Technology

Fused Filament Fabrication

- Ability to create internal infills for the part to have a lightweight structure, variable infill density

- Ability to use a wide range of advanced and high-performance engineering materials

- Unparalleled design freedom and short lead times

Contact info

Get in Touch with us!

Your idea is safe [we can sign an NDA]

Order process

-

Submit a request

-

Receive professional support in the selection of technology and materials

-

Order your parts

online -

Receive

your parts

Materials

Commodity Polimers

Advanced Engineering Polymers

High Performance Polymers

Technical information

How does FFF technology work?

- The process starts with a CAD model transformed into a printable format.

- Material is distributed by a moving print head that extrudes a heated thermoplastic in a pattern, path-by-path, onto a build platform.

- The build plate descends slightly and the process is repeated layer by layer until the build is complete.

Technology includes the use of a second material to create support structures that can be dissolved or physically removed after the build has been completed.

Finishing options

Trusted by Engineers

Why us?

We operate globally

Backed by a team with years of experience in the field of additive manufacturing technologies, design and machine construction

Trusted by thousands of engineers around the world

Q&A

How look like of FFF process printing?

FFF 3D Printing: FFF stands for Fused Filament Fabrication, which is a common 3D printing process. In FFF 3D printing, a thermoplastic filament is heated and extruded layer by layer to create a three-dimensional object. The printer nozzle moves in the X, Y, and Z axes to build up the object from the bottom up. The layers adhere to each other as they cool, creating a solid printed structure.

Why FDM is so popular?

Fused Deposition Modeling (FDM) is a popular 3D printing technology for several reasons: is cost-effectiveness, FDM supports a wide range of thermoplastic materials, including PLA, ABS, PETG, and more, FDM printers are relatively easy to set up and operate.

What is the difference between SLA and FFF?

SLA and FFF are two different 3D printing technologies, each with its own set of characteristics and processes. Uses a process called stereolithography, where a liquid resin is cured layer by layer using a UV light source. The object is built upside down on a build platform submerged in the liquid resin. Also known as FDM (Fused Deposition Modeling) or Fused Filament Fabrication, it involves extruding thermoplastic filament through a heated nozzle onto a build platform layer by layer.

Custom manufacturing services

3DGence Services-FAQ

As the Additive Manufacturing industry has quickly evolved, many organizations are evaluating options and technologies to speed up their design and engineering needs. Choosing the right technology, material, and application can be a daunting and expensive task. To help develop the right business case, or to keep capital and operating expenses down, many users are turning to additive manufacturing services to augment their internal capabilities and narrow the technology and application requirements for project success. Read more

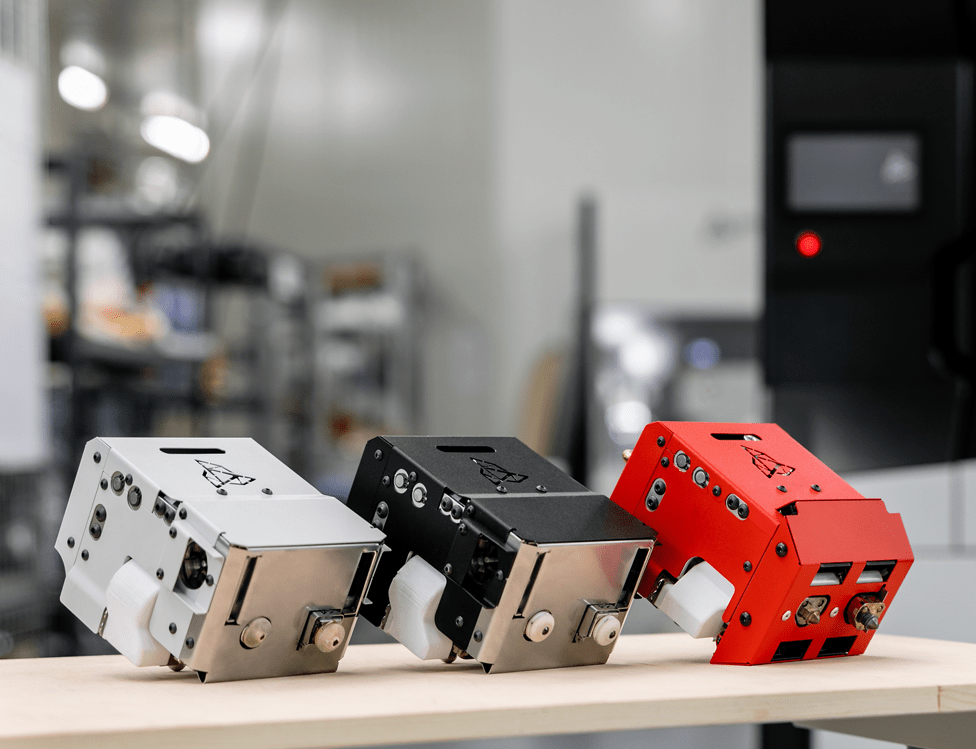

3D printer with a system of interchangeable printing module

Manufacturers of machinery used in various industries have been focusing their attention on the production of modular construction machines for many years. As a user, we get a machine in a basic configuration, and then, depending on our application and needs, we expand the purchased device with dedicated modules or tools specialized for a specific range of work. Read more

3DGence 3D Printing Services

Professional Additive Manufacturing Services are another option qualifying, evaluating, and adopting 3D printing technology to your business needs. Along with top-notch hardware and a wide range of materials, our company offers 3Dprinting services using multiple technologies. Read this article and explore the unlimited possibilities of AM services available at 3DGence. Read more

Deutsch

Deutsch Polski

Polski Français

Français Americas

Americas