It is enough to reduce the aircraft weight by one kilogram to cut down on its carbon dioxide production by 25 tons throughout its lifetime. Producers are seeking lighter and more durable materials. This is where 3D print can be of great help – its benefits have already been appreciated by such big corporations as Airbus and Boeing.

In 2014 Airbus started tests on titanium components made with this technology and since 2017 they have been used in serial aircraft. The cabins of Airbus A320 flying for Finnair are provided with 3D printed components visible for passengers – they are panels which fill the gaps in the rows of overhead lockers.

Since 1997 Boeing has been carrying out research and development on using additive technology for aircraft production. Nowadays the company has a collection of over 60,000 printed parts. They can be found both in commercial and military aircraft.

3D printed components are by about 55% lighter than those produced with traditional methogs. Lighter means more economical? Additive technology has been attracting attention of the global aerospace giants for many years now. They also allow the reduction of material consumption by as much as 90%.

Big corporations and small enterprises in the sector make 3D printed aircraft and helicopter parts, as well as lighter and more efficient engines and turbines. Due to safety reasons the 3D technology has been used for making of non-critical parts which are not subject to the heaviest overloads. The technology serves production of brackets/supports of aircraft systems but also visible parts of cabins. Boeing has been testing making of bigger structures, e.g. parts of wings.

We will help you to accelerate your project

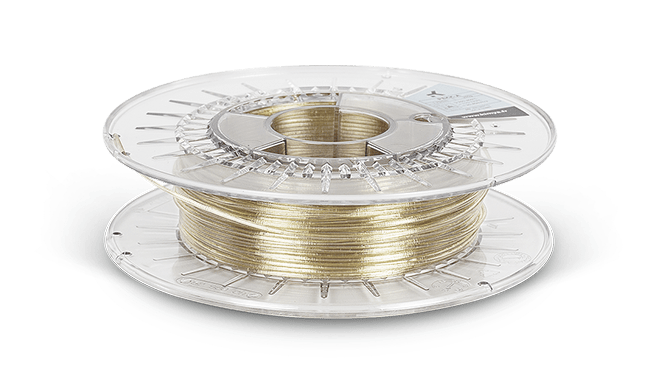

There is no doubt that besides the weight of parts which contribute to the aircraft weight and hence fuel consumption and CO2 emission to the atmosphere, robust materials able to sustain heavy loads and ensuring safety play a very important role in aerospace. That is why initially producers used to print mainly plastic parts on 3D printers. However filaments have been gradually improved with the development of the 3D technology. Materials reinforced with glass or carbon fibres can now be used for production, which means new implementation areas for 3D printed components in aircraft.

Airbus has introduced new materials into its planes. The company installed a 3D printed titanium bracket for the first time in serial production of A350 XWB. The bracket is a part of a pylon which connects the wings with the engines. Some Airbus A320neo and A350 XWB test planes use 3D printed metal brackets and venting pipes.

ULTEM™ resin is one of the only 3D printing plastics certified for aircraft components. In this industry, most elements are required to have low flammability and toxicity. That’s why ULTEM is a perfect material for aircraft industry. It is characterized primarily by flammability class V0 according to UL94 standard, and has good FST (Flame, Smoke, Toxicity) properties. What is more, this material reflects high mechanical and thermal resistance. Due to that it fits any use requiring high resistance to heat and chemicals

ULTEM™ has been more and more frequently replacing metal and heat-curing plastics. It is used mainly in the manufacturing of electric and lighting systems, e.g. in headlamps, ignition or engine elements, electric switches, frames and bulb sockets. A component in an existing aircraft model can be easily replaced with a lighter 3D printed version.

According to the forecasts in the recently published results of studies carried out by Research and Markets, the 3D print market in aerospace will grow by 23.01% until 2021. The industry has already been using additive technology successfully, while aerospace giants declare that there will be more areas for 3D print breakthrough implementation in their sector.

According to the forecasts in the recently published results of studies carried out by Research and Markets, the 3D print market in aerospace will grow by 23.01% until 2021. The industry has already been using additive technology successfully, while aerospace giants declare that there will be more areas for 3D print breakthrough implementation in their sector.

3D printing can help you with many many different applications through many materials. If you have no idea what filaments will proper for your project, you can consult it with our 3D printing engineers: [email protected]

MB Aerospace Poland specialises in technologically advanced heat and surface treatment for the aerospace sector. It launches new products and makes parts for aircraft engines production.

With regard to the needs of the aircraft sector components made of aluminium, stainless steel or superalloys based on nickel and titanium have to be highly accurate. 3D printing technology has been implemented on some stages of their production. What is more owing to 3D printer allow to test new solutions..

The production of special accessories for fixing parts to CNC machines is time- and money-consuming. Owing to 3DGence printer MB Aerospace makes e.g. compression sleeves used for turning tools to fix an aircraft part during processing. The solution brings significant savings.

MB Aerospace from Rzeszów has used 3D print to make marking tools from PLA filament. A prototype printed in FDM technology helped to produce a finished item protecting a part from damage – it eliminates vibration during treatment.

The price of a similar steel item amounts to ca. 520 EUR while the printed one costs about 2,50 EUR.