Many companies advertise their desktop 3D printers as “industrial”. Desktop printers may be used in actual industrial applications, but there are differences between 3D printers designed and built for true industrial applications and printers meant for hobby or professional use.

Sometimes an implied differentiation is based on price, with an arbitrary segmentation:

1. Desktop 3D printer for hobby or professional use, selling for less than $10,000;

2. Industrial 3D printers – selling for $20,000 or more.

Of course, each segment has a wide price variability – one can find a 3D printer for as little as $100 or above $300,000 – depending on the machine’s capability and complexity.

While price is an important factor, the real key differentiating factors are the specifications, performance, features, and functions offered by each 3D printer.

In this article, we will highlight our experience of the minimum specifications required to achieve true industrial 3D printing of engineering grade to highest performance material

An industrial 3D printer is a robust machine that has been designed and built to live on the factory floor, to advance and enhance conventional manufacturing

Here are a few features you should look for in industrial-grade 3D printers

A true industrial 3D printer should work with a suite of materials that are already used in industrial applications such as injection molding and composite part manufacturing. Such materials typically have robust mechanical properties or additional features such as chemical resistance, flame retardancy, or electrostatic dissipation. For instance, PAEK/PEEK polymers, ULTEM™, PC, or materials that are reinforced with carbon or glass fibers, are some of the materials that deliver superior performance for industrial or advanced applications.

What are the minimum requirements to process high performance and engineering grade materials?

The majority of high-performance materials have stringent requirements to be printed correctly. ULTEM™ 9085, for example, requires a temperature of at least 170 ⁰C in the build chamber to achieve optimum mechanical strength and accurate dimensions. Other materials need hardened drive gears, special build plates or dedicated nozzles.

This is why this feature alone is a strong indicator that the 3D printer can be considered true industrial, since it indicates the printer can work with materials already used in the industrial applications.

The heated chamber allows for the production of strong parts made with high-performance materials. However, there are major benefits even for entry level materials. For instance, parts printed of ABS in a passively heated build chamber are typically 20-30% weaker than the same material printed in an actively heated chamber. The difference in strength is even more pronounced in printers with enclosures only.

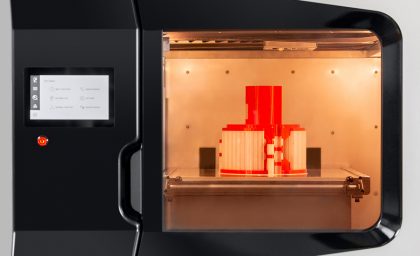

The dimensions of the build chamber are also key. The total X, Y, and Z volume will determine the largest part you can make, or how many parts you can print at once. The ability to maintain an elevated, stable, and uniform temperature in a large build chamber is one of the critical features of a true industrial 3D printer. The build chamber should use materials designed to work in a high-temperature environment.

A true industrial 3D printer should deliver parts quickly. When comparing the print speed of different 3D printers, one should evaluate the total time needed to print the same model with similar print parameters. This would allow a direct comparison of print speeds associated with similar print quality. It is also important to not confuse travel idle move speed with print speed. A high travel speed allows for fast nozzle switching and cleaning, which is important when printing with support material.

A higher print speed increases the productivity of the 3D printer, reducing the overall production costs and time to market.

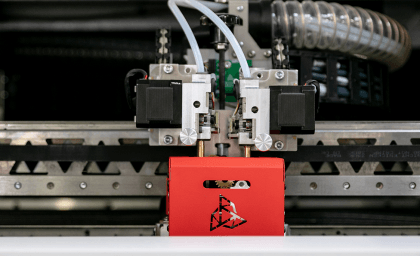

Printers featuring a single extruder nozzle use the same model material to build the support structures, also known as native support. In practice this means that the support is often more difficult to remove in post-processing, adding to the labor cost of producing a part. This can also limit design freedom, or increase the chance of damaging the part during post-processing.

Industrial 3D printers should feature a dual extrusion system, where one extruder is dedicated to the model material and the other processes the support material. When available, soluble support materials can greatly reduce labor costs and increase freedom of design, allowing the production of parts where removing breakaway or native support would be impractical. This also reduces total aggregate 3D part production time which is one of the main benefits of additive manufacturing.

Consult your project with 3D printing experts

Industrial 3D printers must withstand the rigors of the production environment and are designed for long-term use. Reliability is critical, and the printer should deliver a high print success rate with minimum downtime. The printer should be designed for minimal preventative maintenance and provide continuous operation for years, resulting in higher overall return on investment, and significantly reduced cost of ownership.

Industrial 3D printers are designed to produce high-quality prints with a high level of precision and dimensional accuracy, making them suitable for use in manufacturing applications. All thermoplastics have high coefficients of thermal expansion and will likely reduce in size from the printed state to the final part when cooled down to ambient temperature. However, industrial grade 3D printers and industrial grade 3D software are programmed to account for the shrinkage, delivering dimensionally accurate parts.

Industrial 3D printers can deliver repeatable and reproducible performance, time after time. While 3D printing is usually a sequential process, with parts produced one at a time, it is important to know that process variability is controlled, and part variability is minimized.

Repeatability refers to the capability of the 3D printer to produce parts within specifications, time after time – this is useful for series production. Reproducibility, on the other hand, refers to the capability of different 3D printers to deliver parts within specification – this is critical for print farms or print fleets where the machines may be at remote locations.

At the high extrusion temperatures required by thermoplastic materials, some of these may release gases with operator safety concerns, similar with other industrial production methods. Furthermore, the extrusion process itself may release microplastics, small particles that could be inhaled if released into the environment. This is especially likely with printers that do not have enclosed build chambers and air filtration technology.

For industrial operator safety, a 3D printer should therefore be equipped with a filter capable of removing the microplastics and material outgassing, such as a carbon or HEPA-H13 filter. A fully enclosed chamber enhances operator safety when paired with a filtration system.

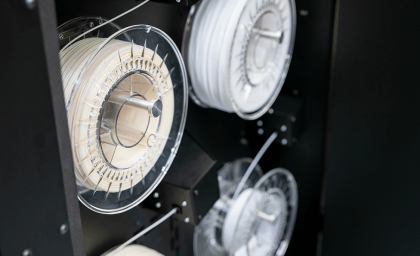

Additional useful features that provide operator safety, monitoring, and productivity are: an internal camera that shows the print progress, a cloud-based print management system that monitors the settings and print process, Wi-Fi capability, fully enclosed heated material chamber, nozzle cleaning station, automatic empty spool change, and more.

Many of these features are driving the development of automation and better overall performance in Industrial 3D printing.

As you would probably not buy a vehicle that works with only one brand of fuel, buying a 3D printer that locks you within a suite of overpriced, single-source materials will restrict productivity and flexibility, as well as considerably increase the ongoing cost of ownership.

A true industrial 3D printer should come with a certified set of open-market materials and engineered software profiles that meet your application needs – without the need or knowledge to modify expert settings to obtain print success and repeatable results.

Additionally, the flexibility to use 3rd party materials when needed enhances the utility of the 3D printer. 3DGence hardware and software offer the flexibility to expand material use, and utilize custom settings for custom applications.

The price of the 3D printer is always important, but equipment that does not fully meet your needs is too expensive (time, productivity, labor cost) regardless of its price.

This is why you should carefully compare the available options and select the 3D printer that provides you with the most value in features and performance at an accessible price.

3DGence provides the best total value in industrial FFF technology for most applications.

1.Contact the OEM manufacturer and ask for:

2. Verify the information

3. Request for a 3D printed sample model

How to choose a sample model?

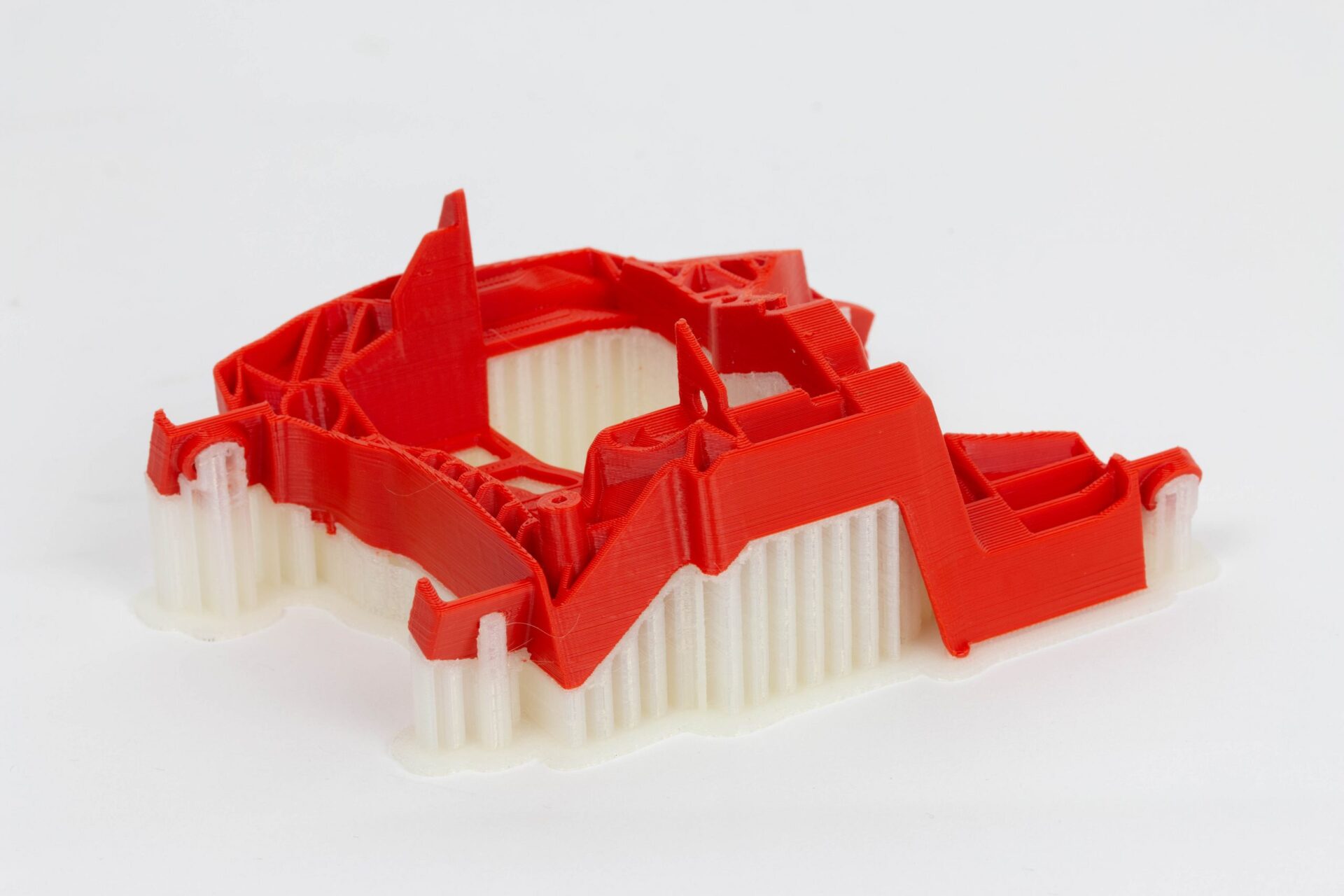

Choosing a sample model should be easy and straightforward. The model should either be something that you would look to print yourself, or a complex part to determine the capability of the 3D printer.

Below you can download our sample print that you may find useful:

In this model you can find:

This 3D printer was created based on the feedback from our industrial customers. It offers all the features that you expect in a true industrial 3D printer – high-performance materials, interchangeable printing modules, cloud management system and much more. It offers the best price to print volume (360x380x420 mm) ratio on the market, with an actively heated build chamber reaching 195 ºC.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.