3D printers are often accused of not being as good in quality as when parts are produced using injection moulding machines. This may have been true when the market was just beginning. With current technologies, the quality of industrial 3D printing does not differ from other methods and the printed parts can be successfully used in final products. This is what makes for good quality 3D printing. The days of expensive and inaccurate 3D printers are over. Even desktop printers, which used to be just an expensive curiosity and fancy, have now come down heavily in price and offer quite satisfactory print quality. Professional, industrial 3D printers are also becoming increasingly popular and can be found in factories and other businesses The durability of 3D printing from such a machine need not be at all different from an injection moulding machine. Especially if the right materials are used.

A number of factors influence the quality of 3D printing. This depends both on the performance of the printer itself but also on the software and filament used.

First and foremost, cheap 3D printers should be avoided. More often than not, those are Chinese manufacturers who only care that the product does not cost too much. Unfortunately, you have to pay for quality accordingly.

Starting with the structure – the quality of 3D printing is influenced by the materials used in the construction of the machine. The machine should be stable enough so that rapid movements of the heads do not cause the material to vibrate. In the worst case scenario, a sudden movement on any of the horizontal axes could tip the unit over.

When it comes to industrial 3D printers operating at high temperatures – avoid plastic housings which can degrade over time.

The axes should be mounted on heavy-duty rails and bars. Any imperfections will be reflected in the prints. The axes must be as rigid as possible so that vibrations do not affect the quality of 3D printing.

Information on the quality of the structure can best be found on the manufacturer’s website, product brochure or technical specifications. To maintain the quality of 3D printing, open and plastic structures should be avoided. The heating bench should be made of high-quality glass – such as borosilicate glass which is resistant to high temperatures and is also non-porous (providing a better quality first layer).

While the steel components make the machine heavier, they also provide longer life and greater stability.

Also, the right heating temperature has an impact on the quality of space prints. If the head or table temperature is too high, or too low, the print will have artefacts and imperfections. If the temperature is too low, the filament can become clogged in the nozzle and maintenance will be required. Conversely, too high a temperature will cause the material to melt on the table or burn in the head.

For example, if you plan to print with robust, professional materials such as PEEK or ULTEM™, you should choose a device with a high printing temperature. ULTEM™ requires a printing temperature of 350-380°C (depending on the manufacturer, this may be a little less or more). PEEK – from 370 to as high as 450°C. If you want to print with high-temperature materials, ideally your 3D printer should print at 500°C.

Other examples of high-temperature materials include VICTREX AM™ 200 (380-420°C) and PEKK (340-380°C).

In contrast, most large-format 3D printers not designed for the aforementioned materials heat up to around 300°C, allowing them to print from filaments such as PLA, ABS or nylon.

The choice of software is important for the quality of 3D printing. Printers without dedicated software, based on open source solutions, are problematic. Ready-made presets cannot always guarantee print quality. The time an engineer will spend fine-tuning the settings so that the quality is satisfactory could be spent on something else.

The print parameters in the software should first be set according to the material manufacturer’s recommendations. After a few test prints, the machine operator will be able to recognise which parameters need to be improved to obtain satisfactory 3D printing quality.

Talk to 3D printing experts

Quality does not always equate to durability. Even the prettiest prints, without artefacts or imperfections and properly smoothed, can be of low durability. Depending on the needs, we may forgo quality in favour of durability and vice versa, but some situations require both parameters to be maintained at a high level.

Below is a list of things that affect the durability of 3D printing.

Probably the most important issue in the durability of 3D printing is the material used. Low-quality PLA will quickly break or deform when exposed to heat. The same applies to ABS which will crumble if printed in poor quality.

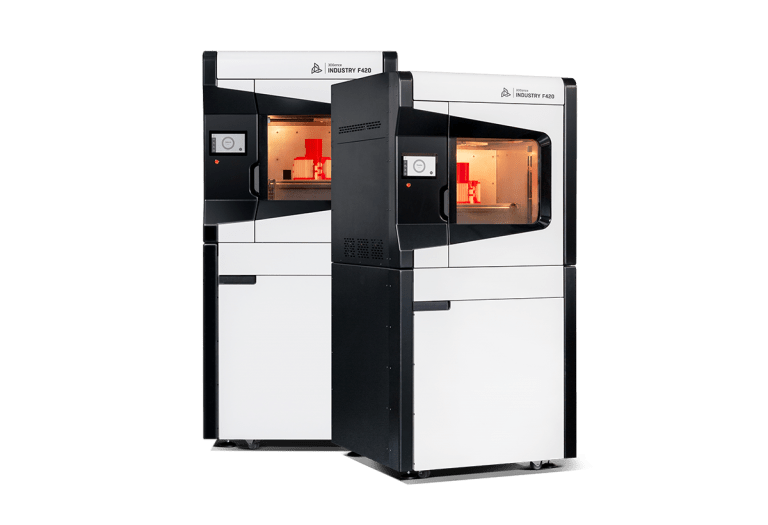

In order to achieve high durability of 3D printing, quality materials from reputable manufacturers should be used. Materials such as PEEK and ULTEM™ are particularly durable. The latter two require high heating temperatures, so not all available 3D printers are able to handle these filaments. Examples of printers that can print from PEEK include the 3DGence Industry F421 and its smaller equivalent, the Industry F350.

Some printer software offers ready-made presets for durable 3D printing.

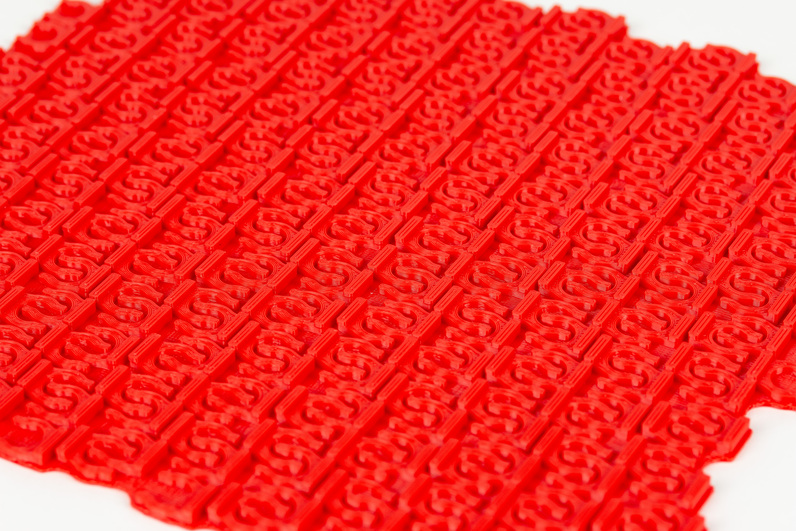

First and foremost, care should be taken to ensure that the right filling is in place. A hollow model will not be very durable. On the other hand, if you invest in full filling, such a print will be very difficult to destroy. Naturally, full filling requires a lot of filament and takes time. It is worth testing the various filling options available to get a satisfactory ratio of durability to the amount of material needed.

The quality of industrial 3D printing differs from home printers not only because of the possibility of using professional thermoplastics but also the temperature of the chamber.

Most desktop 3D printers do not have a closed structure which means that it is more difficult to maintain a constant operating temperature. Industrial units have a closed chamber, in some cases additionally actively heated which allows greater control during operation.

Temperature variations during printing can cause the model to delaminate. A closed chamber, affecting the quality of industrial 3D printing, maintains a constant temperature inside the machine and prevents problems such as delamination, or peeling of the first layer.

Talk to the 3Dprinting experts

As mentioned above, the closed chamber allows a constant temperature to be maintained during printing.

Something no home (desktop) 3D printer features is an advanced material management system. Many professional printers designed for industrial solutions have a dedicated chamber for filaments where the material can be further dried before being fed into the extruder.

An example of such a chamber is 3DGence’s MMS (Material Management System) solution. The system provides a high degree of control over the printing process from start to finish. Each material is tagged with an NFC tag – so the machine can send information directly to the software about the material and its parameters. The material is then dried in the 3DGence MMS solution. After printing, the model is subject to high-temperature annealing. This allows us to get rid of the tension in the print which significantly improves its durability.

Which machine, then, should be chosen to meet both quality and durability criteria? Cheap printers from little-known manufacturers should certainly be avoided.

Desktop printers are not suitable for industrial solutions. Buying such a printer for an industrial company will only be a waste of money as the prints will not meet the quality requirements. If you are looking for a 3D printer for your business that will offer high-quality, durable prints, then it is best to take advantage of offerings from reputable manufacturers such as 3DGence.

Remember that it is not just the machine itself that affects quality. You also need to invest in the right filaments and software to get durable prints.

Should you have any further questions, our experts will be happy to talk to you.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.