INDUSTRY F1000

Engineered for industrial-grade performance, prioritizing precision, speed, user convenience, and safety throughout the entire 3D printing process.

This 3D printer is suitable for working with various technical materials, including high-performance thermoplastics and composites.

Large Build Volume

1000 x 600 x 800 mm

Printing Speed

3x times faster

Print

-BIG

-FAST

-SAFE

-COMPOSITE

Actively Heated Build Chamber

Achieve superior mechanical performance and unmatched print quality. Process advanced materials in a precisely controlled environment designed for optimal results.

Efficiency Redefined

Produce Parts at Unmatched Speed. The 3DGence unique 3-nozzle printing module accelerates production, delivering parts up to 3 times faster than ever before.

Composite materials

Robust Industrial Extrusion System Built for Highly Abrasive Composite Materials. Confidently print with carbon fiber-filled materials while minimizing wear and maximizing longevity.

Industrial quality and safety

Designed by Professionals, for Professionals: The 3DGence INDUSTRY F1000. Upgrade your production line with a reliable, durable 3D printer engineered to last and ensure operator safety at every step.

Technologies

Fully enclosed actively heated printing chamber

Fully enclosed actively heated printing chamber

Print engineering-grade and high-performance materials with unmatched precision, exceptional mechanical strength, and outstanding dimensional accuracy. High-performance filaments demand a stable printing process, combined with high extrusion and chamber temperatures, to ensure superior results.

Rapid infill printing system

Rapid infill printing system

Accelerate your production with the Rapid Infill Printing System. Designed to optimize material use and reduce print times, it delivers strong, lightweight structures without compromising quality or precision.

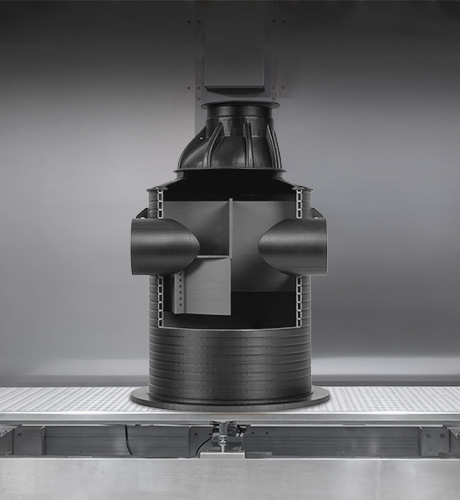

Composite ready design

Composite ready design

Advanced Feeding System tailored for composite materials, ensuring smooth, reliable operation and optimal performance with highly abrasive filaments.

Technical specifications

3DGENCE INDUSTRY F1000

Print technology

FFF

Build volume

1000 x 600 x 800 mm

Minimum layer height

50 µm

Number of printheads

3, printhead purging system

Filament diameter

1.75 mm

Printhead temperature

300°C (on basic version)

Model Materials

ABS, ABS-CF, PA, PA-CF

Support Materials

HIPS, ESM-10

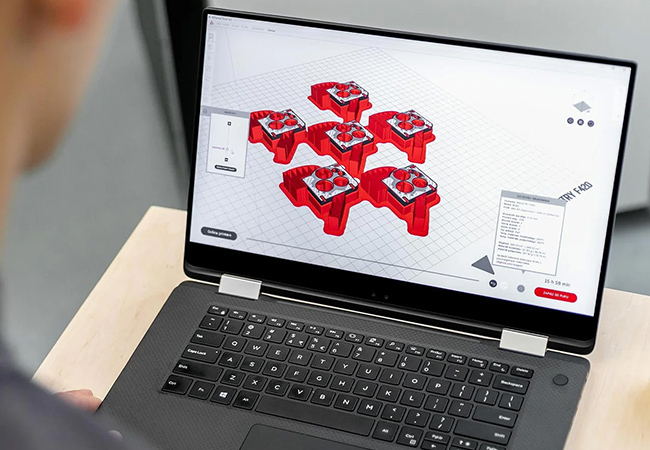

Software

3DGence SLICER 4.0

3D model slicing software is dedicated to 3DGence printers that allow file preparation and printing.

- Certified Materials Database

- Profile choice

- Large model split option

- Printing profile modification options

- Online options

3DGence CONNECT™

Engineered to meet the Industry 4.0 requirements, CONNECT™ links together the 3DGence ecosystem of hardware, software and materials to deliver end-to-end traceability of the additive manufacturing process.

- Remote control of the process

- Detailed data

- Permissions for the users

- Service access module

- Live camera feed

Contact

Want to know more?

Get in Touch with us!

Deutsch

Deutsch Polski

Polski Français

Français Americas

Americas