3DGence 3D printing services

- Your production line equipped with 3D-printed parts.

- Professional project analysis including 3D modelling, file validation, technology and material selection.

- Over 1000 satisfied customers across the world.

Contact info

Get in Touch with us!

Your idea is safe [we can sign an NDA]

Our 3D Services

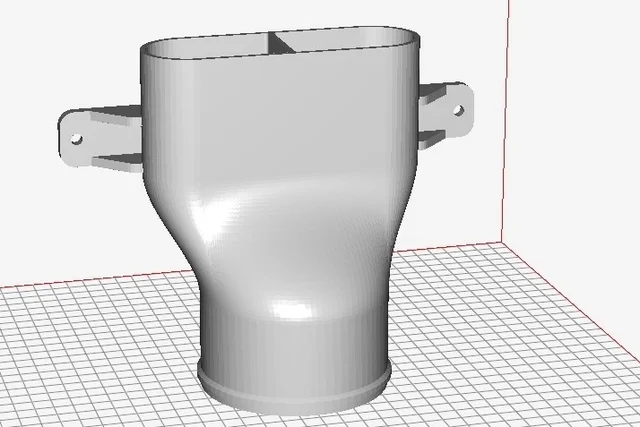

3D printing

Use the 3D printing services. Together with us you will implement a project in any 3D printing technology. We print spatially in FDM, SLS, SLA, DMLS and PolyJet technologies. Thanks to our experienced engineers and an extensive 3D printer park, you can be sure that your 3D print will be of the highest quality.

Contact us and find out what the price of your 3D model will be printed.

3D scanning

Thanks to the latest technologies, 3D scanning allows you to create extremely precise scans with an accuracy of up to 0. 05 mm. Measurements are made for both small and large models, from 0. 05 m to 4 m. It is possible to obtain a detailed 3D model for almost every object, which at a later stage can be processed in a CAD program and printed on a 3D printer.

Consulting

Advice on 3D printing technology is a service within which appropriate printing parameters and optimal technical materials will be selected. The first stage is to identify the customer’s needs and choose the appropriate 3D printing technology. Then the appropriate materials and parameters of the printing process are selected. The final stage is to create a free valuation of the 3D printing service in the selected technology.

Post-processing

In order to achieve the desired visual and tactile results, which increase the added value of 3D printing, both chemical and mechanical processing is offered. Our modeling work offers: folding or gluing prints, chemical treatment, mechanical treatment, UV exposure of resin prints, rotational polishing (SLS), surface dyeing (SLS), mudding and sanding, painting and varnishing.

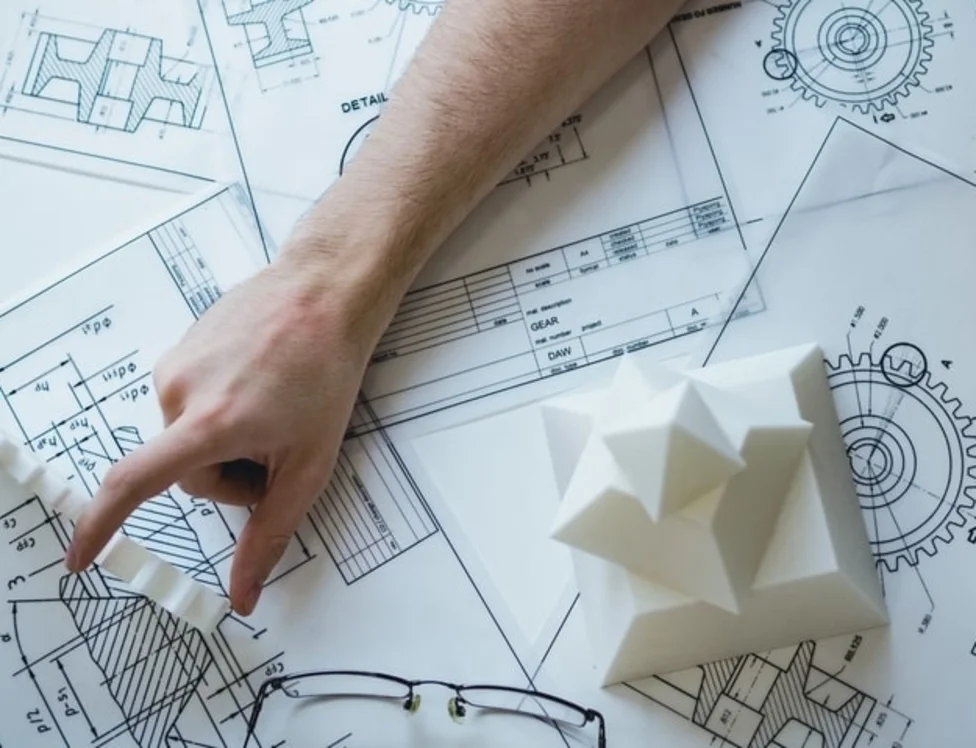

3D modelling

The process of creating CAD models is based on the technical documentation sent by the customer.

Then a digital 3D model is generated, designed for later printing in the selected 3D printing technology. The formats most commonly used to create digital models are: IGS, OBJ, STP, X_T, STL, AutoCad, CATIA, STEP, REVIT, IronCAD, FreeCAD, SAT, PARASOLID, NX, Blender, ACIS, 3DMAX, CREO, ArchiCAD, IGES, Inventor, SolidEdge, SolidWorks, Rhino, ThinkDesign, ZW3D, SketchUp and others.

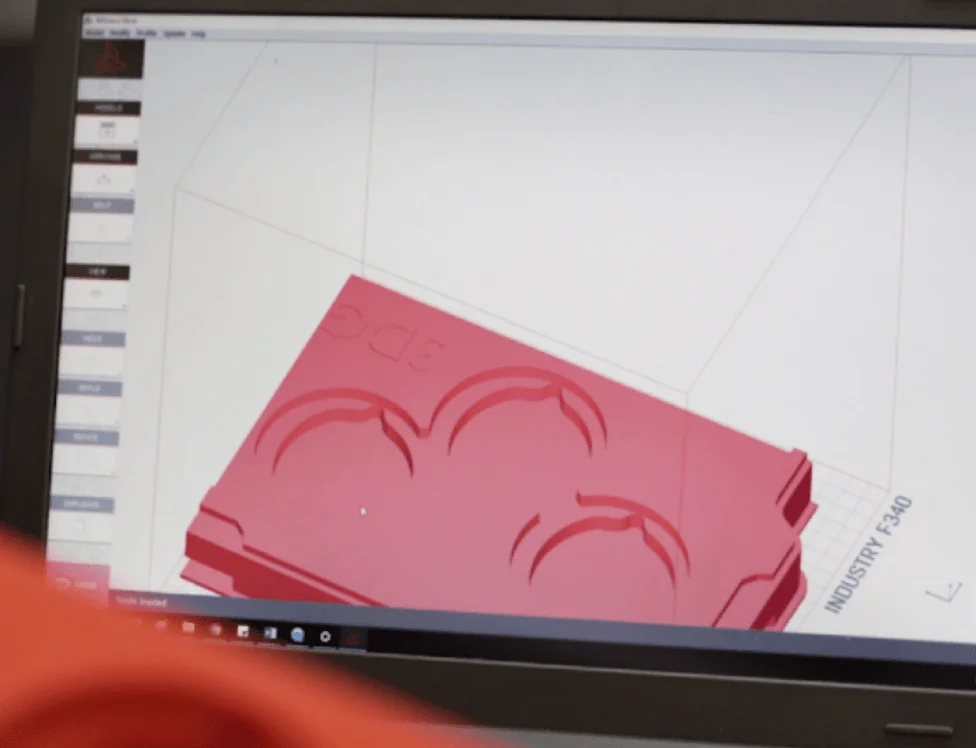

3D printing service cost

3D printing prices are based on a series of factors, such as volume and size of an object, quantity and type of the material used, or time and working technique when making a 3D printout. You can read more in our article, see examples or contact our experts. Calculation of a 3D printing service takes the maximum of 24 hours at 3DGence and is a basis for carrying out a more accurate cost-effectiveness analysis.

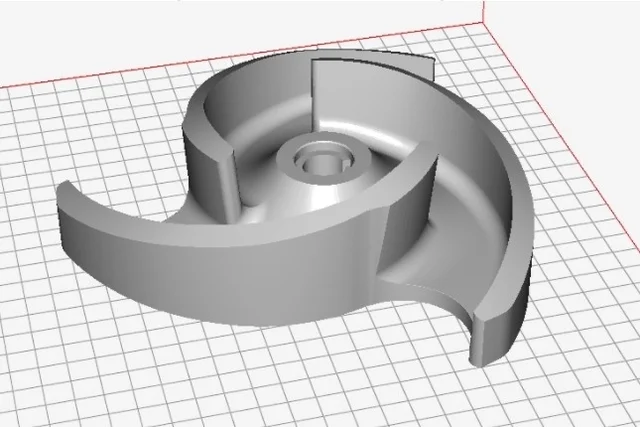

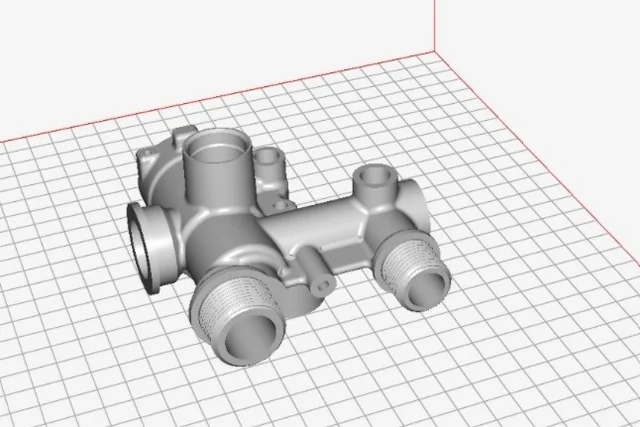

Cost: 240 EUR Time: 14 hours

Dimensions: X=230 Y=103.98 Z=180

Cost: 135 Euro Time: 23.5 Hours

Dimensions: X=166.29 Y=178.18 Z=56.34

Cost: EUR 120 Time: 27 hours

Dimensions: X=103.5 Y=107 Z=59.3

SDS

Use the 3D printing services. Together with us you will implement a project in any 3D printing technology. We print spatially in FDM, SLS, SLA, DMLS and PolyJet technologies. Thanks to our experienced engineers and an extensive 3D printer park, you can be sure that your 3D print will be of the highest quality.

SLS

Use the 3D printing services. Together with us you will implement a project in any 3D printing technology. We print spatially in FDM, SLS, SLA, DMLS and PolyJet technologies. Thanks to our experienced engineers and an extensive 3D printer park, you can be sure that your 3D print will be of the highest quality.

Deutsch

Deutsch Polski

Polski Français

Français Americas

Americas