Case study

The AGH Racing team faced the task of designing and building a functional steering prototype for a race car. In doing so, it was necessary to take into account the cost, timing, and technological limitations of conventional manufacturing methods, significanthly affecting the full feasibility of the steering concept of the car under construction.

Usually, the knuckles are being made of aluminum by milling. The introduction of significant changes in the geometry of the part makes it impossible for such a complex shape to be subjected to conventional machining. In order to verify the project, without big financial investment, FDM technology was chosen.

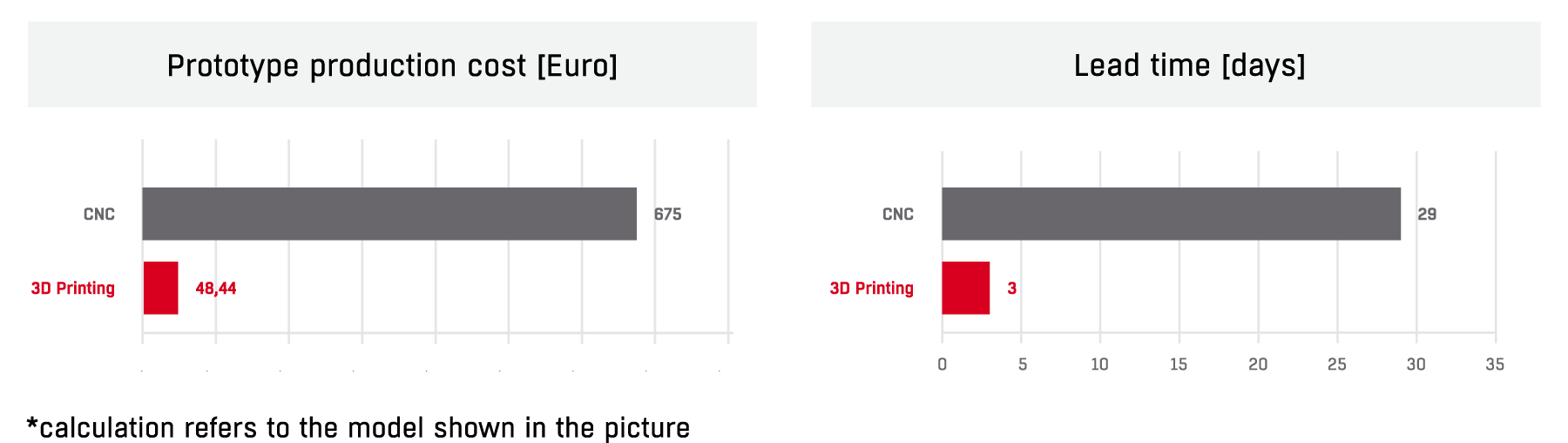

The 3D printed steering knuckle helped to verify the project’s assumptions before forming the model itself and avoid costly improvements in other technology (printing in SLS technology reached up to 20,000 €).

Due to the FSAE race in Michigan, AGH Racing had to make a prototype of the new model of steering knuckle in a very short time. 3D printing in FDM technology allowed to receive a prototype much faster. The use of soluble ESM-10 solution as a support material allowed for efficient post-processing of the model. SLS prototyping would take too long.

Thanks to the 3DGence INDUSTRY F340 a prototype was 3D printed in less than 2 days. This time reduction allowed students to present new details to the judges.

86%

92%

90%