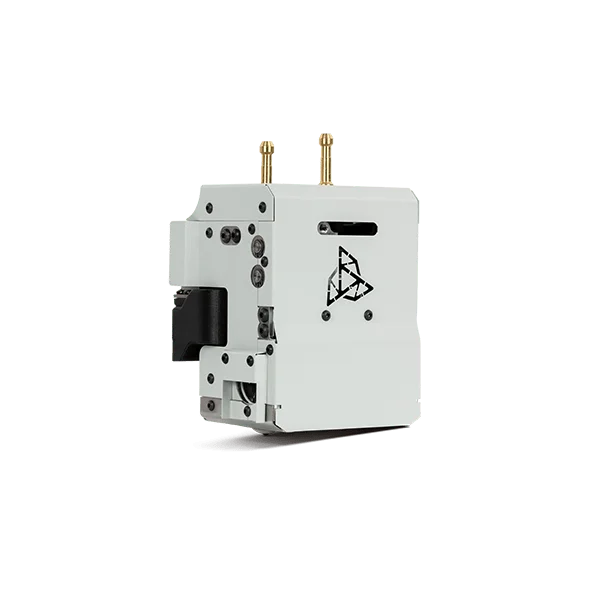

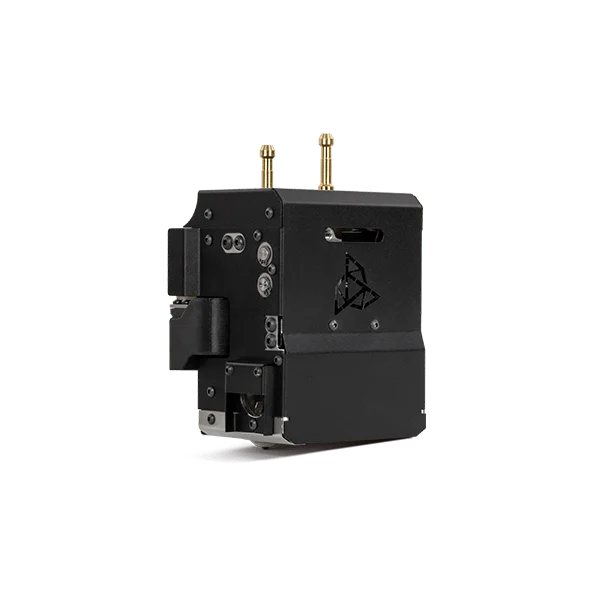

Modular system used in the 3DGence INDUSTRY F421 and INDUSTRY F350 is a practical and cost-effective solution. 3DGence modular system is unique in the industrial 3D printers segment. The possibility of using three different modules in one 3D printer allows you to produce repeatable models from the widest range of filaments. Each module is customised to a specific group of materials in order to optimize the printing process. Internal modules memory saves the time that would be used for calibration. All the modules are also equipped with dual hotends and inactive nozzle lifting system.

Basic printing module dedicated for 3DGence INDUSTRY F421 and INDUSTRY F350, that allows to print the commodity materials. M280 module is also capable of printing soluble support structures from ESM-10.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

M360 is a high temperature module that enables INDUSTRY F421 user to print the models of ULTEM™ – high performance polymer of very good mechanical properties and capable of withstanding high temperatures. M360 can print also engineering grade materials, such as PC.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

M500+ is one of the interchangable modules that can reach up to 500C of extrusion temperature. Such high temperature combined with the printer’s heated chamber allows to print high performance polymers like PEEK or PEKK on INDUSTRY F421. On M500+ module can print PEEK and PEKK on the soluble ESM-10 support.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

Up to 280°C

Up to 360°C

Up to 500°C

0,5 / 0,5 mm

0,4 / 0,4 mm

0,4 / 0,4 mm

ABS, ABS Carbon, Addigy® F1030 CF10,

ASA,

PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS, PC-CF, PC-ESD, PEKK Carbon, ULTEM™ 9085

PEEK, PEEK AERO, PEEK-CF, PEKK-A, Victrex AM™200

ABS, ABS Carbon, Addigy® F1030 CF10,

ASA, PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS FR, PC-ESD

PEEK, PEEK-CF,

Victrex AM™200

HIPS (breakaway)

ESM-10 (soluble)

ESM-10 (soluble)

ESM-30 (soluble)

ESM-10 (soluble)

ESM-30 (soluble)

| Print Temperature | 340 – 500°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PEEK, PEKK |

| Support Materials | Dedicated breakaway ESM-10 (soluble) |

| Print Temperature | 265 – 340°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PC, PC-CF, PC-ABS, PC-ESD |

| Support Materials | Dedicated breakaway (ABS) |

| Print Temperature | 190 – 265°C |

|---|---|

| Nozzle Diameter | 0,6 / 0,6 mm |

| Model Materials | ABS, ASA, PP, PA-CF |

| Support Materials | HIPS (breakaway) ESM-10 (soluble) |

| Print Temperature | 190 - 265°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | ABS, PLA, PP, ASA, PA, TPU |

| Support Materials | BVOH (water soluble) HIPS (breakaway) ESM-10 (soluble) |