With its promise of compressing the time for getting a real part from a CAD drawing from weeks to hours, Additive Manufacturing has proliferated with a variety of technologies being now offered and dozens of companies claiming to offer industrial 3D printers.

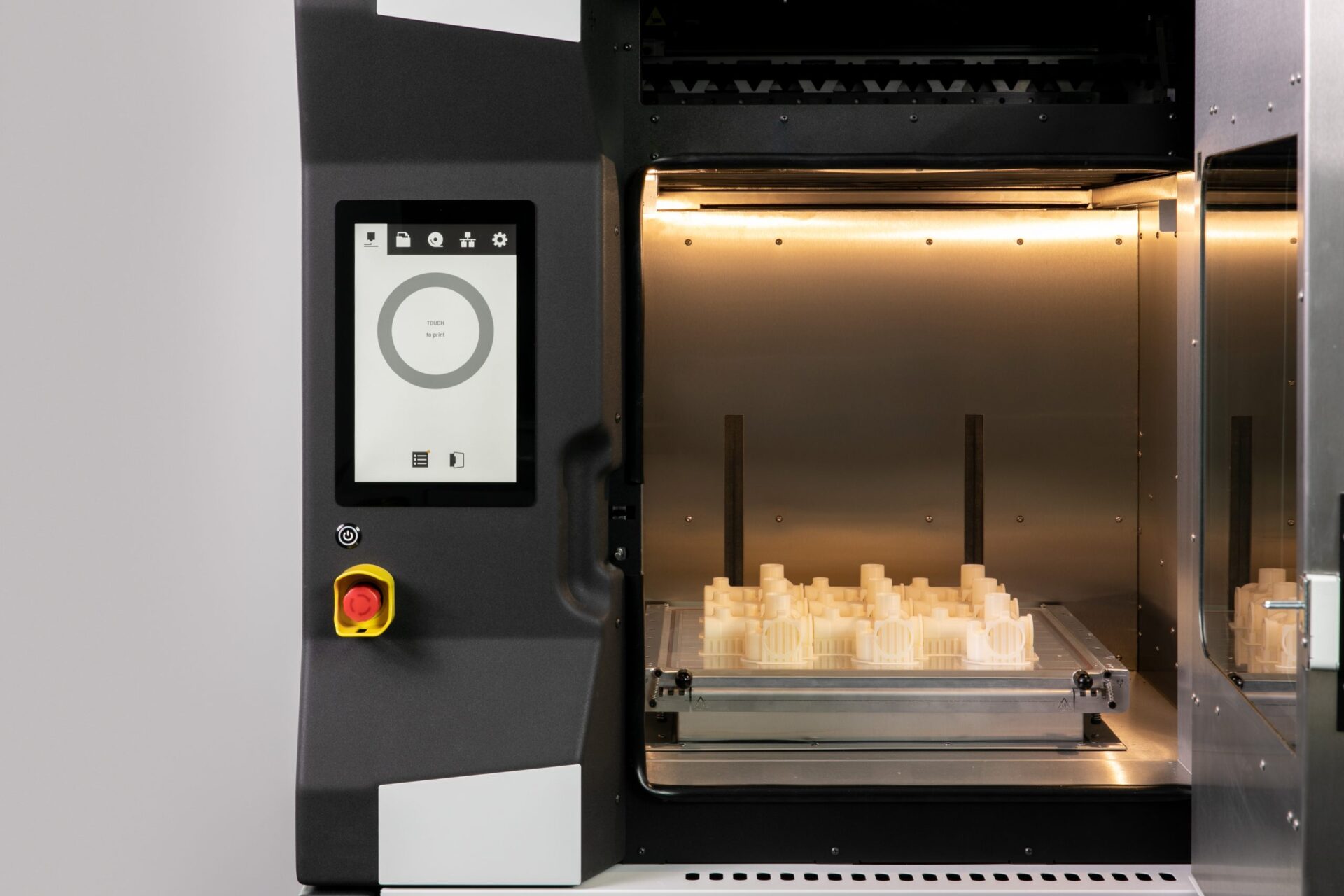

However, caveat emptor – relatively few of the machines on the market today are true industrial 3D printers – here’s why: an industrial 3D printer is a type of 3D printing machine that is specifically designed for use in a manufacturing or production environment. These printers are typically larger and more robust than consumer-grade desktop 3D printers, and are built to handle higher production volumes and larger print sizes. Some of the key features that differentiate an industrial 3D printer from a consumer-grade printer include:

Industrial 3D printers are capable of printing with a wider range of materials, including engineering-grade plastics, metals, and composites. The same features that make these materials meet stringent application requirements (temperature resistance, durability) can also make them difficult to process – for instance, highly abrasive composite materials can quickly wear down a consumer-grade printer nozzle.

Industrial 3D printers are generally faster than consumer-grade printers, allowing for higher production volumes and shorter lead times.

Industrial 3D printers are built to withstand the rigors of a production environment and are designed for long-term use.

Industrial 3D printers can deliver repeatable and reproducible performance, time after time.

Industrial 3D printers allow the production of end-use parts while logging process parameters and raw materials, enabling quality monitoring via traceability along the production process.

Have been specifically designed for industrial manufacturing and meet all of the above requirements, featuring: