Worldwide pandemic multiplies the problems in the supply chains, especially in sectors such as manufacturing and logistics. The spread of coronavirus has caused the disruptions in many plants, broken supply chains and prevented production at many industrial factories.

This time of global crisis forces most companies to review their current working methods and consider implementing new tools and technologies. Such as 3D printing.

A manufacturing line downtime may occur in case the supplier of a part fails. Such situation exposes companies to financial losses which may grow with time, when awaiting a replacement. It may even last a few weeks. Finding a new local supplier, in a crisis situation, can be a big challenge.

Therefore, it may be much better to use 3D printing in your own company. This will reduce downtime due to missing parts. Owing a 3D printer is a perfect alternative for a fast access to spare parts needed for the operation of a given device or the whole engineering line.

3D printing technology enables producing any type of elements which come into a majority of mechanisms, e.g. engines or various systems. 3D printers provide the opportunity of preparing even the most non-standard and hardly available custom-made elements in a short time. Thanks to this solution we are not dependent on external suppliers, which is a big advantage in a crisis like this.

The use of 3D printing technology allows parts to be made where and when they are required, without very expensive moulds. Additionally, if we are able to produce elements in our company, we do not have to pay for transport.

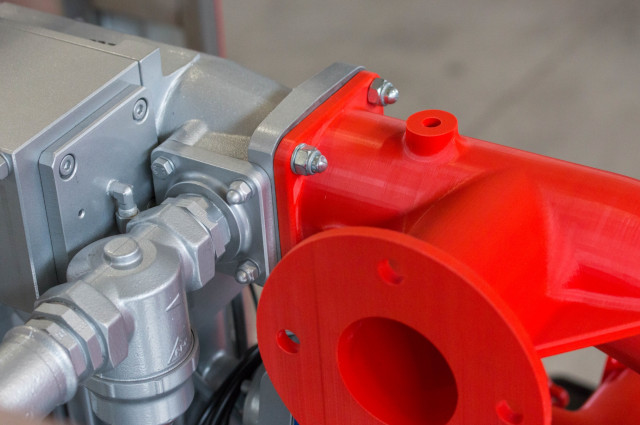

Many components used in machines and devices can be replaced by 3D printed parts. The use of high-performance 3D printing materials such as PEEK, ULTEM or PC allow to achieve elements that have very good mechanical properties. What is more, parts from these filaments can be chosen as metal parts replacement.

In case the supplier of our parts fails, we can produce the same parts ourselves without losing their properties. Contrary to general belief, we may have access to a wide range of materials that we can use in our business.

Imagine that you are missing a single part to complete the whole product. You don’t know when you’ll get the part you need. Although you have 99% of the elements, the lack of one of them delays your production. You can take the time to find a replacement from other suppliers. The choice of this option does not guarantee success, due to the fact that many companies closed down during the pandemic.

Having a 3D printer in your company can quickly help you to complete your product in case of such situation.

Replace your part with 3D printed element

Globalisation has led to the interdependence of countries and economies. Not only large corporations, but also smaller manufacturers rely on production centres in remote locations due to the fact, that this solution helps to minimize costs and increase profits.

The chief economist of EY, in an interview with Business Insider Poland, in the production of machinery, automotive industry, electrical equipment or computers, foreign components account for 40 percent. to ok. 2/3 of the production value.

Unfortunately, when the global supply chain is disrupted, it hits all economies, even 3D printing sector can be at risk. Many 3D printers producers don’t have their own plants in Europe, but they are depended on parts supplied from China. What is more, most of them have total production in Asia. But not 3DGence.

There may be a lot of crisis situation in the future that we can’t control. Is investing in a 3D printer a good idea? 3D printing technology may help you on various fields. You can produce from a small part, to holder for your complicated device to make it work to end-use part that is critical for your product.

3D printing can help you with many many different applications through many materials. If you have no idea what filaments will proper for your project, you can consult it with our 3D printing engineers: [email protected]