3DGence CONNECT™

Engineered to meet the Industry 4.0 requirements, CONNECT links together the 3DGence ecosystem of hardware, software and materials to deliver end-to-end traceability of the additive manufacturing process.

Engineered to meet the Industry 4.0 requirements, CONNECT links together the 3DGence ecosystem of hardware, software and materials to deliver end-to-end traceability of the additive manufacturing process.

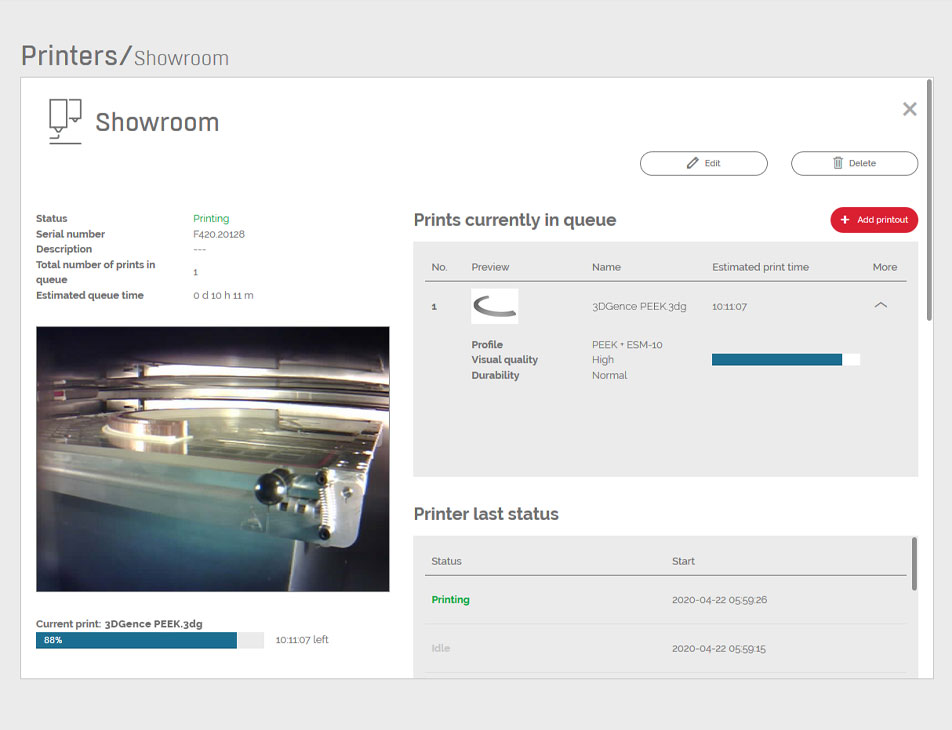

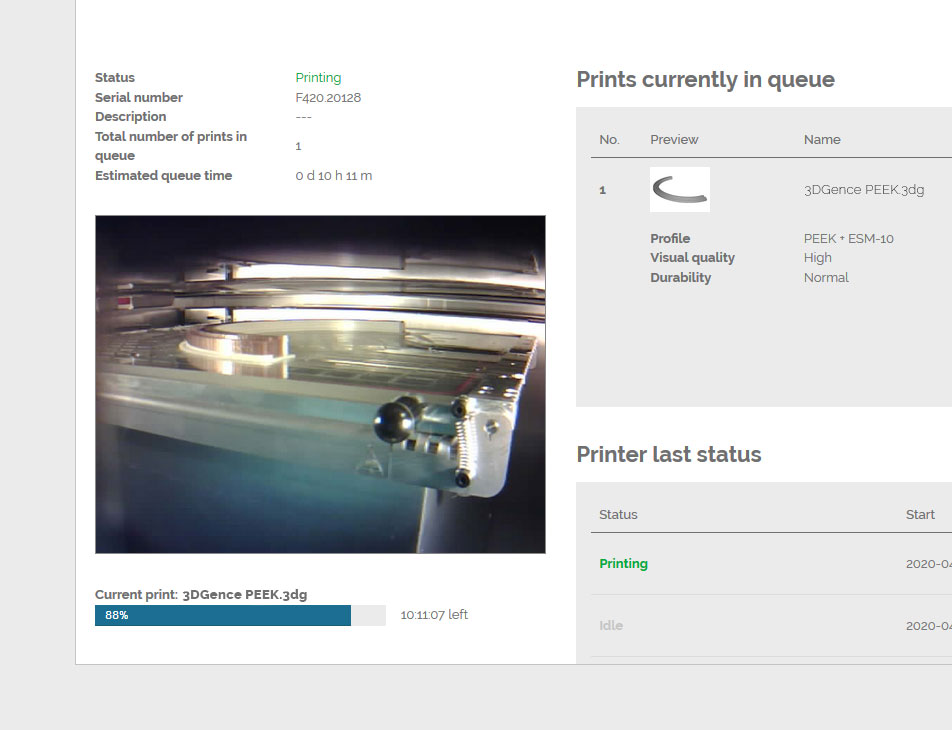

Start, cancel, or queue multiple print jobs. Achive full control of the 3D printing process and print job order, even on multiple printers, as well as real-time monitoring of the machine and print status.

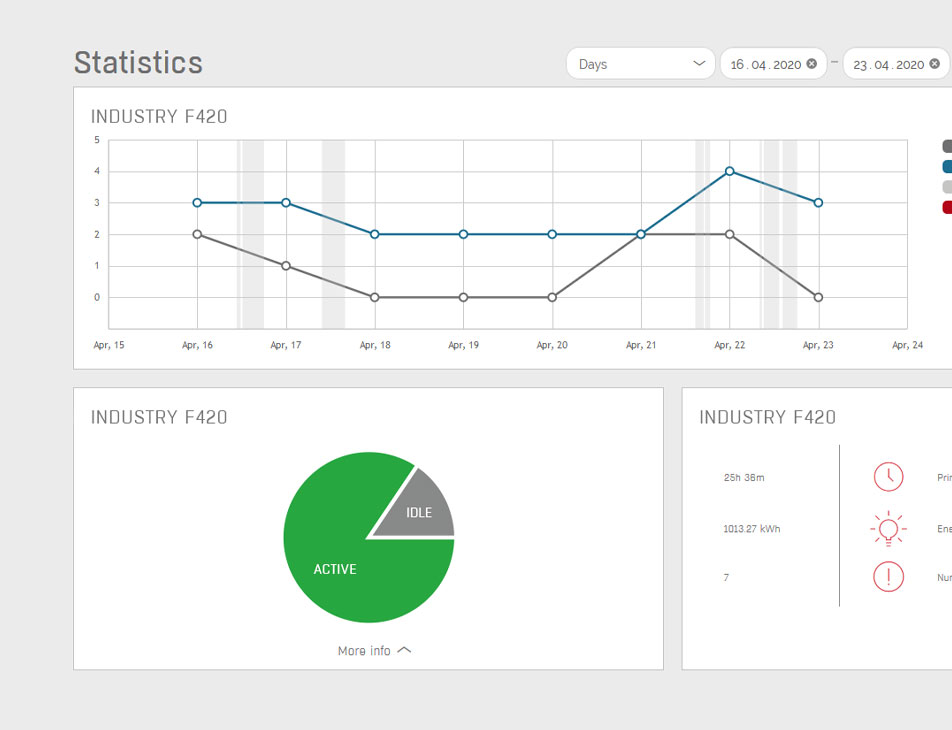

The software aggregates and presents the machine and material usage statistics. All the user data transferred via 3DGence CONNECT system is securely transmitted with asymmetric encryption.

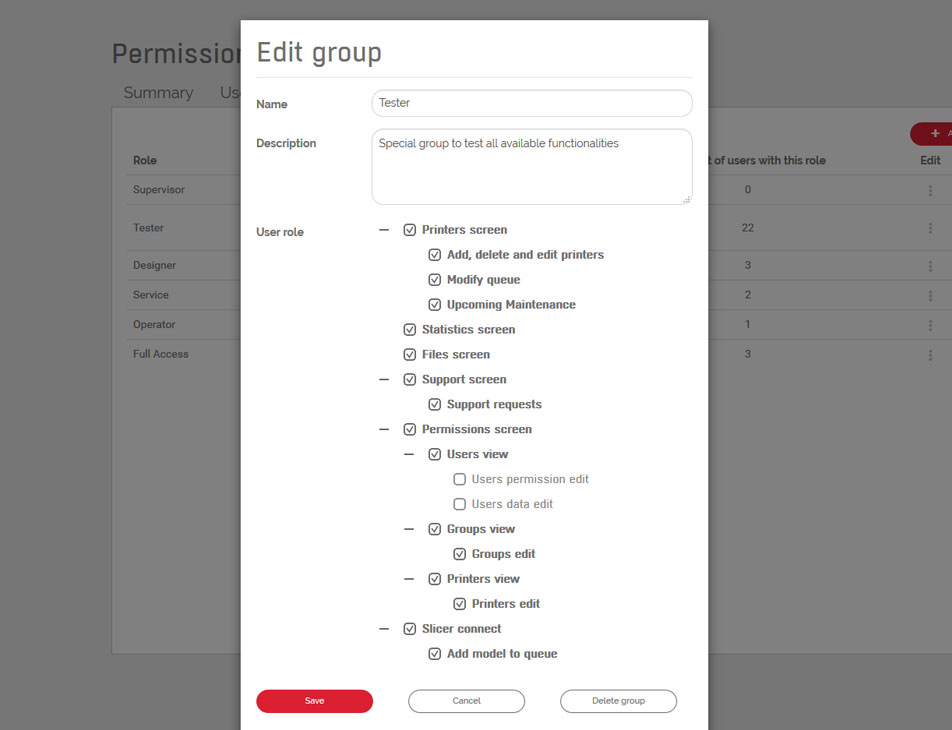

The access to different 3DGence CONNECT system functionalities can be restricted to predefined user groups. The administrator can differentiate the user groups in order to enhance process and data security.

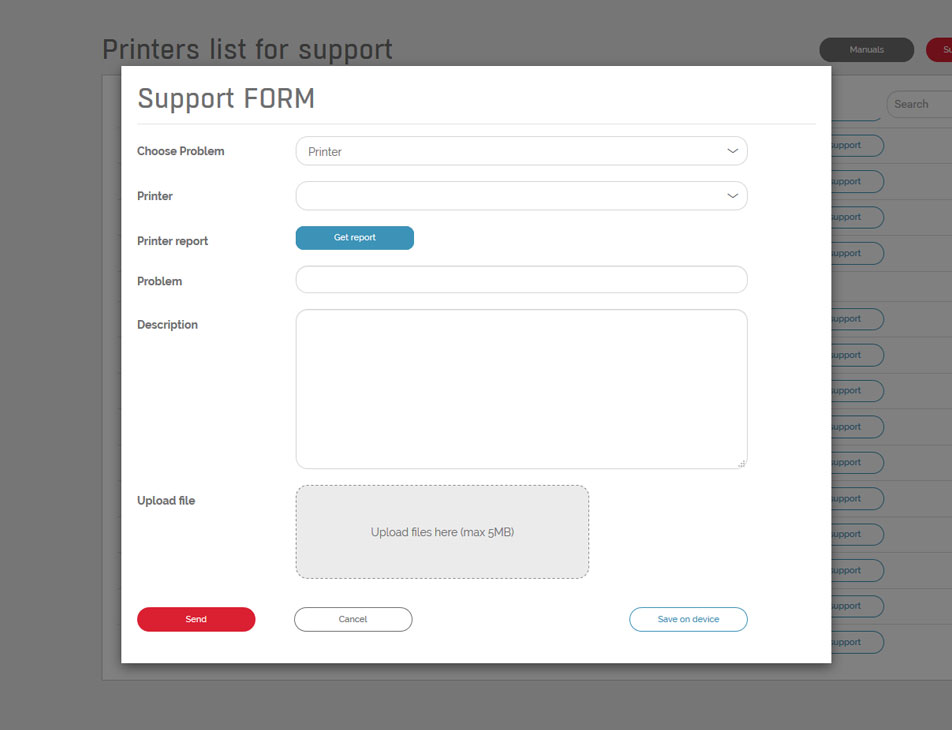

When access is granted, the 3DGence support team may use the 3DGence CONNECT system software to access, diagnose, and provide customer assistance remotely.

Remotely check the current status of the print job and see a live picture of the build chamber interior.