For a long time, manufacturing has faced the waste of raw materials, time and money, which is exemplified by spare parts. This is where lean manufacturing comes in, a concept that helps the industry, helping to slim down the entire manufacturing process and take care of costs. 3D printing can become the modern answer to the challenges faced by factories and lean management companies.

The use of LEAN tools and principles allows us to better manage and organize the work of our company. One of the main ideas of this concept is to quit wasting resources, such as materials, time and money. How does the use of 3D printers fit into this trend?

Lean manufacturing involves creating a new product faster, using less tools, space and workload.

Introducing the idea of lean manufacturing requires a careful examination of the factory processes, material flows, order completion, etc. This idea can be used to take steps to eliminate waste. Usually this task is assisted by new technologies, especially different IT solutions. However, the industry has gained a new ally in eliminating excess and manufacturing losses, which is 3D printing.

Get the 3D printed parts you need

For many recent years, the tool manufacturing process has been based mainly on machining technology, which is very material and time-consuming. To manufacture even a small item sometimes requires the involvement of even several people. The problem is slightly alleviated if you have your own tool room. Not all businesses can afford these kinds of costs. When it is necessary to outsource an item, companies risk extended lead times and increased expenses.

The possibilities of using 3D printing in manufacturing companies are immense. Especially when it comes to toolmaking. An industrial grade 3D printer, such as 3DGence INDUSTRY F340 or INDUSTRY F421, can be used to make various types of gauges, testers, spacers, etc. inhouse. What are the advantages of a 3D printer in the company? Inhouse printing of items using the FDM/FFF technology can reduce the lead time from a few weeks to several hours. Moreover, the total cost is significantly reduced, limited to the cost of material only. The prices of materials vary, but the cost of printing from such filaments as PLA or ABS is often no more than several dozen zlotys.

Any work on a new of a product version may often require several attempts to create a prototype, interspersed with corrections, modifications, adjusting to meet the requirements, redesigning the production line, and often ensuing downtime in the daily manufacturing operation. That is why it is difficult to prepare a few proposed versions of new products to choose from the most functional or one that best meets consumers’ expectations.

If we are a manufacturer that often works on new products, the use of an inhouse 3D printer brings tangible benefits. 3D printing is even several times faster than traditional manufacturing processes. Industrial machines such as 3DGence INDUSTRY F421 reach speeds of up to 400 mm/s. If you need to make prints in a truly short time, this 3D printer is an exceptionally good solution.

Having a printed prototype and handing it over to employees in charge of launching the manufacturing process, gives them the opportunity to physically test machines, tools, and the designed process before even the first product is made. Such action reduces the implementation time by as much as several weeks, and elimination of process inconsistencies in the early project stages gives significant savings.

Get the 3D printed parts you need

The manufacturing process in each company requires constant access to spare parts of machines and entire production lines. Since companies cannot afford production downtime, they typically store more than they can use at any given time. And this means freezing funds and additional costs of renting warehouse space.

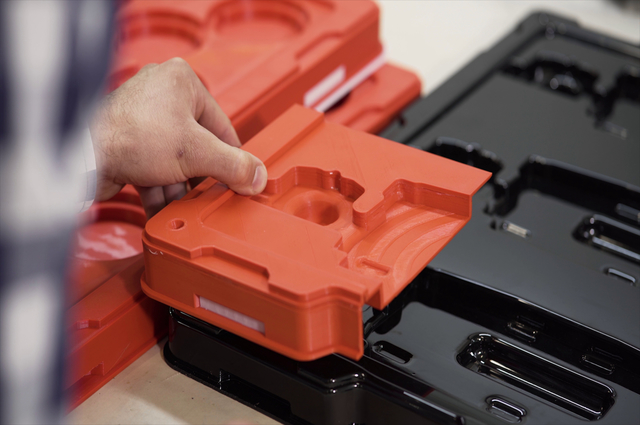

Another possibility of using 3D printing is printing machine parts. Printing parts using the FDM/FFF technology allows you to avoid the need for storing them, as you do not have to keep them in stock. You can simply print them just when they are needed. Minimizing inventory levels is part of the lean manufacturing concept.

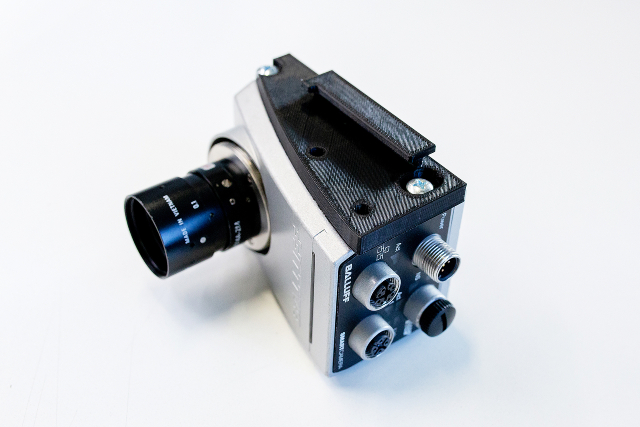

Having a 3D printer that can use engineering materials we can build not only single items but entire tools, e.g. rollers, feeders, connectors, moulds and even casings. The savings are visible immediately.

Depending on the environment to which an item is to be exposed, it is necessary to select the appropriate material and set the 3D printing parameters. For example, if we need an item that will work at high temperatures, even up to 200⁰C, then 3D printing from PEEK material is necessary. This filament is resistant to high temperatures. And when it is necessary to obtain a part resistant to transmission of high forces, it is recommended to use PA-CF material. Knowledge of materials is necessary to obtain parts with the desired properties. If in doubt, ask 3DGence engineers who, thanks to their experience, can advise on the selection of the appropriate material.

When working on the ROI analysis, we tend to forget to include the workforce necessary to be involved in the process of order completion/building an item, and we can translate this saved capacity into other profit-generating tasks. By reducing the lead time, we save money and unproductive time that can be invested in other areas.

Pure Power Sources is a company that manufactures plastic and steel dies as well as elastomer parts. They are mainly used as production line components.

Before purchasing a 3DGence 3D printer, the company faced several challenges. It had strong competition of makers using similar die technologies, offering products at similar prices. And prototypes were made of elastomers using milling machines, which was expensive and prevented using machines for other jobs. The costs also prevented manufacturing small product batches.

Arrange a free technological audit in your company!

3DGence experts will conduct a professional analysis of manufacturing processes and provide a report presenting audit results within a week. Part of it is the answer to the question of what return on investment in a 3D printer can be obtained in your company. Write to: [email protected]