Become a leader in Your sector – grow your business faster by using 3D printing technology for industrial applications.

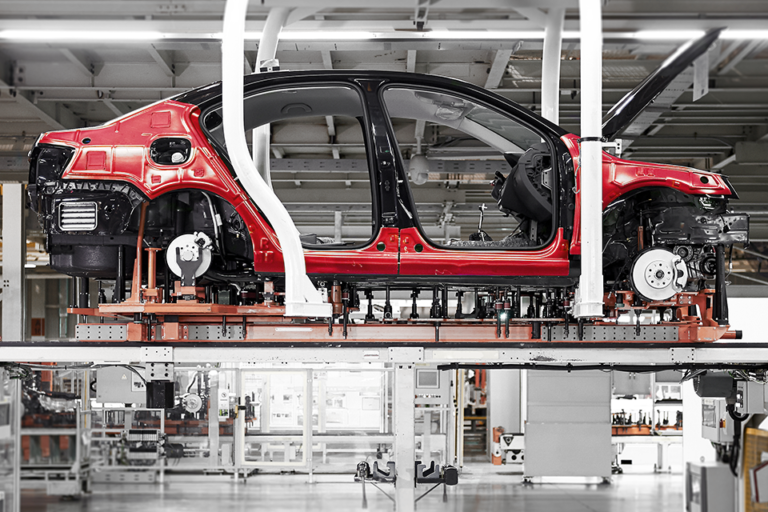

Since the beginning of mass production, consumer products have been manufactured using conventional technologies. Now it’s time to switch to more flexible and less-waste methods. Now it’s time for industrial-scale 3D printing. FFF (Fused Filament Fabrication) technology opens a new chapter in the world industry, including plenty of sectors. When we talk about today’s business requirements, all enterprises seek flexibility. FFF 3D printing provides a set of comprehensive tools suitable for those who want to create things on demand, need customization and design freedom, looking for unrestricted casting and prototyping. Demand-driven production decreases storage expenses too. The advantages of industrial 3D printing can be successfully used in the consumer products sector. Daily-use goods are widely produced with additive manufacturing (AM), which enables very complex applications and tailor-made solutions for both low- and high-volume production. AM assures a great level of reliability, consistency, and repeatability. The numbers do not lie. More and more companies manufacturing consumer products turn to 3D printing direction. Check our 360° approach and find out how you can capitalize on additive manufacturing.

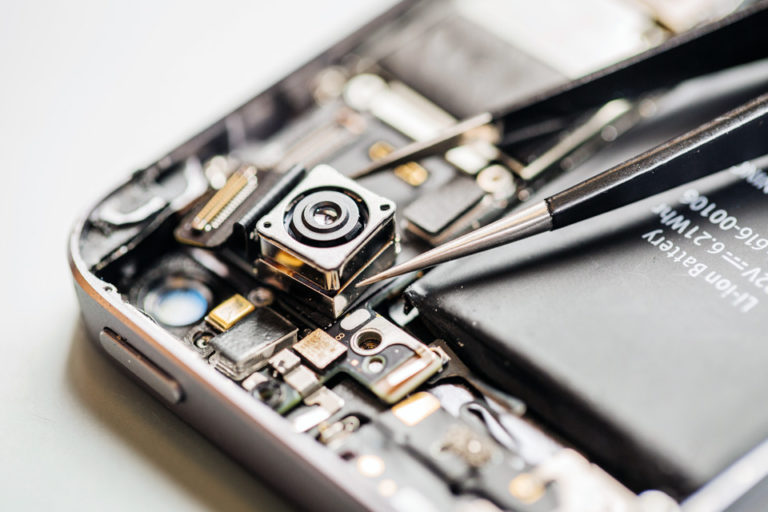

FFF 3D printing is the first choice if you plan to rapidly prototype a new consumer product. This technology will dramatically shorten your route-to-market time with even more prototyping iterations to perfect the product. Thanks to additive manufacturing you can easily broaden your portfolio, by testing different materials, geometrics, and functionalities. This way of creating new objects offers low-risk investment, reduced lead time, limited logistics costs, and endless freedom of personalization. With an industrial 3D printer, rapid prototyping has never been easier and more affordable. The importance of testing variants and implementing new products is a key factor of success in the customer goods sector. Rapid prototyping allows you to get prompt feedback and check how the product performs in a real environment, limiting time and money spent on market research. In other words, AM rises the chance of a successful implementation of a new product, reducing the risk of market failure and marketing slip-up.

Many market leaders already implemented additive manufacturing and take benefit of this technology. Furniture, car accessories, electric appliance, lightweight bikes, cycling helmets, perfume bottles, wearables, watches, jewelry, sports equipment, garden facilities, drones, shoe soles, eyeglasses, and even clothing… The list of end-use parts made out of thermoplastics is still growing. Do you also consider joining the trend and upgrading your production capacity with a reliable industrial 3D printer? The possibilities for using additive manufacturing in the consumer products industry are impressive and go far beyond cost-effectiveness, flexibility, and time savings. Printed elements have a nice appearance, smooth surface and are available in plenty of colors. What is more, 3D printing offers great design freedom, making complex geometries, and creating durable, personalized, eye-catchy objects. That is why additive manufacturing may let your products stand out from the massive production and attract the most demanding clients.

Many market leaders already implemented additive manufacturing and take benefit of this technology. Furniture, car accessories, electric appliance, lightweight bikes, cycling helmets, perfume bottles, wearables, watches, jewelry, sports equipment, garden facilities, drones, shoe soles, eyeglasses, and even clothing…

The list of end-use parts made out of thermoplastics is still growing. Do you also consider joining the trend and upgrading your production capacity with a reliable industrial 3D printer? The possibilities for using additive manufacturing in the consumer products industry are impressive and go far beyond cost-effectiveness, flexibility, and time savings. Printed elements have a nice appearance, smooth surface and are available in plenty of colors. What is more, 3D printing offers great design freedom, making complex geometries, and creating durable, personalized, eye-catchy objects. That is why additive manufacturing may let your products stand out from the massive production and attract the most demanding clients.

At 3DGence we design and create contemporary solutions that shape the industry. With a vast experience in the global 3D market, we perfectly understand the requirements of our clients with various backgrounds. Instead of delivering just a product, we focus on the whole process of creating new objects out of thermoplastics. We cover each stage of the journey, equipping clients with a vast range of filaments, true industrial 3D printers, top-quality filaments’ storage options (Material Management System – MMS), compatible software, and in-depth knowledge of our engineers. Our devices feature consistency, safety, and high performance. The flagship industrial 3D printers INDUSTRY F421 and INDUSTRY F350 have interchangeable modules, with two extruders each, that give superb flexibility and the potential of using different groups of filaments. Many customers who decided to join 3D printing evolution with 3DGence appreciate our support service and 3-year warranty. To find out more advantages of working with 3DGence, click the button below, describe briefly your business project, and let us tailor a solution suitable to your needs.

According to BCC Research global market for 3D printing in consumer goods manufacturing will reach $4.713 bln in 2024.

According to BCC Research 2019-2024 CAGR for 3D printing in consumer goods manufacturing will be 21.6%.

Based on The State of 3D Printing 2019 EDITION Sculpteo report 60% of respondents see 3D printing as a strength, they are ahead of their competitors.

Based on The State of 3D Printing 2019 EDITION Sculpteo report 48% of respondents invested more than $10 000 in 3D printing.

Find the best solution that fits to your needs, prototype faster and produce final parts batches from materials of various properties

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.