Technology

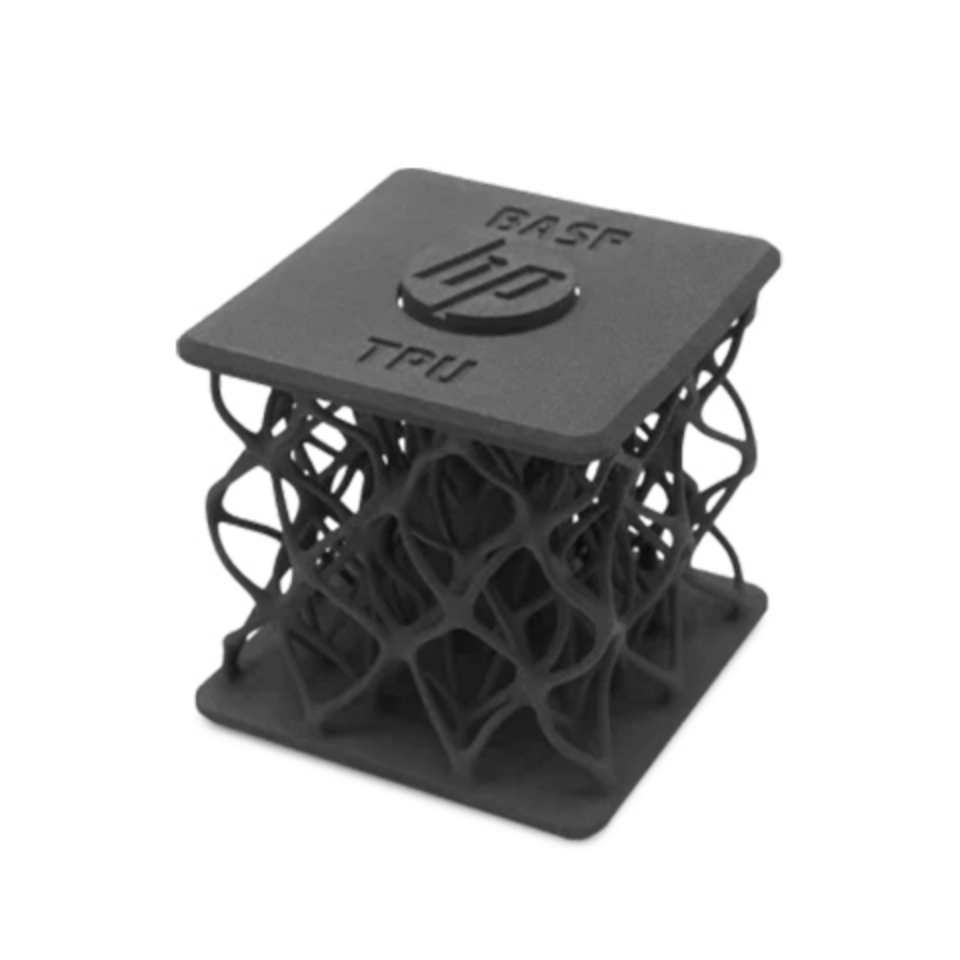

Multi Jet Fusion

- Production of functional parts of industrial quality with complex details

- High dimensional precision and high process repeatability

- Technology suitable for medium volume production

Contact info

Get in touch with us!

Order process

-

Submit a request

-

Benefit from professional support in the selection of technology and materials

-

Order your parts

online -

Receive

your parts

Materials

Technical information

Build volume

380 x 284 x 380 mm

Layer thickness

0,08 mm

Min wall thickness:

1 mm

(but possible 0,5mm as min. feature size)

Tolerance

± 0.3mm

How does MJF technology work?

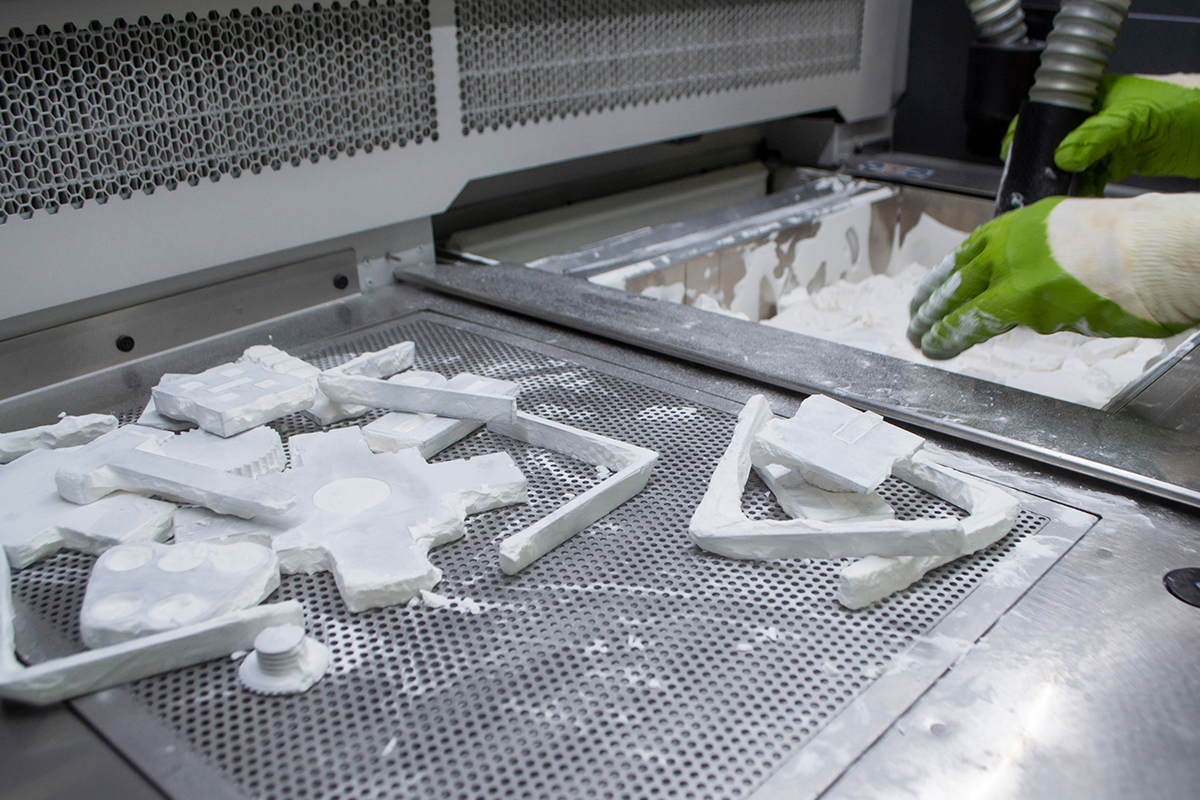

- The recoater carriage travels across the build area despositing a uniform thin layer of powder material.

- The printer’s ink heads selectively eject a fusing agent, drawing the layers of the parts as they pass, and detalling agent around the edges of the objects to increase their resolution.

- Aheat lamp solidfies and consolidates the areas where the agents are present.

- The build plate descends slightly and the powder recoater applies another thin layer of powder on top of the layer.

Trusted bY Engineers

Why us?

We operate globally

Backed by a team with years of experience in the field of additive manufacturing technologies, design and machine construction

Trusted by thousands of engineers around the world

Finishing options

Vapour Smoothing

Dyeing

Spray painting

Q&A

What are the advantages of MJF 3D printing?

MJF is known for its high-speed printing capabilities. It can build parts at a faster rate compared to some other 3D printing technologies. MJF supports a range of materials, including nylon-based powders. This versatility enables the production of parts with different mechanical and thermal properties, expanding the range of applications for MJF-printed components.

What materials are used in MJF technology?

In MJF, the materials used are typically powders that are selectively fused together layer by layer to create 3D-printed objects. The primary materials used in MJF technology include: Polyamide (PA) 12, HP 3D High Reusability PA 11, HP 3D High Reusability TPA enabled by Evonik, Ultrasint® TPU01 for HP Jet Fusion Printers, HP 3D High Reusability PP enabled by BASF.

What the Multi Jet Fusion 3D printing process looks like

The recoater carriage travels across the build area despositing a uniform thin layer of powder material. Than The printer’s ink heads selectively eject a fusing agent, drawing the layers of the parts as they pass, and detalling agent around the edges of the objects to increase their resolution.The next step is Aheat lamp solidfies and consolidates the areas where the agents are present. The build plate descends slightly and the powder recoater applies another thin layer of powder on top of the layer.

What are the characteristics of the prints in the MJF?

MJF can achieve fine layer resolutions, typically in the range of 80 to 120 microns. This allows for detailed and precise prints. MJF can achieve fine layer resolutions, typically in the range of 80 to 120 microns. This allows for detailed and precise prints.

What are the applications of Multi Jet Fusion?

MJF allows designers and engineers to quickly iterate and test designs before moving into full-scale production. MJF is suitable for low to medium volume production of customized or specialized parts, automotive industry, aerospace industry, medical applications, consumer goods, MJF is utilized in the production of jigs and fixtures used in manufacturing processes.

Custom manufacturing services

3DGence Services-FAQ

As the Additive Manufacturing industry has quickly evolved, many organizations are evaluating options and technologies to speed up their design and engineering needs. Choosing the right technology, material, and application can be a daunting and expensive task. To help develop the right business case, or to keep capital and operating expenses down, many users are turning to additive manufacturing services to augment their internal capabilities and narrow the technology and application requirements for project success. Read more

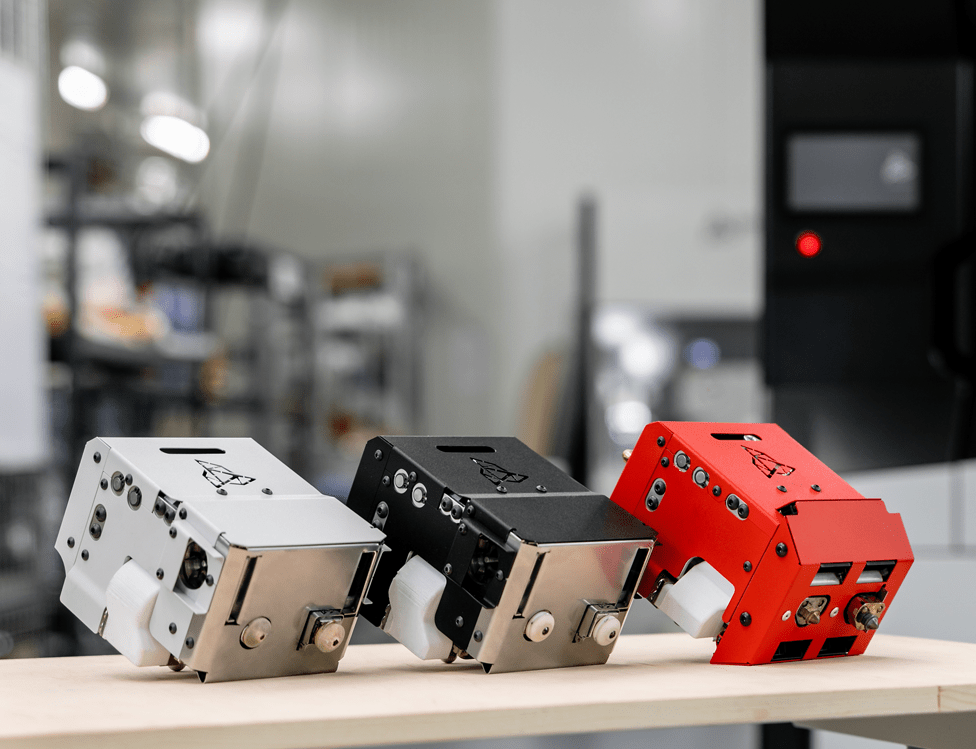

Interchangeable printing modules

Manufacturers of machinery used in various industries have been focusing their attention on the production of modular construction machines for many years. As a user, we get a machine in a basic configuration, and then, depending on our application and needs, we expand the purchased device with dedicated modules or tools specialized for a specific range of work. Read more

3DGence 3D Printing Services

Professional Additive Manufacturing Services are another option qualifying, evaluating, and adopting 3D printing technology to your business needs. Along with top-notch hardware and a wide range of materials, our company offers 3Dprinting services using multiple technologies. Read this article and explore the unlimited possibilities of AM services available at 3DGence. Read more

Automotive

Aerospace

Medical

Architecture

Production

Deutsch

Deutsch Polski

Polski Français

Français Americas

Americas