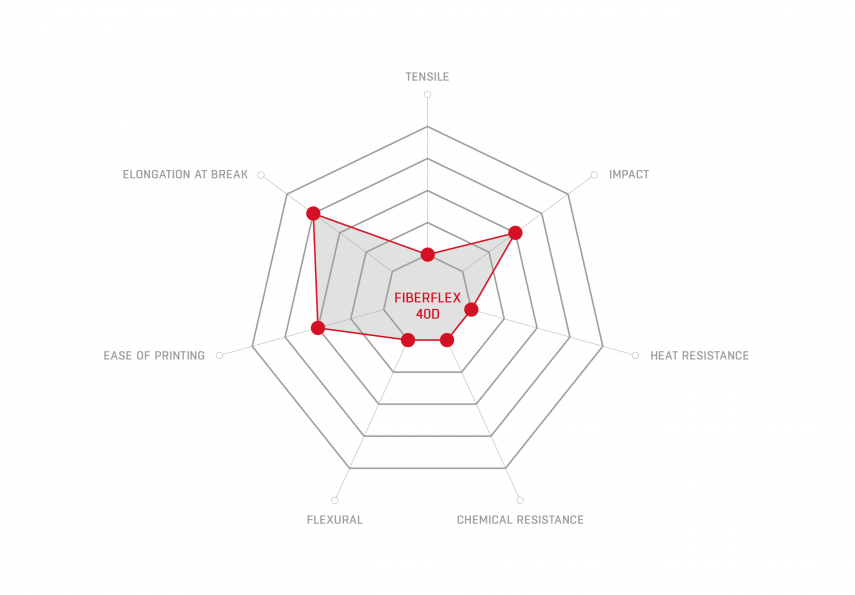

Fiberflex is an elastomer filament with the Shore hardness of 40D

![]()

![]()

![]()

![]()

Printing process is easy to set up and the printing speeds of even 45mm/s are achievable while using the direct extruder.

It can be used to produce the machine parts that are bent frequently, for the elastic joints or gaskets.

Despite its flexibility, the material also maintains high stiffness after the printing process.

Fiberflex 40D has high impact resistance in low temperatures and very good thermal, chemical and abrasion resistance.

Low volume production

Additive manufacturing is frequently more cost-effective than other legacy manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time tp market.

End Use Parts

In many instances the mechanical properties and surface characteristics of 3D printed parts meet and exceed the customer’s expectation, allowing their use in the actual product.

Prior to launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components, accelerating the iterative development cycle and time to market.

We will help you to choose the right material