End-use parts

Case study

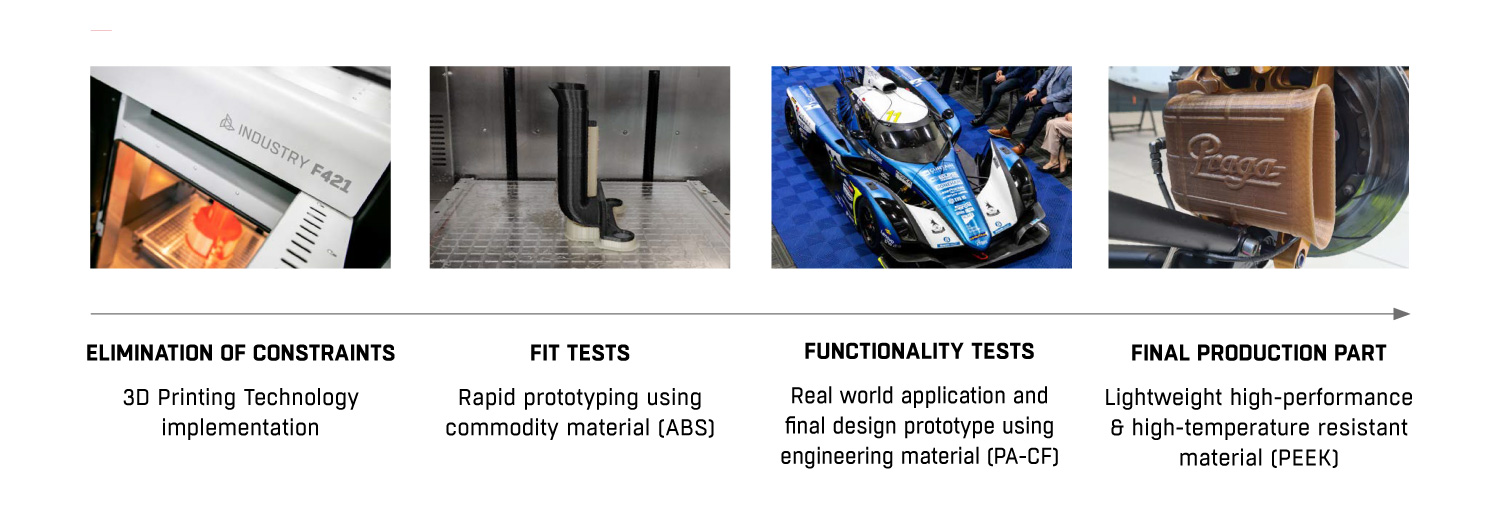

The aims of this project were: to manufacture concept brake duct components from in house designs to trial and ultimately track use. This component needed to not only function as a brake duct, allowing air to be directed towards the brake components, but also be manufactured to be lightweight and strong, easily removed quickly, and secure to function in harsh operating enviroments.

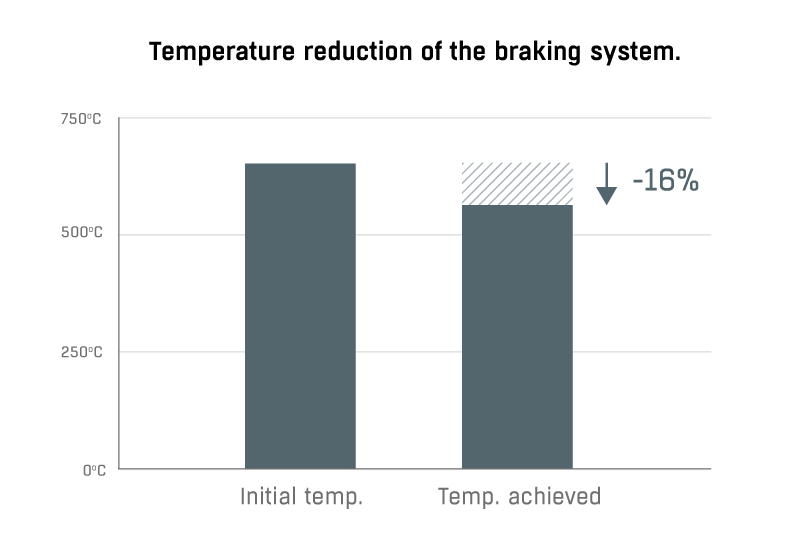

Brake sensitivity to temperature

Reduction in driving characteristics

Reduced and does not perform to the best of its ability

Following the success of the working prototype and considering the information gathered in operation, the design purpose and functionality were proven.

The next step was to produce a final product using an advanced end-use material – thus PEEK was chosen as it was appropriate for the application in terms of strength and temperature resistance.

Engineering creativity not limited by manufacturing technology

Easily applicable and tailored to your needs

trustworthy manufacturing technology

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.