DOUBLE P255

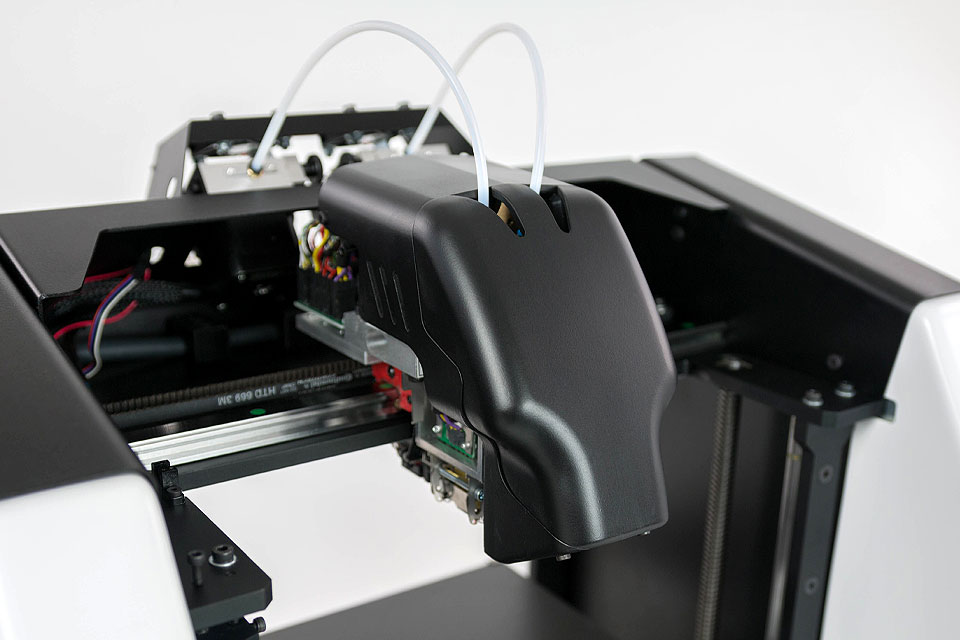

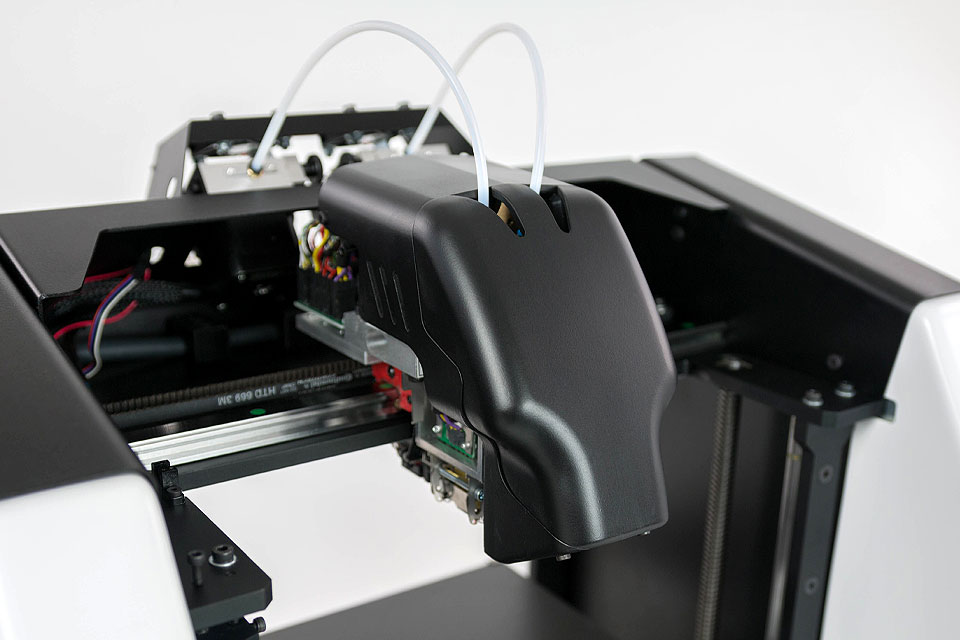

Dual-extruder 3D printer developed for professional use certified by TÜV Rheinland. Designed to create accurate parts with great detail using soluble support material.

Dual-extruder 3D printer developed for professional use certified by TÜV Rheinland. Designed to create accurate parts with great detail using soluble support material.

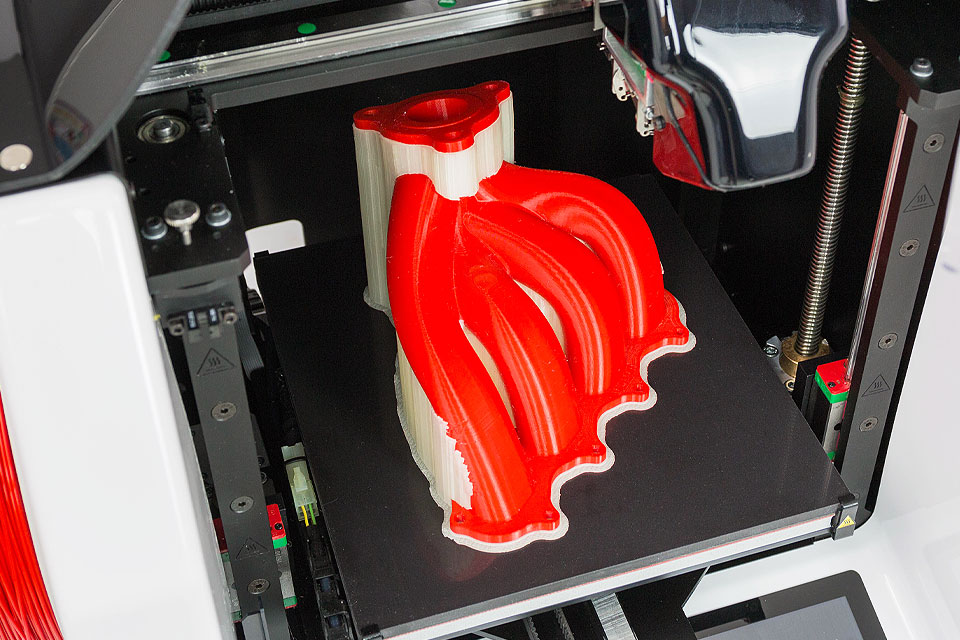

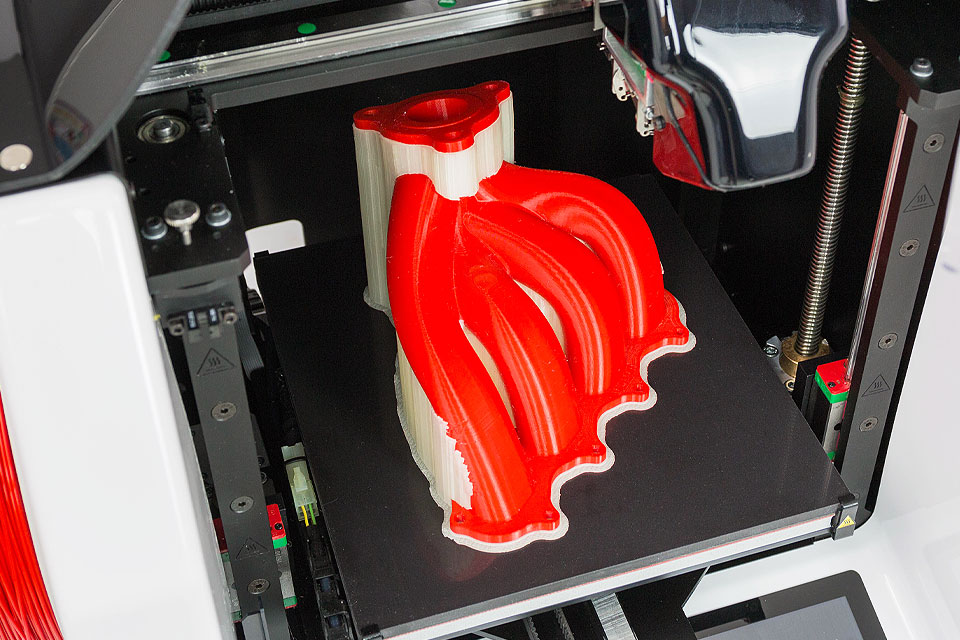

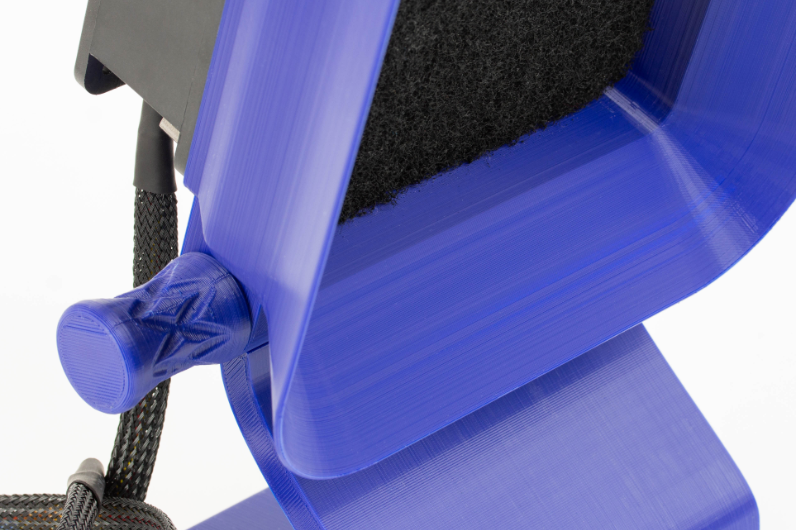

3D printing geometrically complex models

Remove supports from the 3D printed parts without any problems. Obtain elements with a certain mobility by rinsing filament in water.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

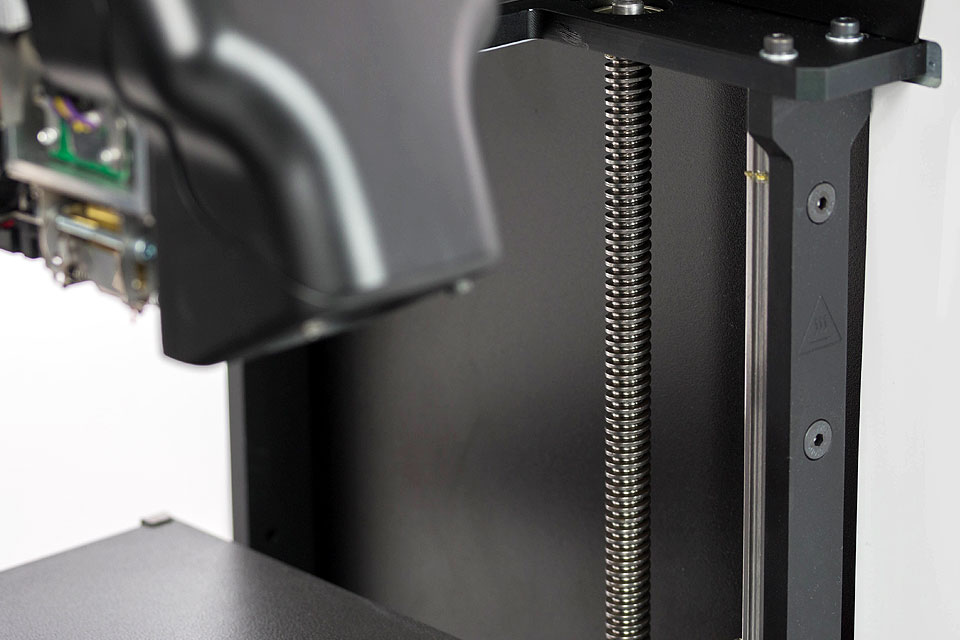

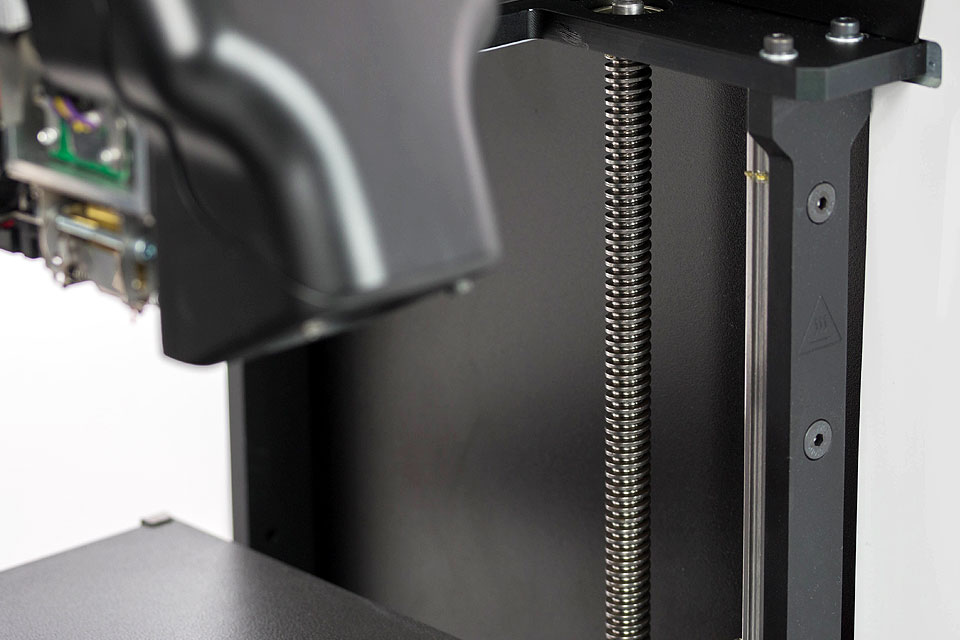

No need to calibrate the 3D printer manually

User involvement in the calibration process has been minimized as much as possible.

Due to special sensors, the 3D printer scans the heatbed and stores the map of points, the device detects any surface irregularities. The measurement of the height of the head above the heatbed is done automatically.

This solution provides a significant increase in quality and eliminates the problem with adhesion between printouts and the surface.

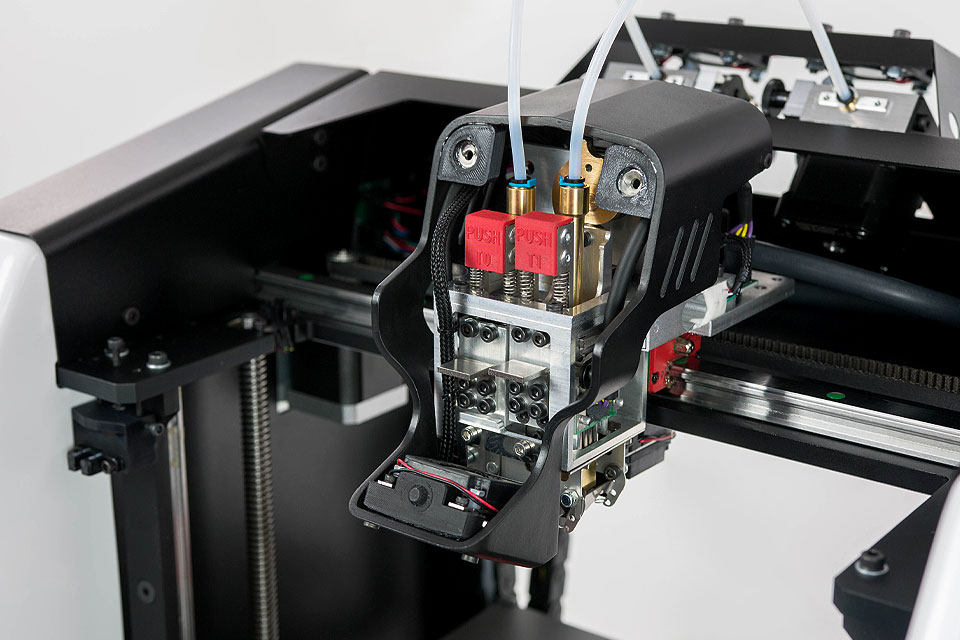

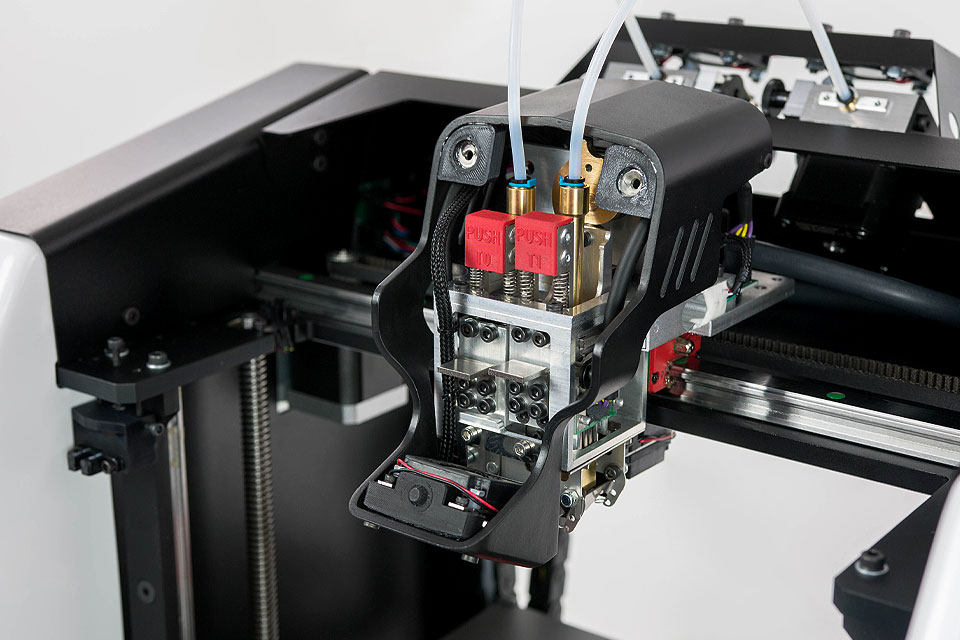

3D printing with multi-materials is possible.

The use of proprietary hotends guarantee high-quality parts 3D printed from model and support material. In addition you can swapped out hotend quickly without requiring any tools

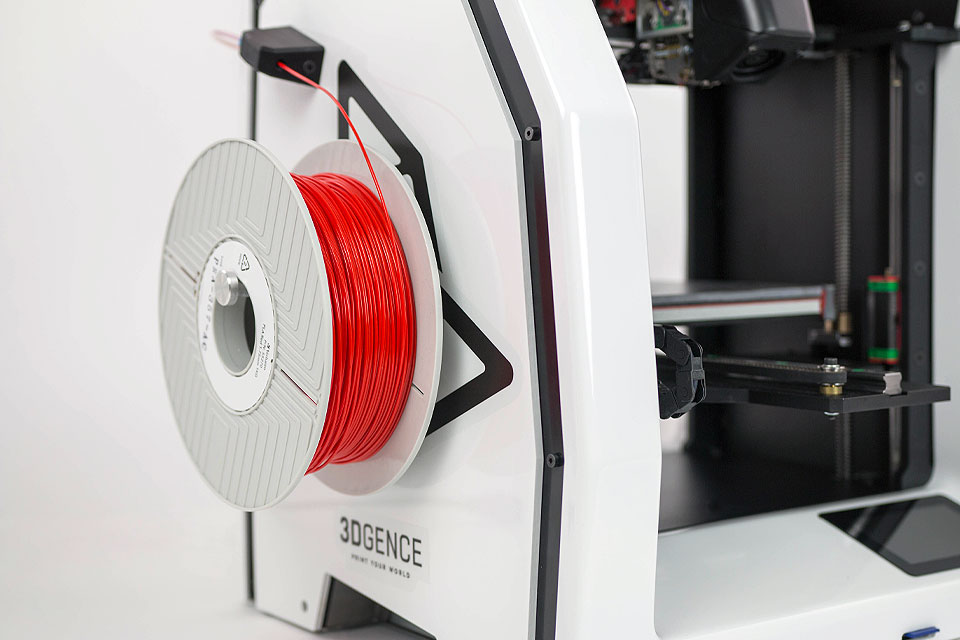

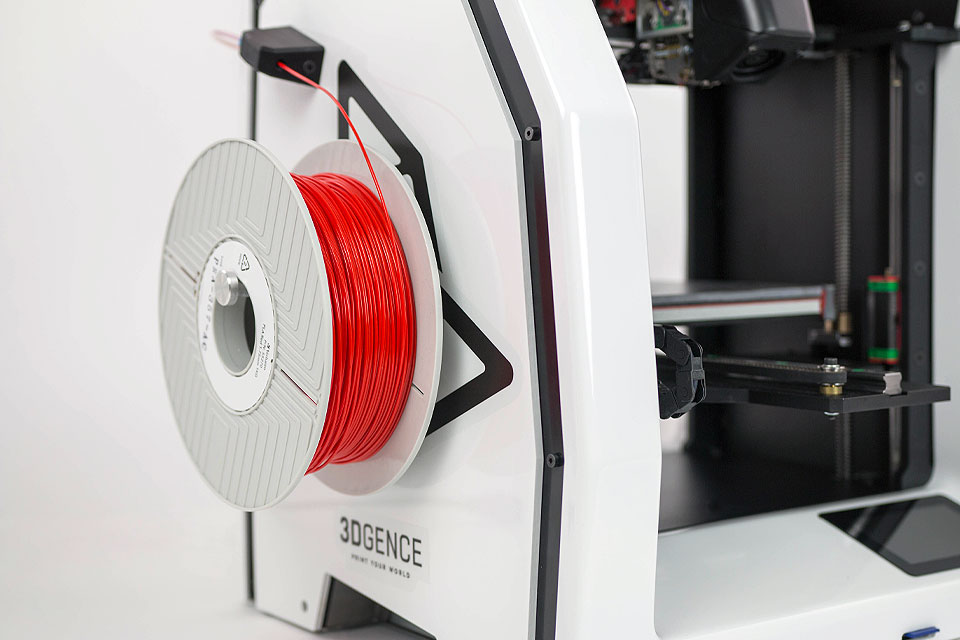

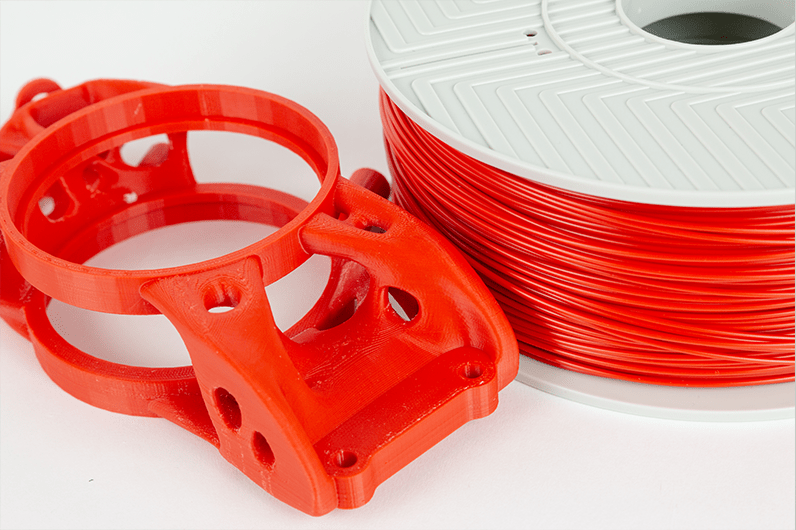

Working with all the primary materials used in FDM

3D print with all filaments available on the market, you are not restricted to a specific brand of filament.

R&D deparment who dedicate a significant amount of time to testing materials requested by customers and developing material profiles that extend the range of printing options available.

Ensuring stable temperature during the printing process

Improve the quality and dimensional accuracy of the printed parts and use dedicated enclosure to reach steady temperature during 3D printing with the Smart ABS, PP and PolyMide CoPa

The extrusion quality measurement system is equipped with automatic error detection, which enables constant supervision over the quality of each printout.

3DGence DOUBLE P255 will automatically pause the printout if there will be a shortage of material in the feeding system.

The extrusion quality measurement system is equipped with automatic error detection, which enables constant supervision over the quality of each printout. 3DGence DOUBLE P255 will automatically pause the printout if there will be a shortage of material in the feeding system.

3D printing is increasingly used in medicine and allows for detailed planning of operations. This makes it possible to select the appropriate operating technique, discuss it in the team and shorten the time of the procedure itself.

The use of 3DGence INDUSTRY F340 allowed verifying the vacuum manifold, which is one of the elements creating a hydraulic system of a pump compartment inside fire engines.

In the process of revitalization, it is important to present the building’s body with a high detail referring to the original design. PANOVA created the complex building model based on archival materials from 1897 in 1:75 scale using 3D printing technology.

Electric auto-revolution can be supported by 3D printing technology! Using 3D printer AGH Racing could test original design of steering knuckle at a very low cost and in just two days.

Offers excellent print quality, high fatigue, mechanical strength and good thermal resistance.

Print technology

FFF

Build volume

190 × 255 × 195 mm (9 448 cm3)

Min. layer height

20 μm

Number of printheads

2

Nozzle diameter

0.4/0.4 mm

Filament diameter

1.75 mm

Printhead temperature

270°C

Buildplate temperature

160°C

Model materials

PLA, PP, PA, ABS, TPU

Support materials

Water-soluble support material BVOH, HIPS

Power requirements

230V AC

Max power draw

600W

Communication

USB drive, SD card

Slicing software

3DGence SLICER 4.0

Sensors

Material flow control sensors

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.