Maximize Output and Return on Investment

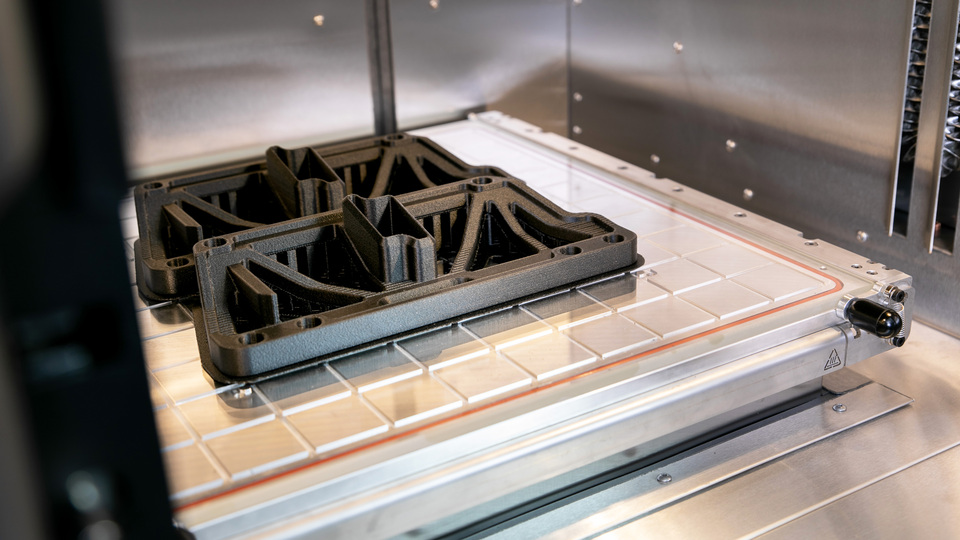

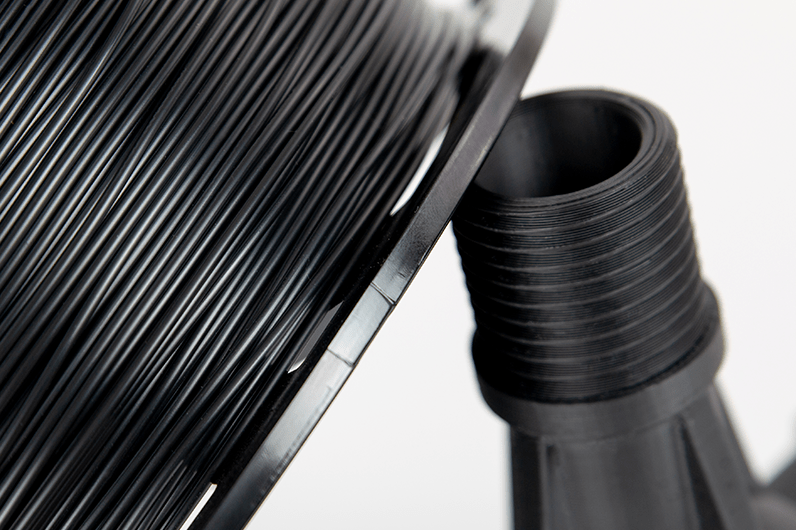

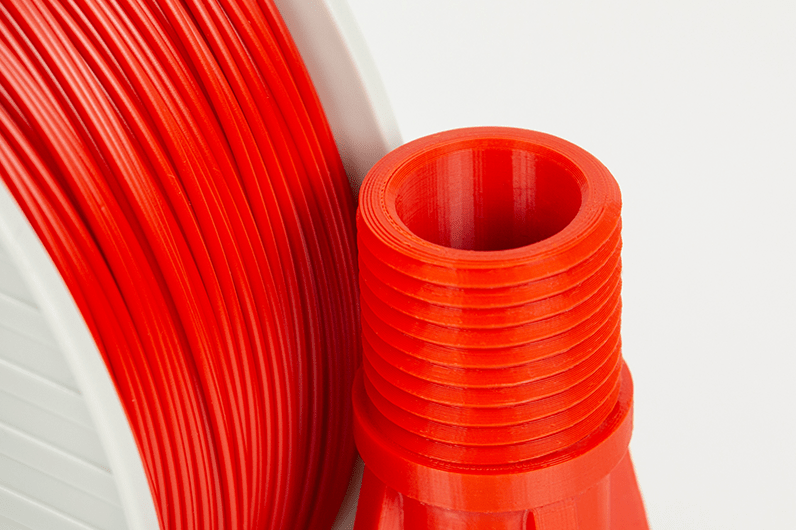

Advance to true industrial grade 3D Printing with the 3DGence INDUSTRY F350 Rapid 3D printer. Designed for engineering grade and composite materials (CF-PA, CF-PC, GF-PC), fully compatible with high-temperature polymers (PEEK, PEKK, AM™200), the INDUSTRY F350 system future proofs your investment and scalability

INDUSTRY F350 provides high-speed, repeatability, reproducibility, and reliability to enhance your 3D printing capabilities – from R&D to flexible production

Produce true engineering grade end-use parts at an accessible value without compromising industrial performance, connectivity, or build quality

Autocalibration

Autocalibration

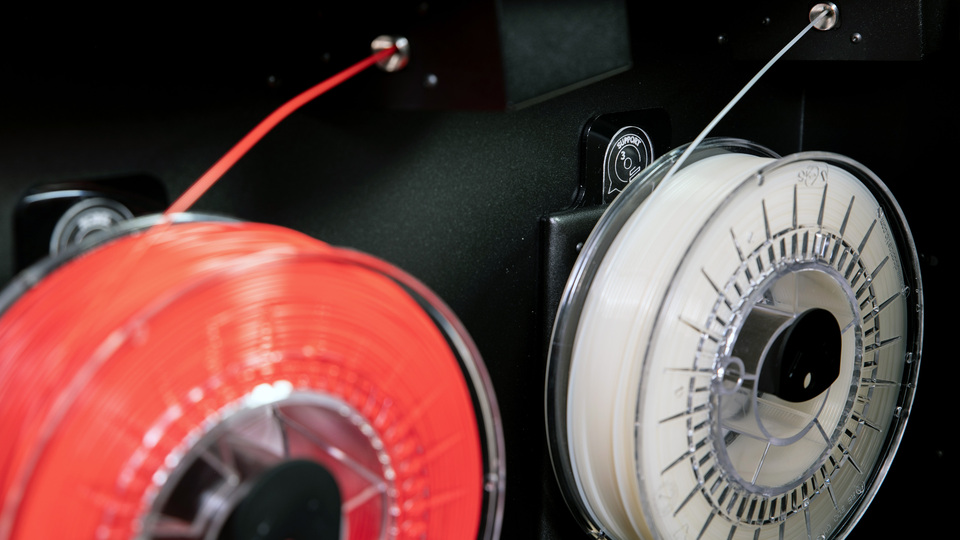

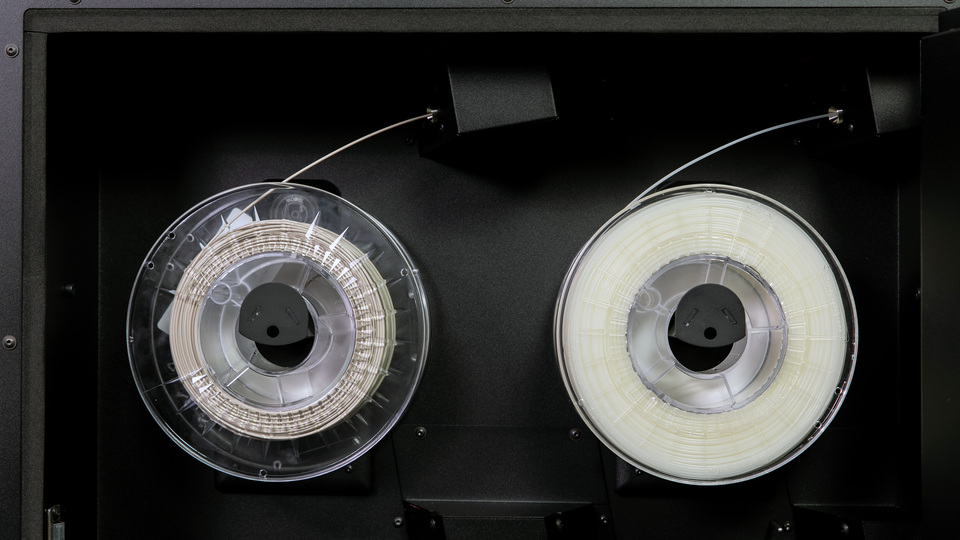

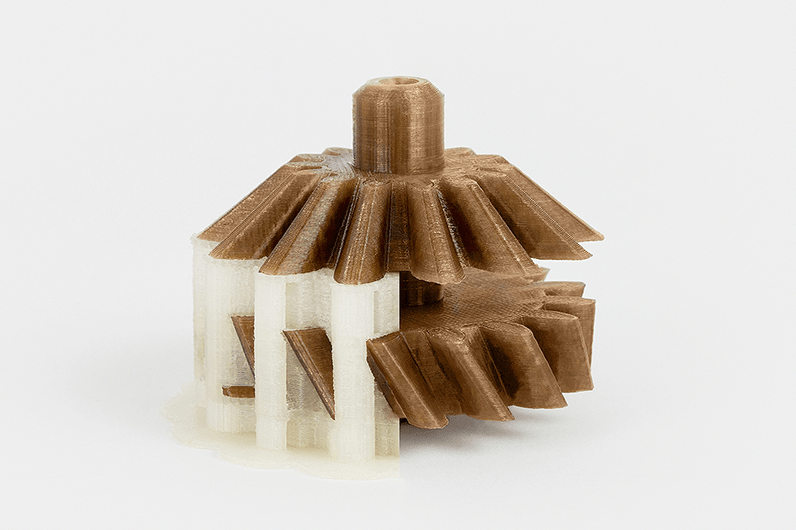

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.