Become a leader in Your sector – grow your business faster by using 3D printing technology for industrial applications.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc a sodales nunc. Nunc luctus vehicula blandit. Sed in nulla mauris. Fusce eu dolor interdum, luctus tellus nec, mattis ex. In malesuada mauris eu diam vulputate feugiat. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos.

Safran

According to BCC Research global market for 3D printing in consumer goods manufacturing will reach $4.379 bln in 2024.

According to BCC Research 2019-2024 CAGR for 3D printing prototypes will be 21.5%.

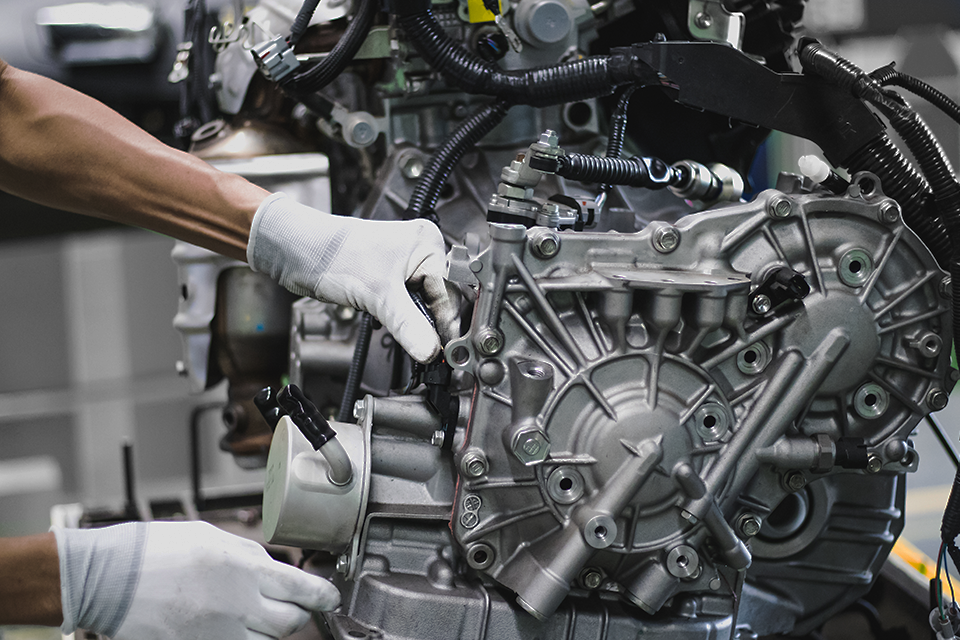

According to BMW, the customized 3D printed tools helped save 58 percent in overall costs. Troy Jensen, 3D printing: A model of the future, PiperJaffray, March 2013

According to BCC Research 2019-2024 CAGR for 3D printing in consumer goods manufacturing will be 20.7%.

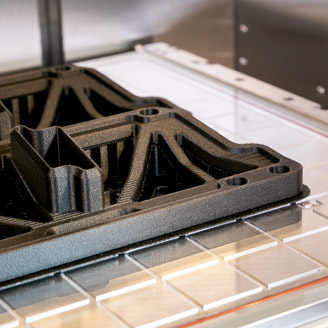

The perfect combination of 3DGence system elements for fulfilling the highest industrial standards.

The perfect combination of 3DGence system elements for fulfilling the highest industrial standards.

Benefit from best-in-class Total Cost of Ownership. Reduce the final cost of 3D printing at each stage of the production process. Each INDUSTRY line 3D printer is the part of the system that gives you the confidence of using tailor-made solution that helps you to save time and money.

For any company, costs are crucial and one of the asset of 3D printing is that it will help to bring costs down. The use of 3D printing technology help you to reduce tooling expenditure.

For any company, costs are crucial and one of the asset of 3D printing is that it will help to bring costs down. The use of 3D printing technology help you to reduce tooling expenditure.

For any company, costs are crucial and one of the asset of 3D printing is that it will help to bring costs down. The use of 3D printing technology help you to reduce tooling expenditure.