of undersupplying, the system informs the user about the lack of the material before the start of the printing process.

The flow control system located in the extruders is designed to maintain constant control of print precision during the process.

When the margin of error is exceeded, 3DGence INDUSTRY F340 will automatically stop printing.

Low maintenance solution.

Tensometric system used in 3DGence INDUSTRY F340 allows to automatically calibrate this 3D printer.

Humidity for the loaded materials will be reduced regardless of the 3D printers operational status thanks to the active chamber heating system

The material control system indicating the weight of the loaded material on each of the reels measures its accuracy up to 5 grams. The data is compared with the information about the required amount of filament needed to complete the printing process.

In the case of undersupplying, the system informs the user about the lack of the material before the start of the printing process.

The flow control system located in the extruders is designed to maintain constant control of print precision during the process.

When the margin of error is exceeded, 3DGence INDUSTRY F340 will automatically stop printing.

Guarantee of optimal working conditions.

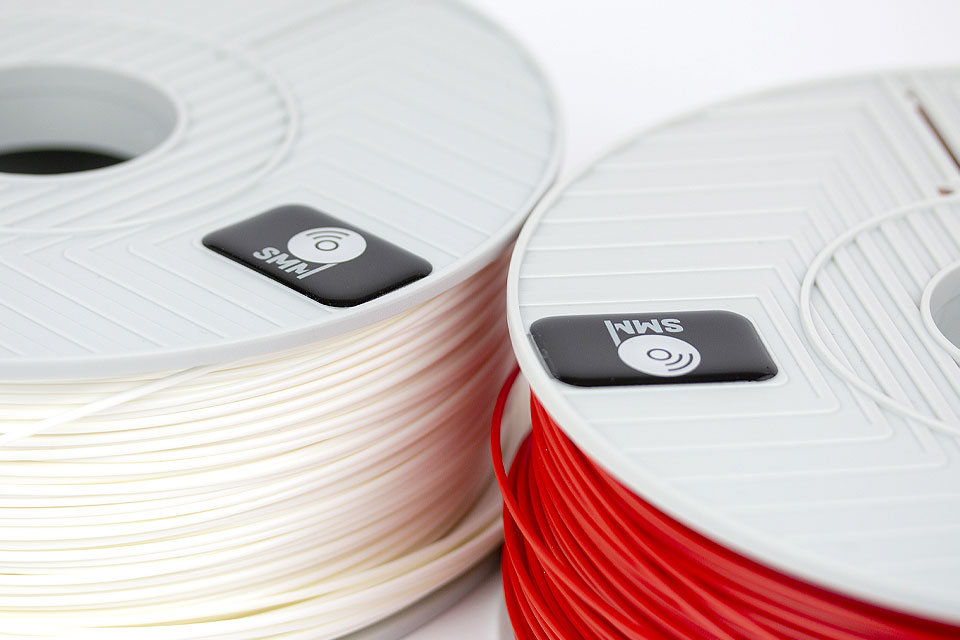

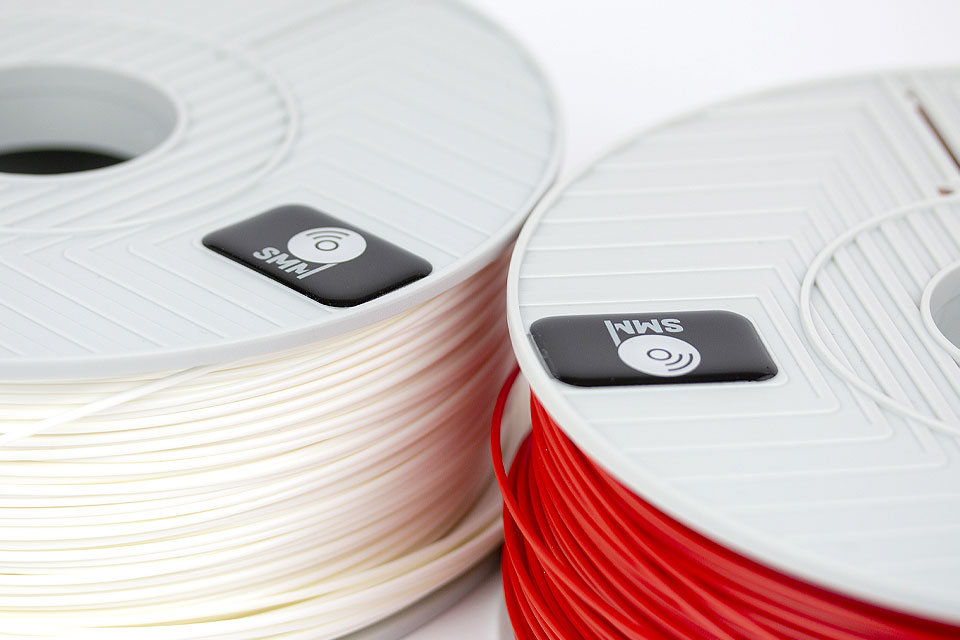

The NFC scanner collects data connected with the filament used during the printing process – optimal working conditions and maximum speed. All the information concerning the weight, type, colour and percentage quantity of remaining filament loaded on a particular hotend.

Smart Material Manager is a intelligent filament and printing environment control system.

SMM consists of a number of solutions:

3D printing is increasingly used in medicine and allows for detailed planning of operations. This makes it possible to select the appropriate operating technique, discuss it in the team and shorten the time of the procedure itself.

The use of 3DGence INDUSTRY F340 allowed verifying the vacuum manifold, which is one of the elements creating a hydraulic system of a pump compartment inside fire engines.

In the process of revitalization, it is important to present the building’s body with a high detail referring to the original design. PANOVA created the complex building model based on archival materials from 1897 in 1:75 scale using 3D printing technology.

Electric auto-revolution can be supported by 3D printing technology! Using 3D printer AGH Racing could test original design of steering knuckle at a very low cost and in just two days.

High-performance polymer from PAEK family which offers a unique combination of properties.

High-performance polymer from PAEK family which offers a unique combination of properties.

Soluble support material. Clear the supports without the risk of damaging the model.

Combines the features of acrylonitrile butadiene styrene and polycarbonate copolymer.

Produced using multi-wall carbon nanotube technology and a highly precise extrusion process.

You are not convinced that you will benefit from 3D printing?

3DGence specialists will identify possible areas of application for 3D printing in your company and show what savings can be generated by using this technology in the long term.

Technological audit is a free of charge service.

Print technology

FFF

Build volume

260 × 300 × 340 mm (26 520 cm3)

Min. layer height

40 μm

Number of printheads

2 per module

Nozzle diameter

0.4/0.4 mm or 0.6/0.6 mm

Filament diameter

1.75 mm

Printhead temperature

500°C

Buildplate temperature

160°C

Chamber temperature

85°C (active heating)

Filament chamber temperature

70°C

Power requirements

230V

Max power draw

2700W

Communication

USB drive, SD card

Slicing software

3DGence SLICER 4.0

Filtration

Filtration unit

UPS device

Yes, optional

Others

software access overdrive – remote shut down

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.