Know 5 reasons why is it worth to invest in a professional 3D printer

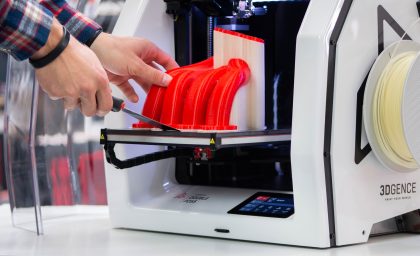

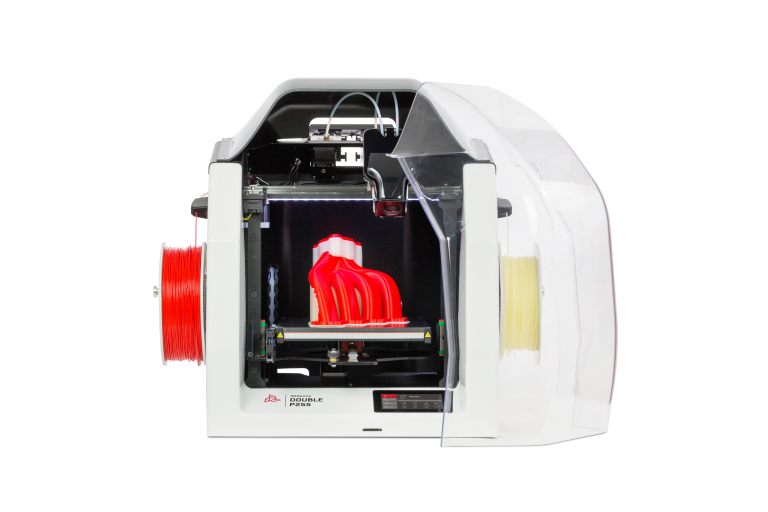

At production companies, a growingly frequent standard is the extension of machine base for new devices, i.e. 3D printers operating in the FDM/FFF technology.

The advantages of 3D printing at manufacturies are many, starting from the possibility of building prototypes, also those of complex shape, and ending with reduction of expenditure on tools or shortening the time of waiting for spare parts.

Most of the people who are responsible for the purchase wish to be sure that a reliable device and one fulfilling the expectations has been selected. What is more, it is not going to break. The purchase of a printer is still a considerable investment for some companies.

It does not come as a big surprise that most of the cheap 3D printers available on the market are built of low-quality components, both as refers to mechanics and electronics or control systems. A major part of such devices are made in China and despite the application of proven engineering solutions, it is very hard to arrive at a satisfactory quality of printouts using them. The application of doubtful quality components in such a device will never allow it.

On the other hand, professional 3D printers from established manufacturers contribute to many years of infallible operation, even in heavy-duty conditions. The largest influence on the proper equipment operation is the use of components which translate into the quality of printing. The kinematic system of the devices is built such as to ensure high rigidity and, what follows, high quality and repeatability of the printed models, whereas electronic components are adequately secured against damage even in industrial conditions. In most cases companies cannot afford downtimes of their machines, and each failure of a cheap 3D printer may elongate the time of production of the needed parts.

The manufacturers of professional 3D printers offer to their customers not only equipment, but – what is extremely important – also the support of a whole group of experts who train, advise and support in service or maintenance. Additionally, it is that group who work daily on the testing of the respective 3D printing parameters. Thanks to that the printer user must not get into the details of plastics processing or deal with the testing and calibration of materials. Printer maintenance or training of the staff to use it means really high costs for companies. Professional manufacturers offer such services in the price of their device, as well as assistance in case of problems with the device and fast reaction in case of failure, which means shorter downtimes in the manufacturing process and lower losses

Implementation of a machine at the company by 3D printing experts

What is more, the suppliers of professional 3D printers offer also the implementation of a printer at the company, i.e. installation of the device, careful verification of its proper operation as well as staff training. The customer may avail of the services of a perfectly prepared service division, both in the guarantee period and afterwards.

Engineering audit at your company

A very good solution for companies before the purchase of a printer is to have an engineering audit done at their company. Such service consists in carrying out an analysis of production processes. It will show what and in which way may be gained when introducing 3D printing at the respective company. The audit is carried out free-of-charge by an Application Team, consisting of engineers who know the manufacturing processes. What is more, they are the employees of the producer of a 3D printer operating in the FDM/FFF technology. This means that their expert knowledge will help answer the question about a return on the investment in a 3D printer at your company.

Request for a free audit at your company

Low initial cost of purchasing a cheap 3D printer may only be apparent. The manufacturers and suppliers of such devices frequently do not offer anything but the very machine. Any further services or improvements must be paid additionally. Many people are not aware of the hidden costs they may face when using a device before they have purchased a 3D printer. The maintenance of a printer may prove to be more costly than assumed by the manufacturer at the time of purchase.

Savings from purchasing a cheaper printer will soon be highly exceeded by the costs of repairs, losses resulting from the downtimes in the manufacturing process or the necessity of repeating printouts. Therefore, considering the purchase of a 3D printer, it is worth to have a look on models from a higher, professional shelf. What is more, the producers of more expensive devices offer a broad range of after-sale services, which are not additionally billed to the customer.

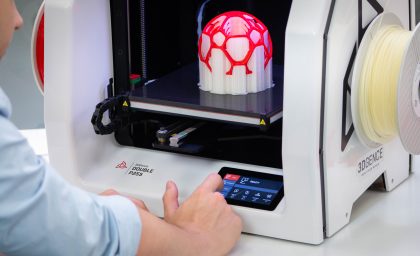

The dimensional accuracy of printouts is a key factor when creating not only prototypes but also gauges or final elements. The manufacturing of the needed parts with the use of cheap 3D printers might mean that the printed element significantly departs from the expectations. Industrial 3D printers offer high-speed printing and high output while maintaining high dimensional compliance and quality of the printed models. The 3DGence INDUSTRY F340 printer, thanks to its heated printing chamber which may reach the temperature of 85°C, creates models of the assumed parameters. For many companies, the printout exactness is of key importance.

For example, Emtel – a manufacturer of medical devices – when preparing a new casing for a cardiac monitor expected accuracy of at least 0.1 mm, particularly in the places of assembly holes. With the use of a 3DGence printer, the company could verify the critical dimensions of the design when preparing a prototype.

Consult your project with 3D printing experts

A cheap 3D printer differs from that of a higher shelf with incomplete compatibility with dedicated software or filaments, which are not always correctly printed thereon. The manufacturers and suppliers of professional 3D printers should provide their customers not only with devices but also tested materials which will be compatible with the equipment. Further, ready material profiles may facilitate the setting of parameters in the respective software.

For a customer it means significant savings in terms of time. Printer operator training is much shorter because there is no need to determine the printing parameters for achieving high quality printouts.

At 3DGence, a dedicated team of the R&D Department constantly works on material profiles, to relieve the customer of the necessity of knowing the methods of plastics processing or even as much as 300 printing parameters which need to be set in order to achieve the expected 3D printing results. It is a guarantee of the possibly highest quality of models printing.

The case is not to buy a device which will soon prove to be hardly effective and will generate more and more costs. Such situation will only discourage people from the use of engineering novelties in production processes. Therefore, when selecting a printer, price must not be the only factor. Low initial cost may be tempting, but will also result in an avalanche of problems when using the machine.

Higher-shelf devices, created and serviced by specialised teams who perfectly know the market, the manufacturers’ needs and the trends in the international 3D printing sector, not only guarantee the convenient use of the printer, printouts compliant with the expectations, and high quality of equipment and the printed elements, but also support, training, advice and assistance by experts at every stage of implementing and using a printer at the company.

Only highly professional equipment and materials will contribute to problem-less printing of even the most geometrically complex, durable and flexible elements, which will become basis for prototypes or even the final products. It is worth remembering that 3D printing is now used in many sectors all over the world. We get on board of planes furnished with printed parts, we drive cars with elements produced in 3D technology, we use printed tools. More and more frequently 3D printing is used by doctors, transplantologists or dental technicians. The developing technology contributes to printing growingly stronger and larger parts.

Such leap in 3D printing applications would not be possible if the manufacturers did not use proven professional 3D printers. It is an investment which may bring a hundredfold return. This refers to the entrepreneurs and the whole societies which may avail of new opportunities, materials and elements improving their quality of work and life.

Benefit with experience and knowledge of 3D printing experts. We will help you to choose proper solution for your need. Write us: [email protected]

Do you still need help choosing your 3D printer?