Case study

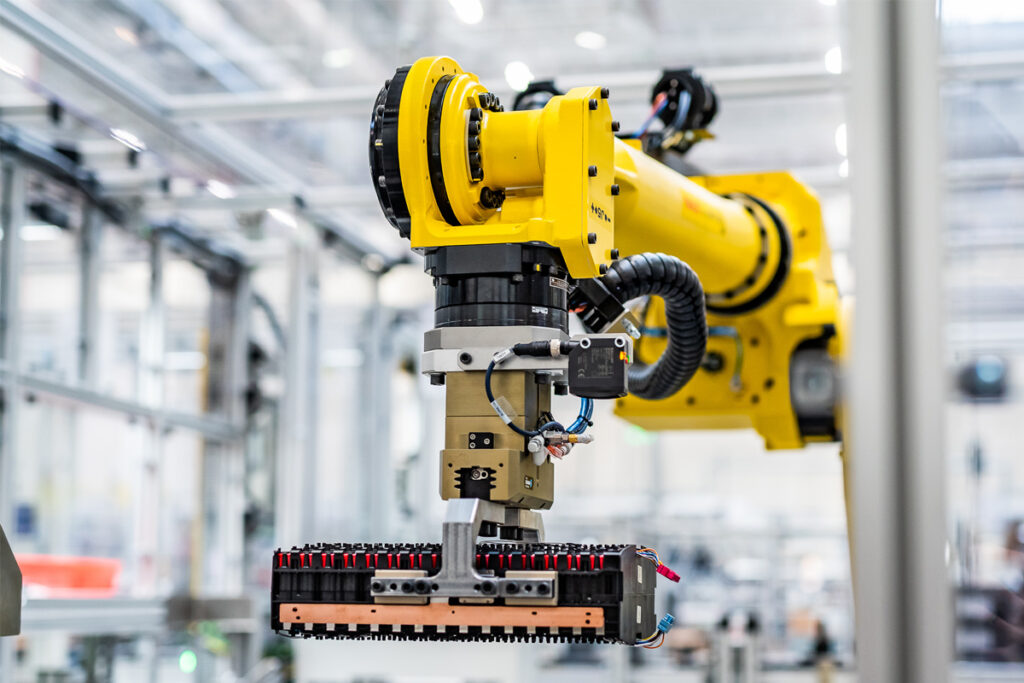

For over 200 years, Johnson Matthey used advanced metals chemistry to tackle the world’s biggest challenges. Nowadays, Johnson Matthey Battery Systems is a world leader in designing and manufacturing li-ion batteries for various applications – from e-bikes and energy tools up to energy storage and healthcare.

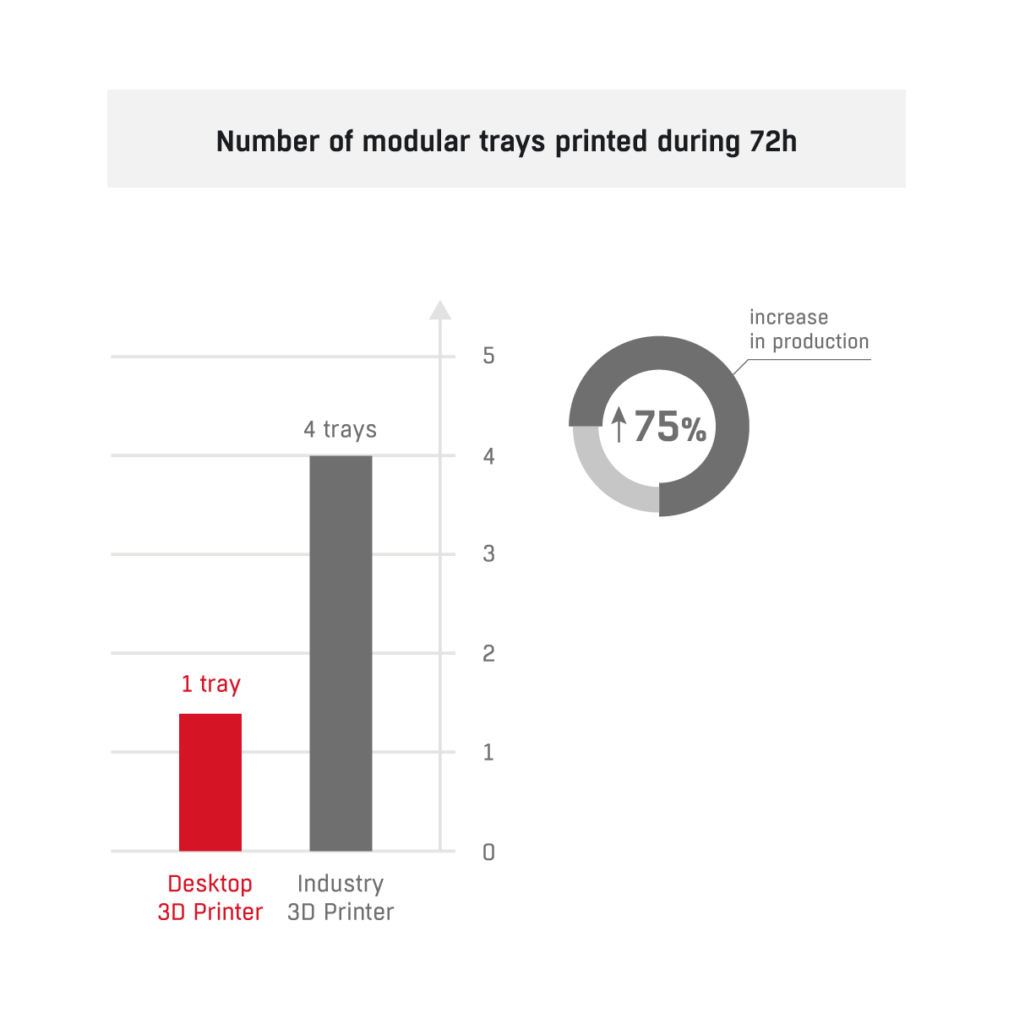

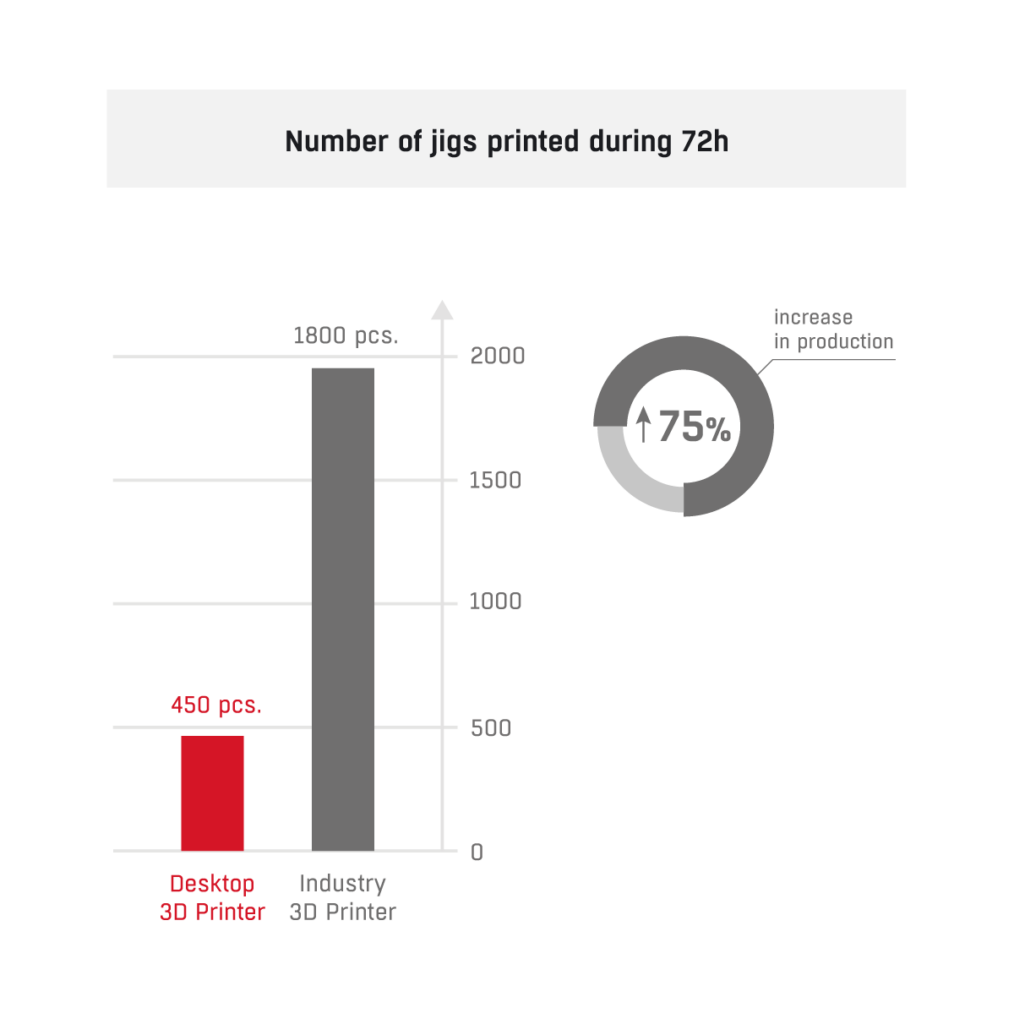

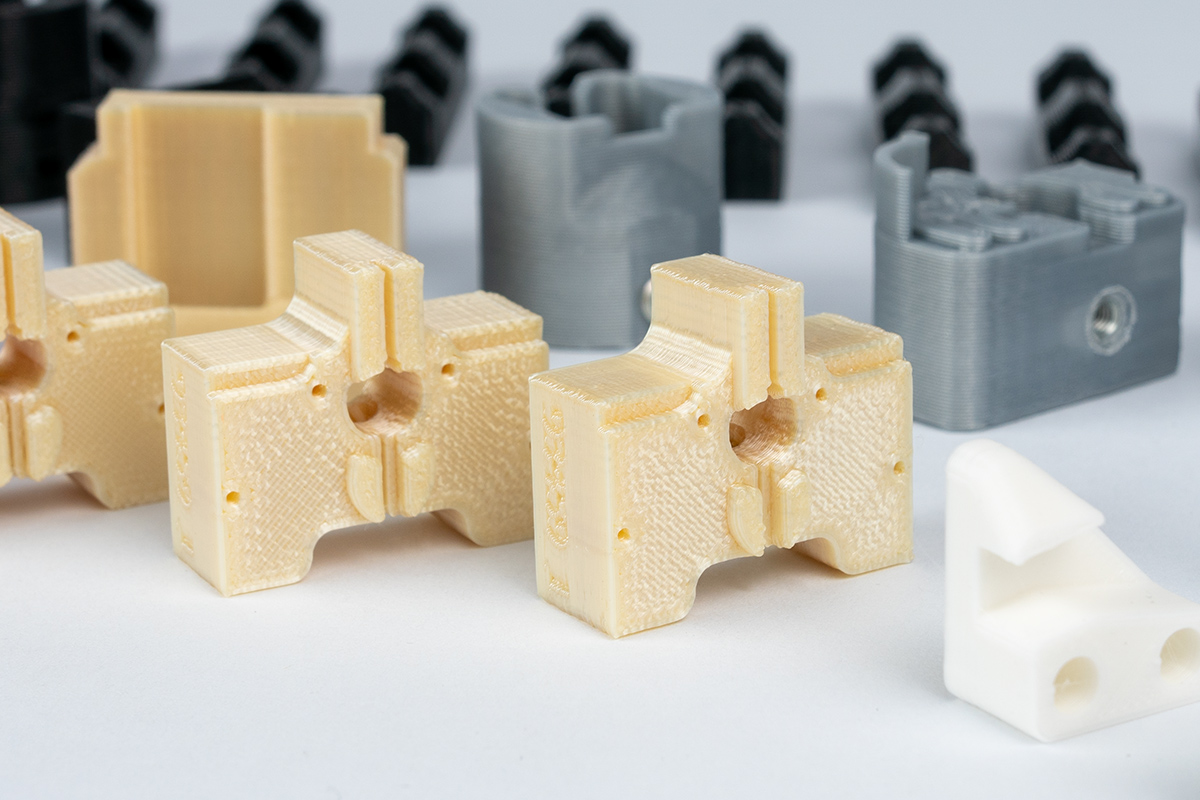

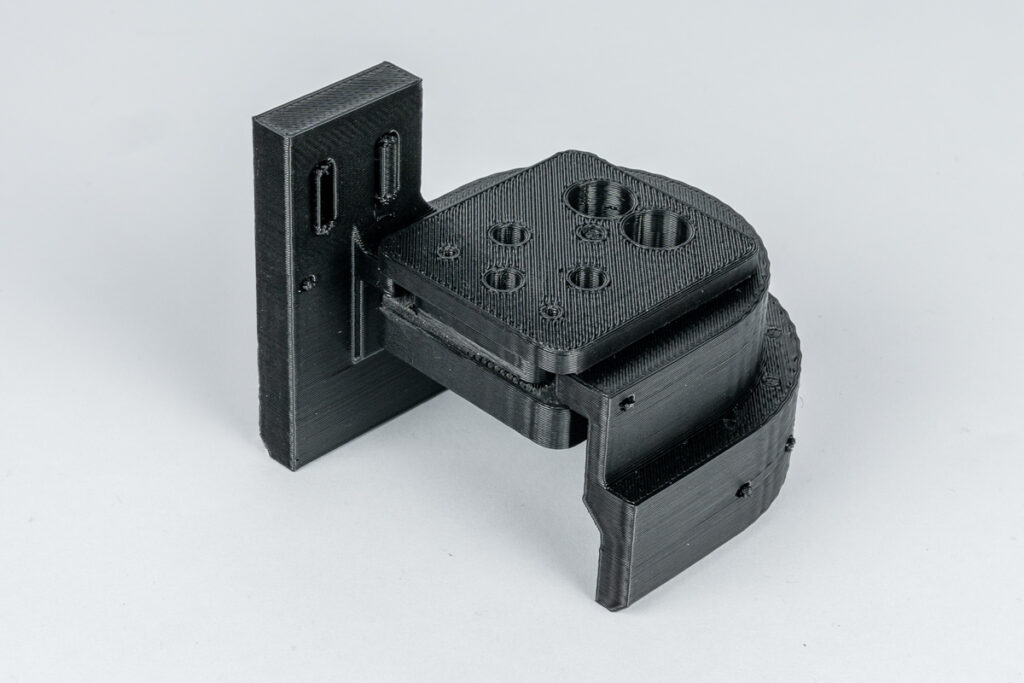

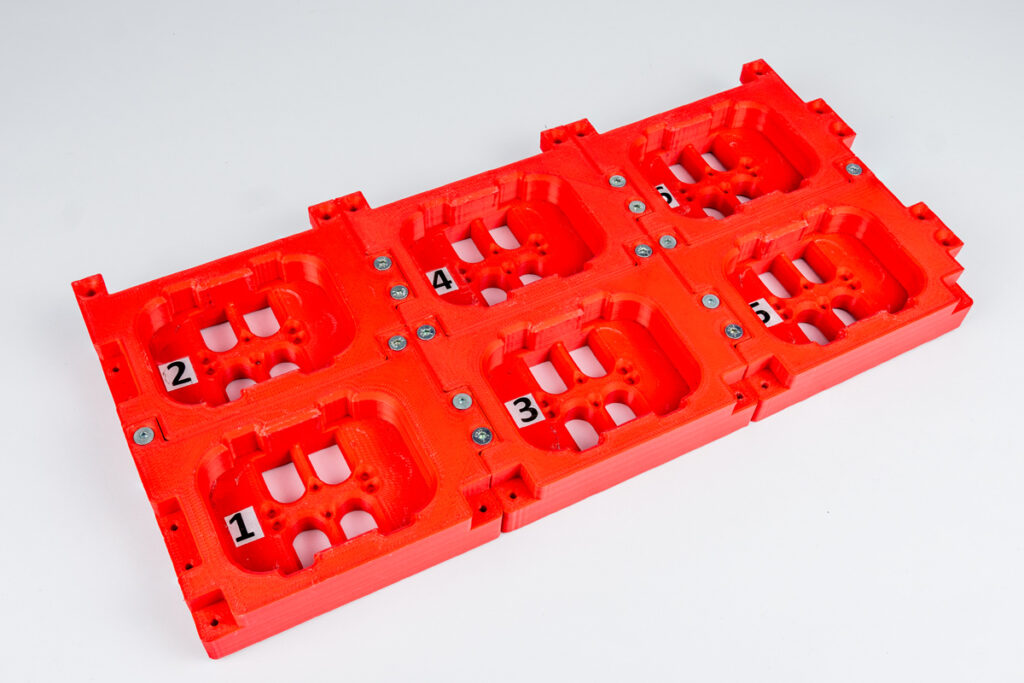

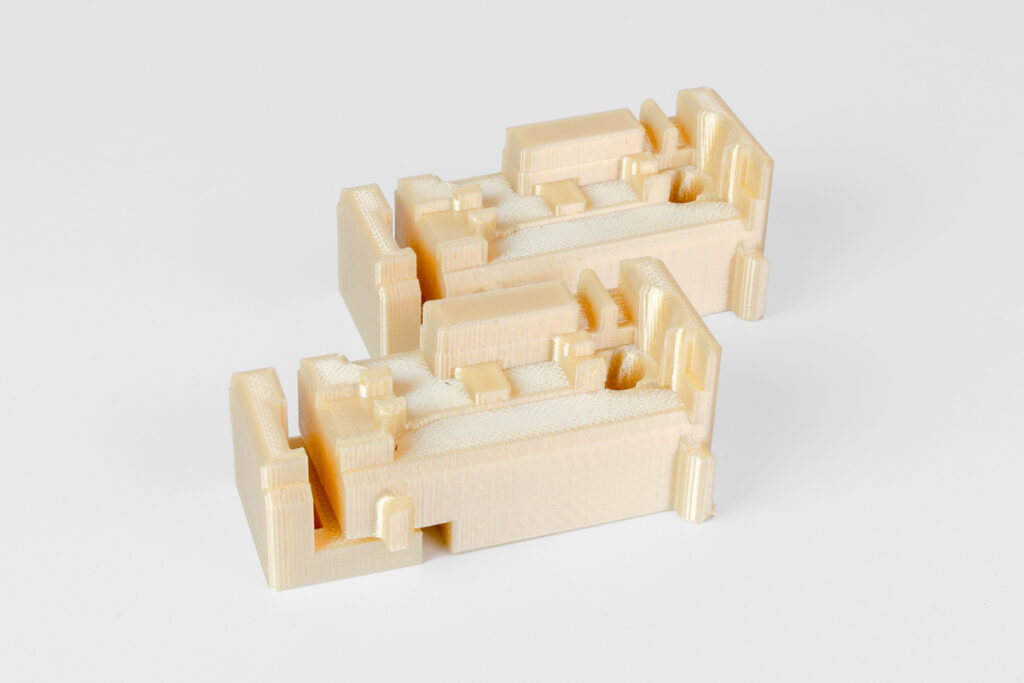

Need to serially deliver large- sized modular trays with complex geometric shapes

Used materials have to comply with the standards of manufacturing electronic equipment

Parts have to be 3D printed in desired strict tolerance, and the result had to be repeatable

Replace the desktop printers with an alternative industry technological solution that would decrease production costs

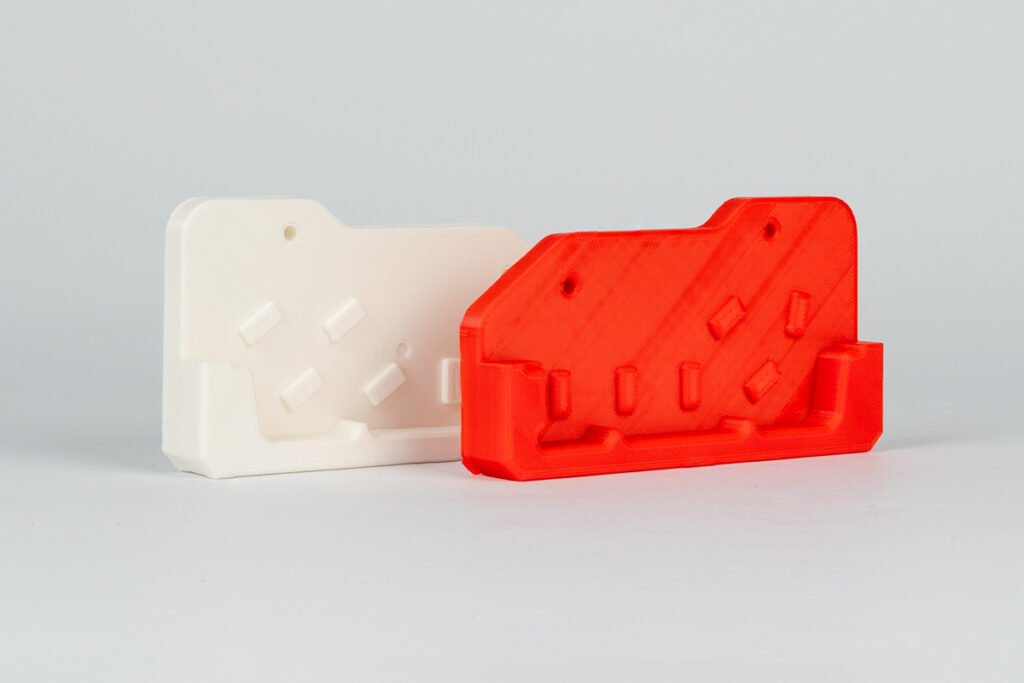

Initialy, we prepared prototypes on a desktop 3D printer. However, with this class of machine, we couldn't quarantee the dimensions stability of the prints and geometry limitations. We chose miling instead, but the costs of tooling inceased and the delivery time was too long. After engineering calculations, the only sensible solution was to implement an industriall 3D printer.

Jakub Szafranski, Test & Validation Team Leader at Johnson Matthey Battery Systems

Needed to print large- size parts

Required high quality parts. Needed materials with increased mechanical strength, high temperatures resistance and ESD standards

Faster prototyping and reduced line downtime due to waiting for spare parts

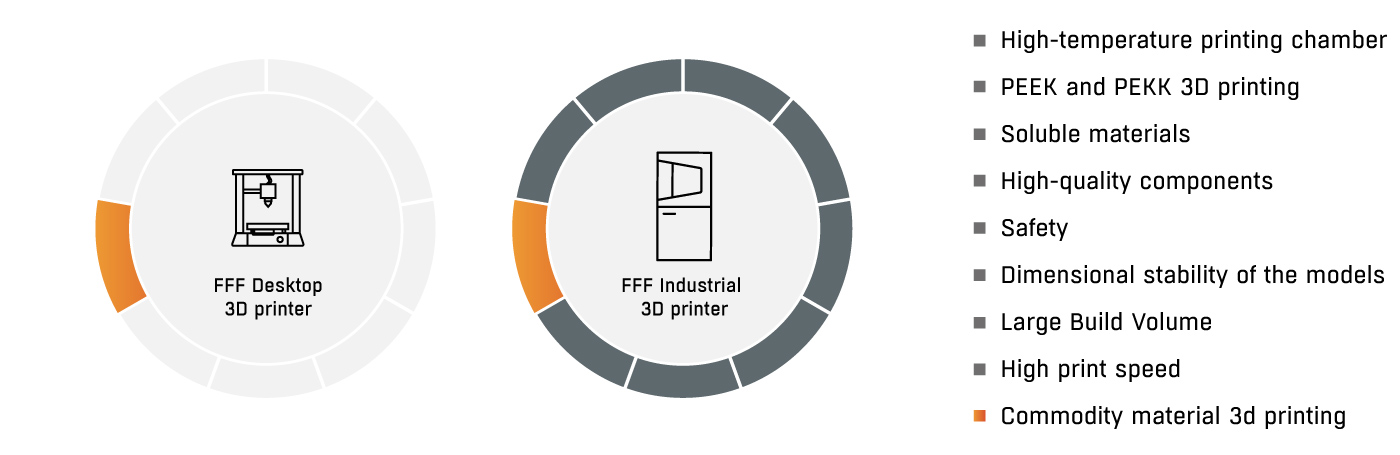

Desktop printer limitations and dimensional stability:

• Inadequate for large-size prints.

• Short lifespan of parts.

• Utilized milling technology initially.

Drawback of milling technology:

• Not cost-effective in the long run.

Preferred solution:

• Adopted an industrial 3D printer.

Enhancements for material longevity:

• Implemented an ecosystem, including a Material Managemnt System.

After the first month of use, we raised the technical parameters by 100%. The mechanical parameters are excellent ) nothing rubs off the parts). 3DGence industrial solution reduced the cost of maintenance and warehouse (less spare parts). INDUSTRY F421 provided a high dimensional accuracy and repeatability of printing detail.

Jakub Szafranski, Test & Validation Team Leader at Johnson Matthey Battery System

4 time longer lifetime of tooling

Required dimensional accuracy, repeatability and quality of parts

Lower maintenance cost

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.