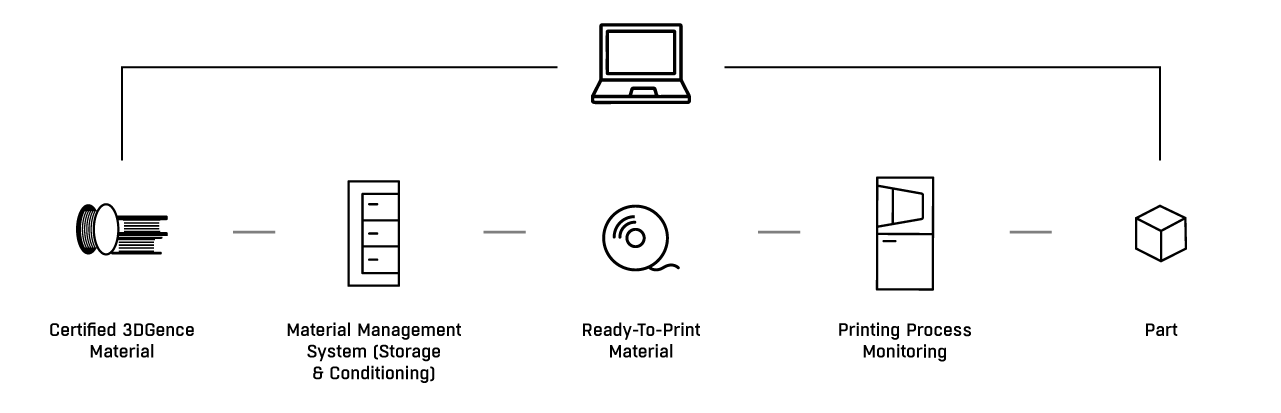

Automate the correct preparation of your materials for accurate, strong, and high-quality parts. The MMS enables connected productivity, repeatability and full traceability of the printing process.

The most versatile industrial 3D printer capable of 3D printing with the widest range of engineering materials, certified by TÜV Rheinland. Designed to produce high-quality and durable parts with complex geometry.

Contact now and get free modules PRO and HT1.

Submit the form and get your special offer.

Material Management System (MMS)

3DGence MMS automates material storage, preparation, and post-print annealing – making successful printing of Ultra-Polymers like PEEK, ULTEM™, and Composites accurate and simplified.

As the shift from prototyping to end-use parts has become a reality through industrial grade 3D printers and advanced materials, automation and pre-configuration ensures print success.

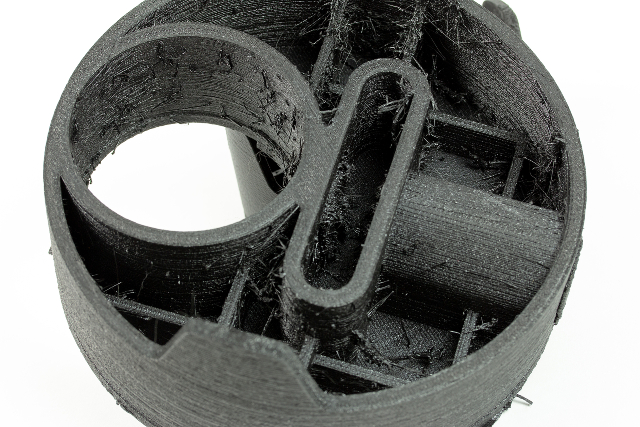

Improper handling and preparation of materials can result in moisture creep, print failures, warping, and low visual quality – resulting in inaccurate parts and significantly reduced productivity.

Ensure print productivity, part integrity, and the highest quality with our Material Management System.

• Select materials from our Certified Open Material Database and register them to get full material traceability.• Each spool of material purchased from 3DGence is equipped with an NFC tag with a Unique ID. Once selected, the material is registered by scanning to the MMS and integrated with 3DGence CONNECT™.

• The material associated to the print is traced in the print process, and can be viewed on the MMS or 3DGence INDUSTRY line printer

• The associated material and print process is registered and stored in process logs, accessible in 3DGence CONNECT.

Parts printed from materials that are not stored properly have lower mechanical properties and visual quality

MMS pre-programmed preparation modes ensure durable and accurate prints without visual defects.

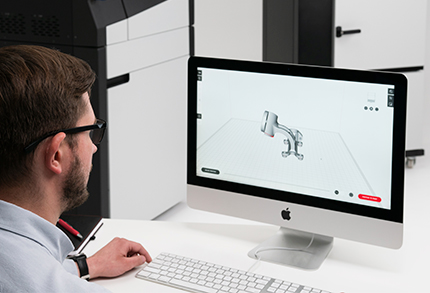

3DGence CONNECT is an evolving, fully interconnected system bringing together software, hardware, materials, and process control.

3DGence provides system control and traceability over the entire print process – from material to part.