Most printing materials are highly hygroscopic, which means that they easily absorb ambient moisture. Even tight factory-packaged filament is not always suitable for use when removed out of the box. We should bear in mind that the purchase of the material itself is not the last step before printing.

For the 3D printing process to run properly, it is essential to prepare the filament properly. Filament drying at the appropriate temperature eliminates moisture that the filament could have absorbed.

Hygroscopicity, or filament susceptibility to absorb moisture, is an undesirable phenomenon in this case, but it occurs very often, especially among engineering materials. How does it look in practice? Water settles on the outer material layers and penetrates inwards having a direct impact on the 3D printing process and models.

The hygroscopicity filaments causes significant problems during the printing process itself, not always visible at first glance. Even a small amount of moisture in the material can have an adverse effect on:

Get the 3D printed parts you need just in time

The key to obtaining the desired properties of a printed part is proper filament drying before printing. What does this process consist in?

To remove excess moisture from material, it is necessary to place a filament spool in a suitable device to dry it. The time and temperature at which the heating operation should be carried out depends on the material used.

Most engineering materials should be heated before printing to get rid of the moisture absorbed by 3d printing filament from the environment. In appropriate annealing conditions, we will observe the evaporation of moisture from material. Be careful when selecting the temperature, too high a temperature can deform filament. It is recommended to follow manufacturer’s guidelines.

Check the recommendations for some engineering materials for heating them after removing them out of the box.

Proper preparation of materials is necessary for the proper printing process. There are several ways of filament drying.

There are many devices on the market that are dedicated to drying materials.

At 3DGence, we use a professional Drying Oven SLW 53 laboratory dryer or Material Management System to heat materials before use.

3DGence Material Management System ensures each material will be properly dried, and moisture-controlled according to material specification. What’s more entire workflow from material selection, configuration, compartment assignment, rediness is streamlined and intuitive. Watch the video on how to dry filaments with MMS or find out how to get Material Management System 30% off

Get the 3D printed parts you need just in time

Yes, even if we heat up the filament before printing, during the process itself, which often lasts long, the filament can absorb ambient moisture again, if it is not properly protected. That is why, to print from engineering materials with high hygroscopic properties, we should use industrial 3D printers equipped with a heated filament chamber. A heated filament chamber maintains a high temperature and restricts access of printer’s ambient air, thus preventing material from absorbing moisture again.

According to the recommendations, ULTEM filament should be heated for 12 hours at a temperature of 120⁰C. For of this test we checked what happens to the print if we do not dry this material before the printing process. We placed unheated ULTEM in the heated filament chamber of the 3DGence INDUSTRY F421 printer and started printing.

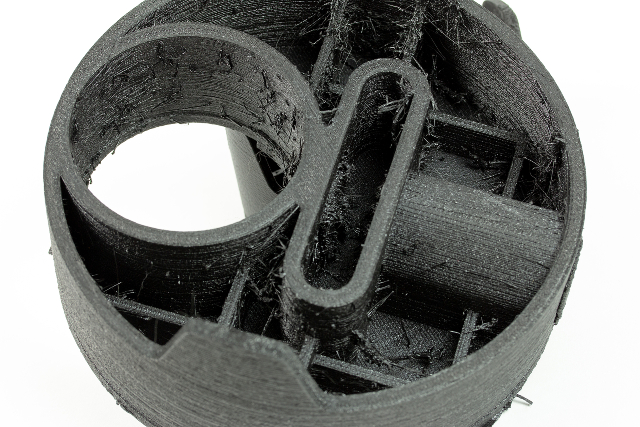

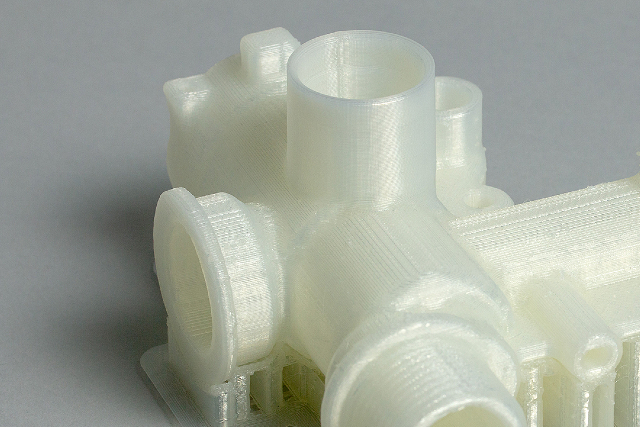

We can see that over time, the heated chamber in the 3DGence INDUSTRY F421 printer helped to evaporate moisture from the outer coils of the material. This had a significant impact on the quality of the model, which improved with the gradual removal of water from the filament. The porosity of the printed sample also decreased over time.

Tight factory packaging does not guarantee that our material has not absorbed moisture and that it will be suitable for printing without prior preparation. Although there are no visible visual differences, only the weight measurement and the appearance of the print itself can indicate that the material has absorbed some water.

If our filament is not prepared well, during extrusion from the nozzle, we can:

The consequence is a loss of extruded material used to make the layer and pores embedded in the printout structure, which weakens the printed item.

The filament weight in the package may be close to the weight of the material left in a humid environment, indicating that the filament manufacturer does not always provide appropriate conditions during packaging.

After unpacking, the weight of the Nylon 680 [Taulman] filament was 466.5 g (after subtracting the weight of the spool). The material was left for 24 hours under average temperature conditions of 23°C and air humidity of 48%. Has the material absorbed ambient moisture? Yes, after weighing the material, it turned out that its weight increased by 0.6 g to 467.1 g. Preprocessing before printing proved necessary. The material was heated in accordance with the recommendations and placed for 8 hours in a heated printing chamber at a temperature of 70°C in the 3DGence INDUSTRY F340 machine. Heating the material reduced its mass to 464.2 g. This means that the heating process removed moisture from the filament weighing 2.9 g, which is 0.62% of the filament, as before heating.

Industrial 3D printer can be a complementary machine that supports traditional manufacturing processes. Choosing a proper machine that will suit your needs is not an easy task.

If you would like to know more what industrial 3D printer will be proper for your company, you can consult with 3D printing experts: [email protected]

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.