3D is a dynamically developing manufacturing technology, which enabled many companies to make significant savings. Lowering of the costs of short production series, tools or, particularly, prototypes is possible at any company. In each operation areas may be found where measurable savings may be achieved.

How to do it? The question will be answered by 3DGence specialists who support companies in optimising their costs on a daily basis.

Calculation of a 3D printing service takes the maximum of 24 hours at 3DGence and is a basis for carrying out a more accurate cost-effectiveness analysis. 3D printing prices are based on a series of factors, such as volume and size of an object, quantity and type of the material used, or time and working technique when making a 3D printout.

The most important thing to arrive at the cost of 3D printing is to determine material and finishing requirements which make up the cost of a specific part. There are many factors which influence the cost of a printed part.

Before 3D printing starts in the selected technology, the person responsible for starting up a device must make a process simulation and analyse the possible settings of a model for 3D printing. The selection of adequate temperature settings for the respective material, the speeds or additional parameters of the process is of key importance to produce a most durable part. The initial costs of 3D printing include also the preparation of a device to work, implementing of the printing materials or the measures creating the proper 3D printing environment.

The most important factor in calculating the costs of a 3D printout is the size of the object and the place needed in the device for printing the same. Larger objects are more expensive due to the space they take and, in consequence, the time needed to arrive at a complete printout.

Request for a 3D printed sample for your company

The printing time is determined as the working hours of a 3D printer in the respective technology. The costs include all the indirect the indirect costs related with the utilisation of the production capacity of a 3D printing farm.

The 3D printing process commences immediately after the order has been approved. The lead time specified by our lab includes also the time of delivery by courier mail (24 hours).

3D printing time depends mainly on the selected material

3DGence, as an expert in 3D printing technology may propose a vast material portfolio to its customers, stating from standard plastics, such as ABS or PLA, and ending with aluminium and titanium alloys.

Our team of engineers takes an individual approach to 3D printing inquiries, analysis the needs and proposes the solutions which may bring measurable savings in the respective sector. Contact us: [email protected]

3D printing has many advantages, however, cost reduction is of key importance to many companies, which includes very low cost of manufacturing short series of products or individual elements.

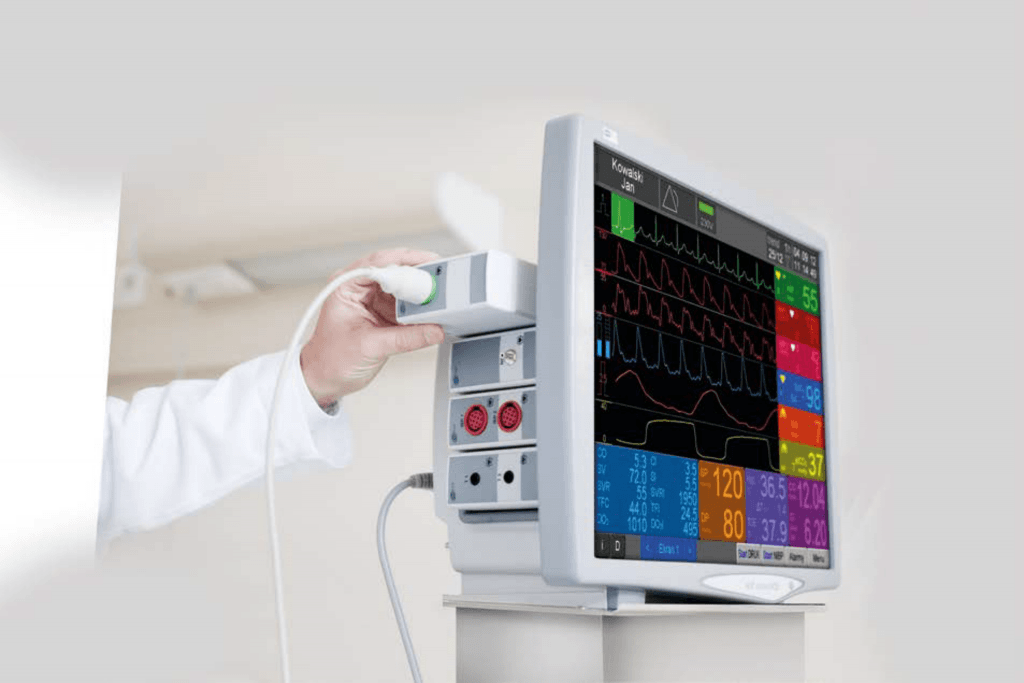

Emtel, a manufacturer of medical devices, managed to reduce the costs of prototypes even by 90% with 3D printing. In 2018 the company decided to design a new model of a cardiac monitor. 3D printing proved to be the most adequate technology to make a prototype of the casing, with regard to the price of manufacturing

.Delivery of the model by third parties was the cost of approximately PLN 2,000. And at the stage of forming as much as 3 versions of the same model must be prepared.

Check 3D printing services for your organisation