The 3D printing market keeps evolving and offering new solutions for clients. To choose the best 3D printer in 2022, it is no longer enough to simply identify a working field and operating temperature. Here is a comparison of industrial 3D printers: what to look for when shopping.

Last year, customers were most often guided by parameters such as the size of the working field, the materials handled (PEEK, which requires an extruder temperature of more than 300℃, was very popular), and the ability to automate certain processes.

According to one of the most respected media sources in 3D printing, All3DP, the most popular 3D printers in 2021 included models such as the Stratasys F900, 3DGence F421, WASP 4070 Tech and Cincinnati MAAM.

Talk to 3D printing experts

Before you buy a 3D printer, it is worth checking its exact specifications and not just taking the working field into account. Sometimes even a slightly smaller printer will perform better if it offers greater integration with software, as well as a higher heating temperature.

Here is a list of features to look out for when choosing a 3D printer.

The area of the print chamber will define how large the print can be. Typically, the larger the chamber – the better. But it will also be linked to the price of the device. The best 3D printer is one in which we will be able to create many parts at once, or in which we can fit the largest print we need.

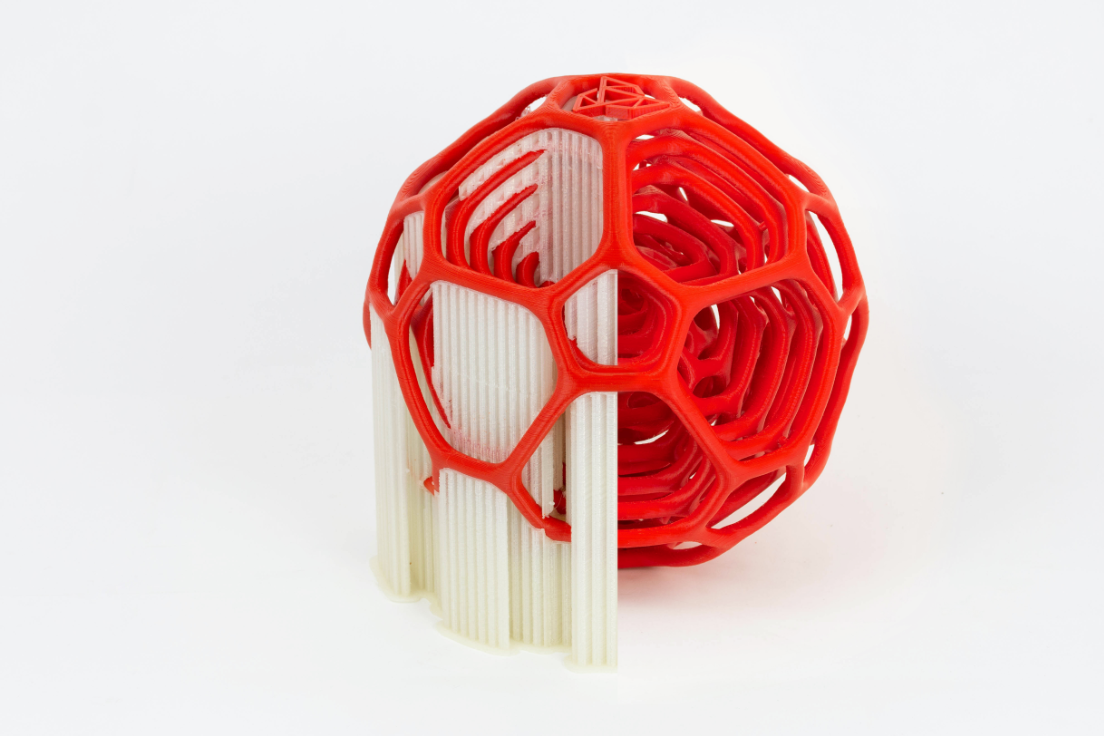

If the desired device does not meet the most important criterion, i.e. the chamber area, it is still too early to give up. Depending on the material, some prints can be created in parts and later glued together. However, a print made in this way will be more susceptible to damage.

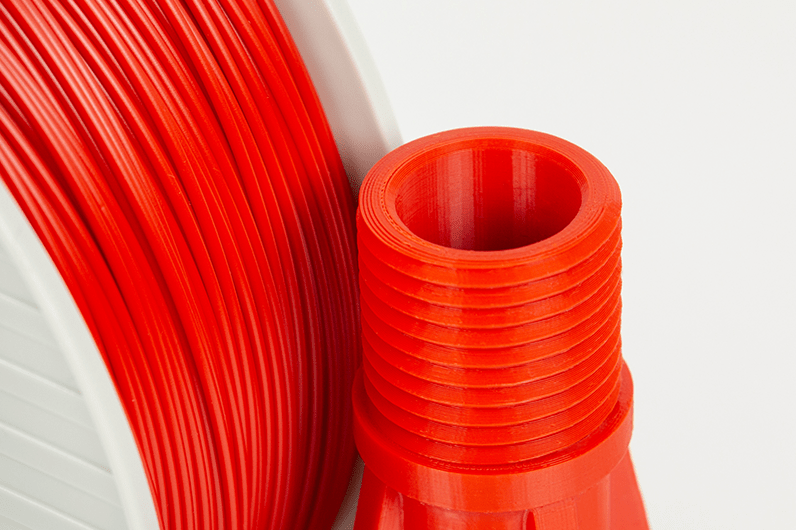

It is becoming increasingly difficult to find 3D printers on the market that can cope with the most common filaments, such as ABS, PLA or PVA. However, if you are buying a printer for industrial use, it is worth considering a unit that will offer a higher heating temperature.

To print with ABS material, it is sufficient for the head to reach the temperature of 250℃. Please note that when printing with ABS, the chamber should also be closed.

Specialised materials such as Ultem and PEEK require much higher heating temperatures. With PEEK, a head temperature setting of 370-410℃ is recommended, while Ultem requires a range of 350-380℃. When comparing 3D printers, it is therefore important to bear in mind that if we are going to print using those materials, we need a head that heats up to 400℃.

Industrial 3D printers also often offer a separate chamber for filaments where it is possible to dry them. Moisture can adversely affect print quality, so when comparing 3D printers it is worth looking more favourably at those that have a built-in system for drying the material before operation.

It is also worth checking out the additional capabilities of the filament drawers. Some manufacturers incorporate additional solutions, such as automatic material feeding.

Talk to the 3Dprinting experts

You should also check how accurate the prints are before deciding on a 3D printer. The best 3D printer is one with which you will not have to spend a lot of time on post-processing. When it comes to industrial printers – almost every manufacturer offers test prints. Before purchasing, it is therefore possible to make an appointment with a sales representative to test the product’s capabilities.

Repeatability is a key feature in low-volume 3D printing. This is because we do not want every print to look different, especially when testing successive iterations of the product. The printer software, which interprets the G-code file, accordingly, is responsible for the vast majority of this.

When choosing an industrial 3D printer, pay attention to how repeatable the process is and whether successive prints vary.

Nowadays, it is increasingly common for 3D printer manufacturers to offer an extended 3-year warranty for the devices and free maintenance.

Such a solution is used, for example, by the Polish manufacturer 3DGence, which offers a support department response of no more than 24 hours and expert user support as part of its warranty. In this way, not only do we get rid of unwanted faults but we are also guaranteed a quick solution to machine operation problems.

The 3-year warranty for industrial 3D printers is important, as faults can happen with heavy machine loads in production. The extended support period guarantees the least possible downtime and no additional printer maintenance costs. Sometimes it is worth paying more for an extended warranty rather than only reacting to problems when they arise.

Which industrial 3D printer to choose? It is a good idea to do a simple test before buying to determine whether the selected product is suitable for our business.

Here are the points that a good industrial 3D printer should satisfy:

The 3D industrial printer by 3DGence Industry F421 is the manufacturer’s top-of-the-range device. The main advantages include a dual extruder, a large working area and a security system to monitor print quality. The printer also has interchangeable print modules, allowing you to easily adapt it to your needs. In addition, there is also a separate chamber for storing filaments and a material feeder. Learn more.

3D printer comparison – INDUSTRY F 421

A smaller equivalent, Industry F421 is the solution for those who do not need such a large work area. The F350 model also features an actively heated print chamber, dual extruder and auto-calibration capability. Learn more.

3D printer comparison – INDUSTRY F 350

FabPro 1000 is not exactly an industrial 3D printer, although it could be a slightly cheaper alternative thanks to its size. It operates using the DLP technology, so it does not use plastic filaments but resin materials. The advantage of this device is its speed as it prints much faster than classic FFF printers. However, the small working area may not be sufficient for everyone.

Stratasys is a leading manufacturer of industrial 3D printers. The F900 model is particularly recommended for large-format and batch production as it has one of the largest working fields on the market. This is also linked to the price of the machine – it is available to order and the installation of the device is done by the manufacturer or its agent.

The printers from Raise3D are manufactured in China and this allows them to maintain a relatively low price compared to other manufacturers, and this is not associated with a decrease in print quality either. The Raise3D Pro 3 Plus model is popular due to its size and reliability. The Pro 3 has all the features of the best industrial 3D printers.

The i500 model is the first industrial 3D printer in the catalogue of Zmorph, a Wrocław-based company. Previously, they specialised in multitool printers with interchangeable heads. The Zmorph i500 features a large working area and a range of solutions to ensure high print quality.

Developed primarily for printing with PEEK material, the CreatBot PEEK-300 is quite an interesting proposition among industrial 3D printers. Here, the Chinese manufacturer has taken care of the ability to print with two materials at once. Work area dimensions – 300 x 300 x 400 mm

As you can see – the market currently offers a great many models that differ only slightly from each other. In most cases, unfortunately, you have to choose between the workmanship and the price of the device, although there are manufacturers that have managed to get quality 3D printing at an affordable price.

Thanks to this guide, you have found out which features to look out for in the first place, as well as the most popular products on the market.

If, despite the above advice, you are still experiencing problems choosing the right 3D printer for your solutions, please contact us. Our experts will be happy to provide advice on the choice of printer and 3D printing technologies themselves.

3d printer comparison find more on 3dprinters