Case study

Due to the shortage of PPE caused by the sudden and wide-spread SARS-CoV-2 coronavirus pandemic, many medical and health personnel including hospital, clinic and first responders are increasingly at risk of exposure to this highly contagious disease. Restrictions and shortages on domestic and foreign supplies, as well general disruption in the supply chain, left medical facilities and staff without basic required safety measures. 3D printing is perhaps the fastest way to address this sudden shortage and quickly retrofit health centres with the missing PPE face shields and other vital PPE equipment.

3DGence utilized FFF 3D printing technology, skilled R&D and Production teams, and material expertise to quickly develop a protective face shield design of which thousands per week can be produced in rapid succession. Full-cycle implementation, from project concept, sourcing required materials and components, to final production in the 3DGence Rapid Production Center.

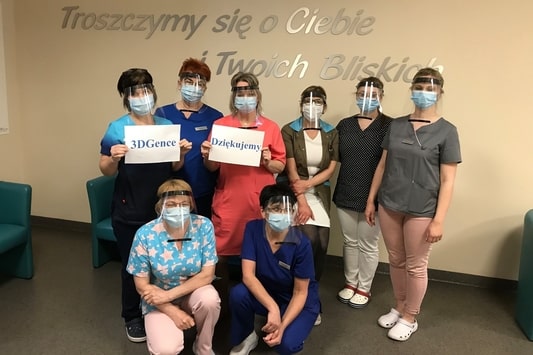

On behalf of our health care colleagues, thank you very much for your support. Medical facilities lack basic medical equipment, 3D printing is a chance for all of us to equip hospitals with needed shields. Thank you 3DGence!

Paramedics stand on the front line. That is why it is so important to ensure the safety of those, who save our health and lives. Thank you 3DGence for delivering face protective shields in such a short time!

We thank our donors for their help, support and great heart. There are no words to express our appreciation.

3DGence responds to the needs of the market, providing their line of as many as fifty-two 3D printers. Such a choice of devices guarantees a short lead time of individual elements or even small- and medium-sized production series. All the inquiries about 3D services are forwarded to a specialised team of application engineers who help select the proper materials to the respective needs.

Check 3D Services for your company