Technology

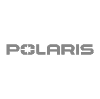

Stereolithography SLA

- Produce highly accurate, isotropic, and watertight parts

- Wide range of advanced materials with fine features

- Great option for applications requiring tight tolerances and smooth surfaces

Contact info

Get in Touch with us!

Your idea is safe [we can sign an NDA]

Order process

-

Submit a request

-

Benefit from proffesional support in the selection of technology and materials

-

Order your parts

online -

Receive

your parts

Materials

General Purpose Resins

Engineering Resin Families

Technical information

How does SLA technology work?

- The build platform shifts down into liquid resin.

- Recoater/rollers squeeze resin out from under the part to generate a thin, even layer of resin.

- The laser/mirror combination directs the beam according to the path needed for creating object. The resin solidifies wherever the laser beam hits it.

- The process is repeated layer by layer until the build is complete.

Trusted bY Engineers

Why us?

We operate globally

Backed by a team with years of experience in the field of additive manufacturing technologies, design and machine construction

Trusted by thousands of engineers around the world

Q&A

What are advantages of SLA 3D printing?

SLA is known for it’s ability to produce highly detailed and accurate prints. It’s also is capable of producing intricate and complex geometries that may be challenging or impossible with traditional manufacturing methods. SLA supports a variety of materials, including photopolymers with different properties such as flexibility, transparency, and toughness.

What the printing process looks like at SLA?

The SLA process begins with a digital 3D model, typically created using computer-aided design (CAD) software. Than the digital model is then sliced into thin layers using specialized software. A liquid photopolymer resin is chosen based on the desired properties of the final object. The SLA printer consists of a build platform and a resin tank. The build platform is where the object will be gradually constructed, and the resin tank contains the liquid photopolymer resin.The build platform is lowered into the resin tank just below the surface of the liquid resin.A UV laser beam is directed by mirrors to trace the first layer of the object onto the surface of the liquid resin. The UV light selectively solidifies the resin layer according to the sliced cross-section of the 3D model. After a layer is solidified, the build platform is slightly raised, and the process is repeated for the next layer. Once the printing is complete, the object is typically not fully cured and might still be somewhat sticky. It undergoes a post-processing step where it is fully cured using UV light. Once the printing is complete, the object is typically not fully cured and might still be somewhat sticky. It undergoes a post-processing step where it is fully cured using UV light.

What is an STL file?

An STL (STereoLithography) file is a widely used file format for representing 3D models in a format that is suitable for computer-aided design (CAD) and 3D printing. STL files are commonly used in various applications, including 3D printing, computer-aided design, and computer-aided engineering. They provide a simple representation of the surface geometry of a 3D object and are compatible with a wide range of 3D modeling and printing software.

3DGence Services – FAQ

As the Additive Manufacturing industry has quickly evolved, many organizations are evaluating options and technologies to speed up their design and engineering needs. Choosing the right technology, material, and application can be a daunting and expensive task.

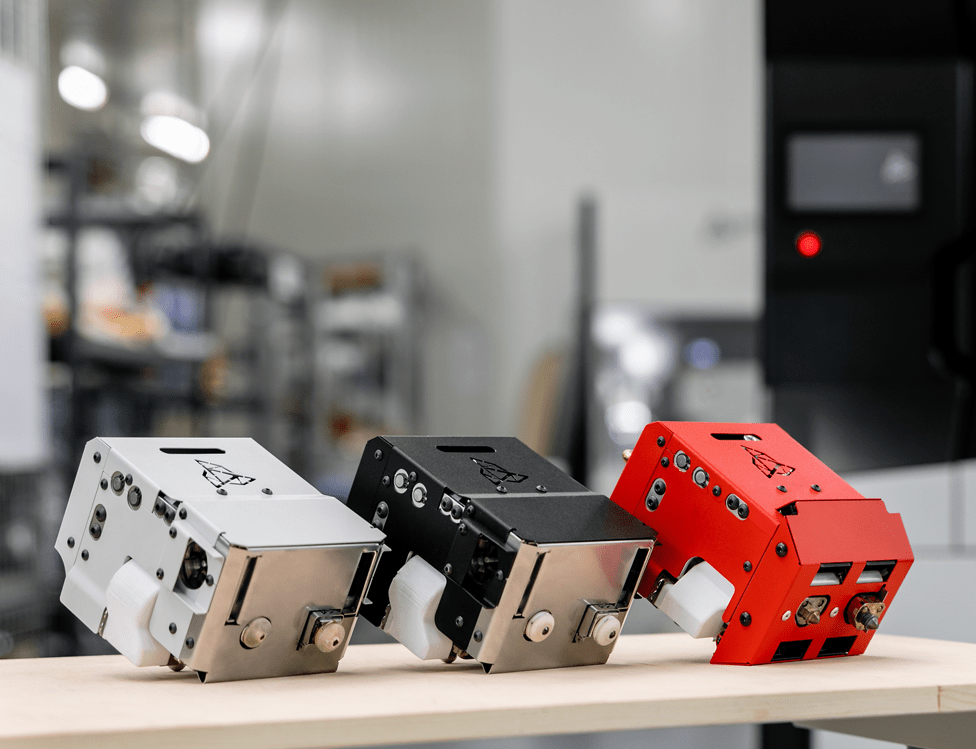

Printing module

Manufacturers of machinery used in various industries have been focusing their attention on the production of modular construction machines for many years. As a user, we get a machine in a basic configuration, and then, depending on our application and needs, we expand the purchased device with dedicated modules or tools specialized for a specific range of work.

3DGence Services

Professional Additive Manufacturing Services are another option qualifying, evaluating, and adopting 3D printing technology to your business needs. Along with top-notch hardware and a wide range of materials, our company offers 3Dprinting services using multiple technologies. Read this article and explore the unlimited possibilities of AM services available at 3DGence. Read more

Custom manufacturing services

Automotive

Aerospace

Medical

Architecture

Production

Deutsch

Deutsch Polski

Polski Français

Français Americas

Americas