ULTEM™ (PEI)

ULTEM™ is a high-performance polymer that is widely utilized in the most demanding market segments that include aerospace, automotive and medical industry.

ULTEM™ is a high-performance polymer that is widely utilized in the most demanding market segments that include aerospace, automotive and medical industry.

ULTEM™ due to unique material properties like low flammability and toxicity is highly appreciated and approved by the aircraft manufacturers and railroad industry.

In order to obtain high print quality, it is necessary to run the printing process in a heated chamber. The minimum temperature has to be 170°C, and the warmth has to be evenly distributed. Printing with this material also requires a dedicated build surface. 3DGence INDUSTRY F420 is a perfect choice as a ULTEM 3D printer.

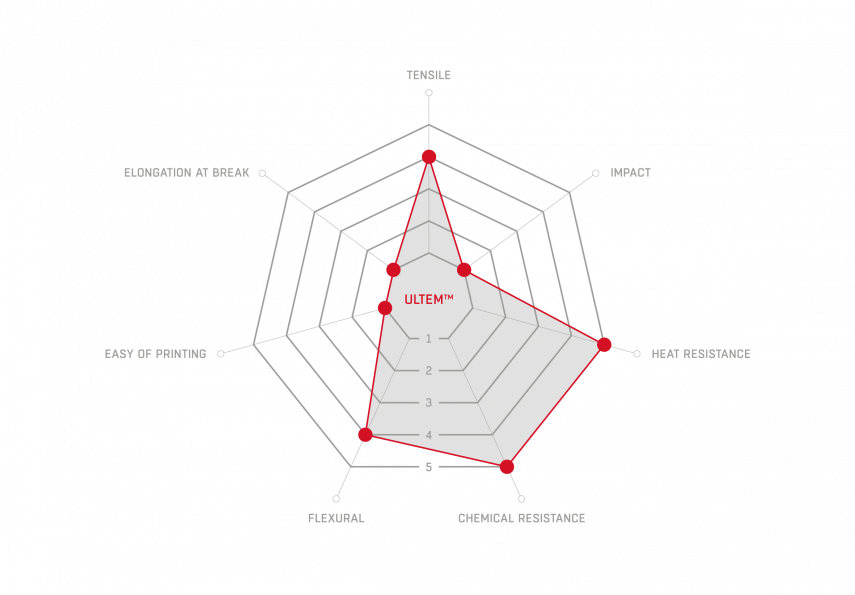

Its unique properties include high-temperature resistance, even up to 180ºC, resistance for natural and synthetic solvents, high dielectric strength and good thermal conductivity. PEI comparing to PEEK and PEKK shows slightly lower strength, stability and creep resistance.

Due to its properties material is widely used in railroad, aerospace and automotive industries. 3D printed ULTEM parts are used as metal parts replacements.

This material is also known as PEI (polyetherimide). Filament can be made from many different polymer grades, most common is AM9085F.

ULTEM™ 9085 is a trademark of SABIC.

Low volume production

Additive manufacturing is frequently more cost-effective than other legacy manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time tp market.

End Use Parts

In many instances the mechanical properties and surface characteristics of 3D printed parts meet and exceed the customer’s expectation, allowing their use in the actual product.

Prior to launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components, accelerating the iterative development cycle and time to market.

We will help you to choose the right material