Case study

PANOVA operates in architectural design, urban planning and investment support in the field of design and construction.

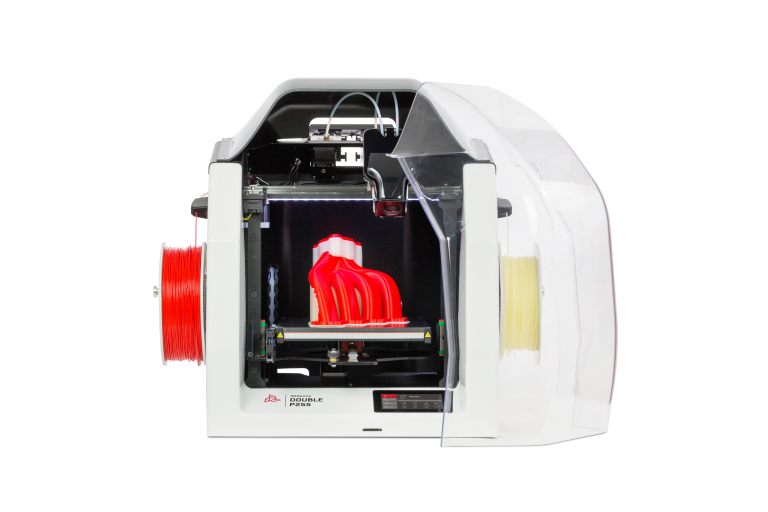

Based on historical materials (maps and photos), PANOVA use the 3D printers to create spatial architectural models of buildings to reduce costs and time of the schematic design stage characterised by significant dynamics of changes. The 3D printing technology also gives the company option of detailed determination of the size of a building and makes it easier to detect any design errors. What is important, it also enables them to physically check the conceptual assumptions for the building and its site development.

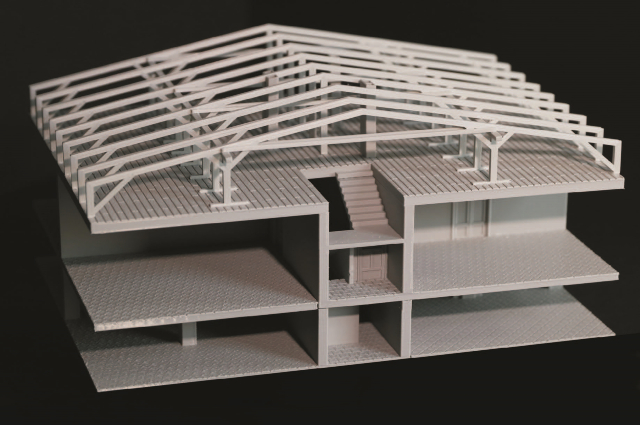

Execution of the building model based on archival materials from 1897 in 1:75 scale using 3D printing technology to present the concept of building revitalization.

Manually making mock-ups is very time-consuming and it requires tedious work of modelers when outlining elements, their precise cutting, gluing and painting. The use of 3D printers in the company decreases the time needed to complete the mock-up of the building by 77%. Support of external companies was not necessary.

The concept phase is often associated with high dynamics of changes in the project, and the same visualizations do not always reflect the spatial nature of the object. The model makes it possible to present the investment in an understandable way. 3D printing enabled a quick response to changes made by the investor-the possibility of producing subsequent iterations of the project in various development options.

In the process of revitalization of objects, it is important to show their original appearance, which could be lost as a result of the reconstruction. The key is to get accurate details such as door ornaments. Execution of precise elements, even those with advanced geometry, was possible to an accuracy of up to 0.1 mm.