Prototyping

Case study

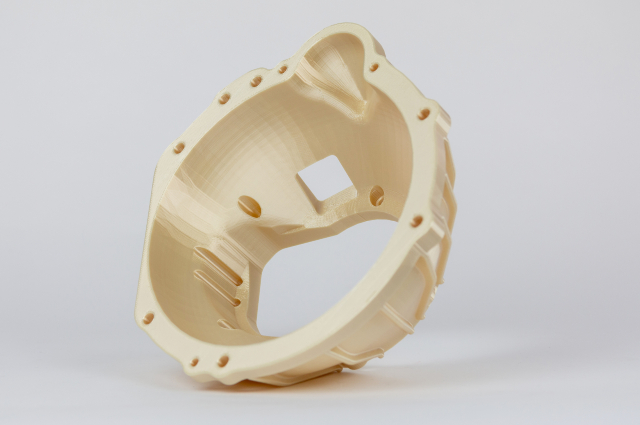

The full-scale gearbox prototype made with ULTEM™ was used for functional laboratory tests.

The use of this material, which can withstand high temperatures and oil in the gearbox prototype, allowed the rest of the components to be fully mounted for a complete assembly.

ULTEM™ has low thermal expansion compared to other plastics. Therefore, the system is unlikely to leak during testing.

Furthermore, the test engineers did not have use external suppliers to produce the part. This allowed for full design control to be kept within the company.

Whether speed to market is critical, or in times of disruption, 3D printing can help you with many different applications through the use of many functional and engineering materials. If you need help deciding which filaments will suit your application or project, please consult with our experts: [email protected]

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.