3DGence Sp. z o. o. realizuje projekty dofinansowane z funduszy Unii

Europejskiej.

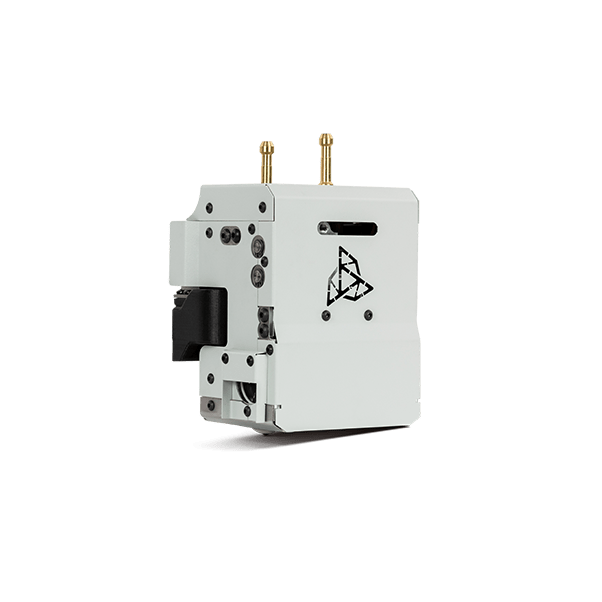

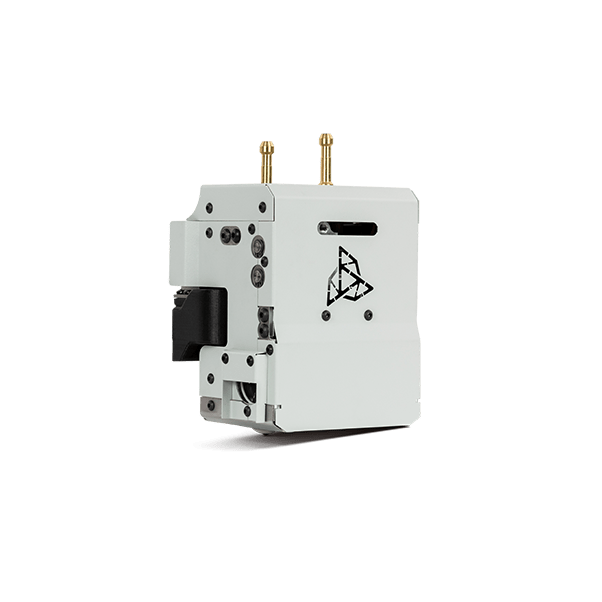

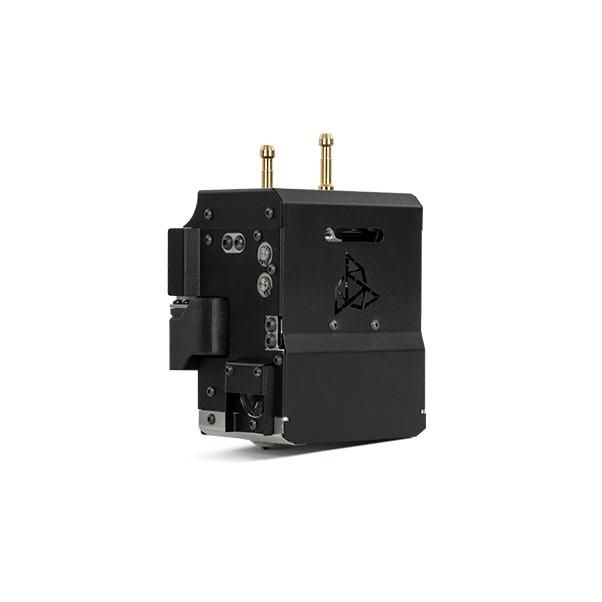

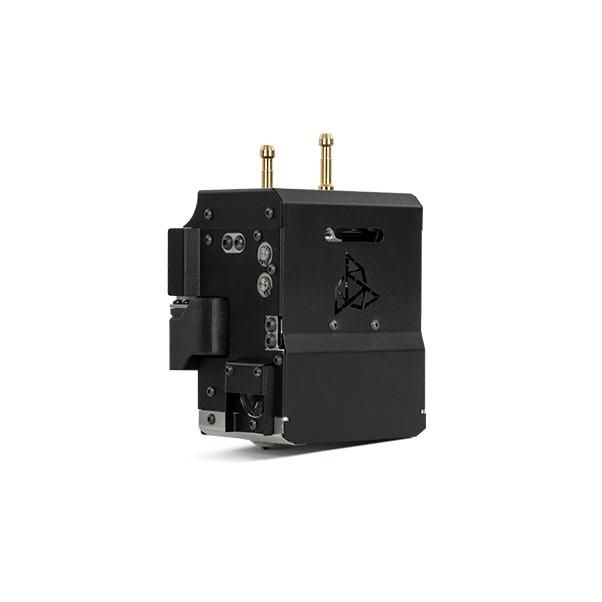

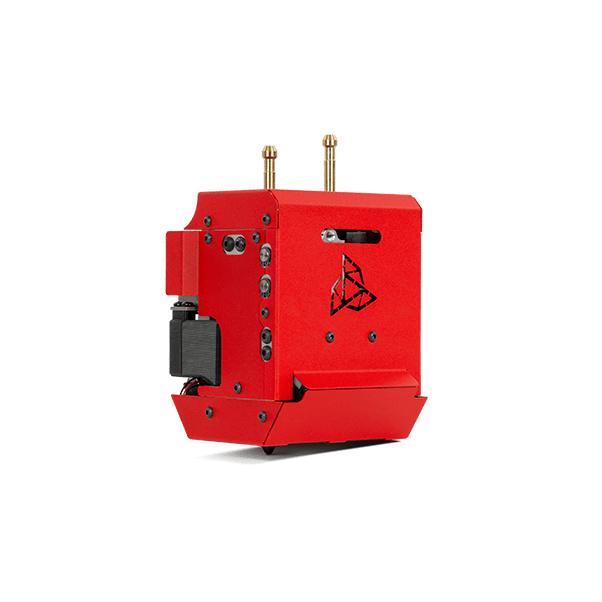

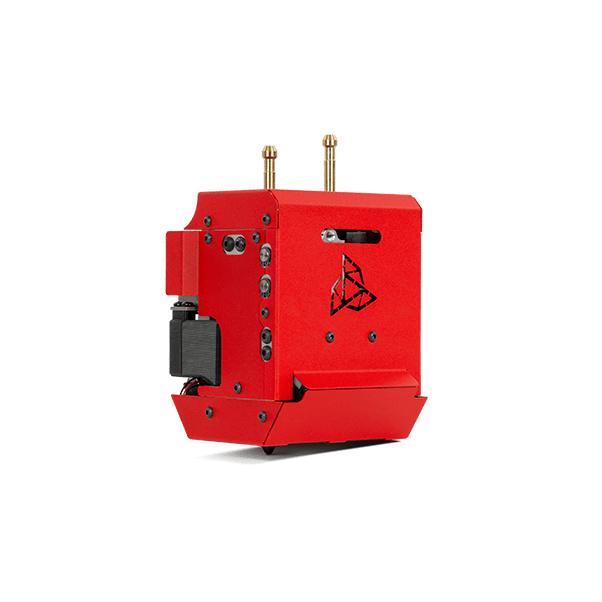

System modułowy zastosowany w 3DGence INDUSTRY F421 i INDUSTRY F350 jest praktycznym i opłacalnym rozwiązaniem. Drukarka z systemem modułowym jest unikalna w segmencie przemysłowych drukarek 3D. Możliwość zastosowania czterech różnych modułów w jednej drukarce 3D pozwala na wytwarzanie powtarzalnych modeli z najszerszej gamy materiałów. Każdy moduł jest dostosowany do konkretnej grupy materiałów w celu optymalizacji procesu drukowania. Wewnętrzna pamięć modułów oszczędza czas i eliminuje konieczność manualnej kalibracji. Wszystkie moduły są również wyposażone w dwie głowice i system podnoszenia nieaktywnych dysz.

M280 to podstawowy moduł drukujący dedykowany 3DGence INDUSTRY F421 i INDUSTRY F350, umożliwiający drukowanie materiałów użytkowych. Moduł M280 wspiera również możliwość druku podpór z rozpuszczalnego ESM-10.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

M360 to moduł wysokotemperaturowy, który umożliwia INDUSTRY F421 drukowanie modeli z ULTEM™ – wysokowydajnego polimeru o bardzo dobrych właściwościach mechanicznych, wytrzymującego oddziaływanie wysokich temperatur. M360 pozwala również na druk z materiałów inżynieryjnych, takich jak PC.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

M500+ może osiągać temperaturę do 500°C. Taka wysoka temperatura w połączeniu z grzaną komorą roboczą umożliwia drukowanie wysokowydajnych polimerów, takich jak PEEK lub PEKK na drukarce INDUSTRY F421. Moduł M500+ może drukować modele z PEEK i PEKK przy użyciu rozpuszczalnego materiału podporowego ESM-10.

3DGence DOUBLE enables 3D printing from water-soluble material BVOH, which allows removing supports without problems. Thanks to this solution you don’t have to manually deal with supports printed with HIPS or other breakaway materials.

An attempt to remove the supports mechanically may cause damage to the printout. BVOH support material gives the possibility of rinsing support material from the model and leave it in a perfect form.

Is the water temperature relevant?

The best effects of dissolving support material can be achieved with warm water. However, it can not be a temperature that threatens the building material. Water heated up to approx. 50°C will help remove the supports from the printout much faster. This process can also be improved by mixing water.

Finally, ensuring optimal conditions, such as in an ultrasonic cleaner, will dissolve the BVOH filament in just a few minutes.

Temperatura druku

Do 280°C

Do 360°C

Do 500°C

0,5 / 0,5 mm

0,4 / 0,4 mm

0,4 / 0,4 mm

ABS, ABS Carbon, Addigy® F1030 CF10, ASA, PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS, PC-CF, PC-ESD, ULTEM™ 9085

PEEK, PEEK AERO, PEEK-CF, PEKK-A, Victrex AM™200, ULTEM™ AM1010F

ABS, ABS Carbon, Addigy® F1030 CF10, ASA, PA6 Neat, PET, PLA, PP

ezPC-CF, LEXAN™ EXL AMHI240F, PC,

PC-ABS FR, PC-ESD

PEEK, PEEK-CF,

Victrex AM™200

HIPS (wyłamywany)

ESM-10

ESM-10

ESM-30

ESM-10

ESM-30

| Print Temperature | 340 – 500°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PEEK, PEKK |

| Support Materials | Dedicated breakaway ESM-10 (soluble) |

| Print Temperature | 265 – 340°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | PC, PC-CF, PC-ABS, PC-ESD |

| Support Materials | Dedicated breakaway (ABS) |

| Print Temperature | 190 – 265°C |

|---|---|

| Nozzle Diameter | 0,6 / 0,6 mm |

| Model Materials | ABS, ASA, PP, PA-CF |

| Support Materials | HIPS (breakaway) ESM-10 (soluble) |

| Print Temperature | 190 - 265°C |

|---|---|

| Nozzle Diameter | 0,4 / 0,4 mm |

| Model Materials | ABS, PLA, PP, ASA, PA, TPU |

| Support Materials | BVOH (water soluble) HIPS (breakaway) ESM-10 (soluble) |