HIPS is a polystyrene-based polymer similar to ABS but its mechanical properties and general resilience are slightly higher.

The model surface hardness is high which leads to improved scratch and impact resistance. Its properties allow HIPS to be used as model material but also as a support for different materials. HIPS is easy to paint and it’s machinable. It’s non-toxic thus safe for contact with food, non-biodegradable but recyclable. As the support material is can be easily removed without the need for any further post-processing and providing high dimensional accuracy and high surface quality. HIPS is soluble in D-Limonene which allows us to use it as the support material for complex and demanding prints. HIPS works very well with the ABS.

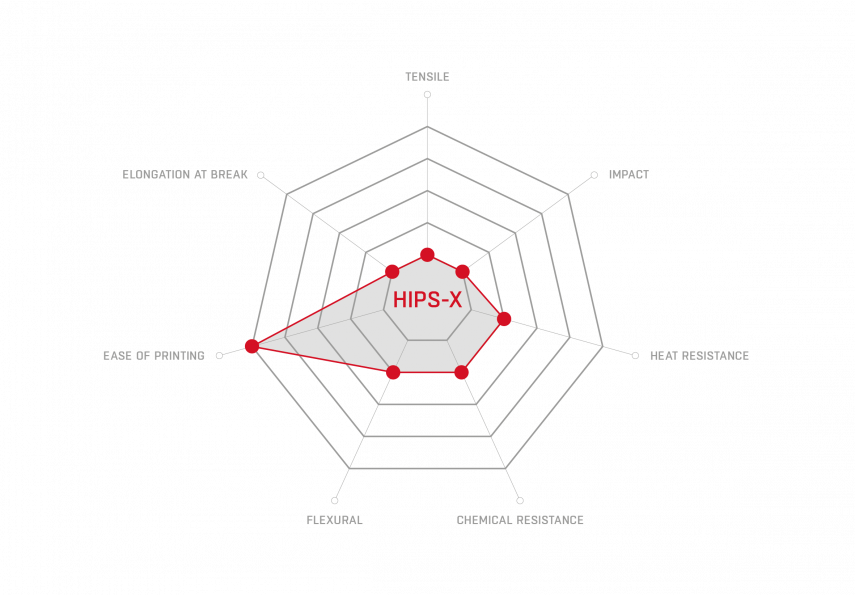

3DGence recommends using modifed version of this material called HIPS-X. This material is used only as support material and has better resistance for higher temperatures.

Low volume production

Additive manufacturing is frequently more cost-effective than other legacy manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time tp market.

End Use Parts

In many instances the mechanical properties and surface characteristics of 3D printed parts meet and exceed the customer’s expectation, allowing their use in the actual product.

Prior to launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components, accelerating the iterative development cycle and time to market.

We will help you to choose the right material