Professional Additive Manufacturing Services are another option qualifying, evaluating, and adopting 3D printing technology to your business needs. Along with top-notch hardware and a wide range of materials, our company offers 3Dprinting services using multiple technologies. Read this article and explore the unlimited possibilities of AM services available at 3DGence.

There is no question that 3D printing is a global ternd, boosting Industry 4.0 and attracting growing attention from wide range of industries and companies. Enhanced design flexibility, reduced assembly time, fast turn around, superb quality, an impressive range of materials and technologies, avoiding some limitations typical for conventional production methods Am provides a long list of possible advantages that 3D printing provides at many points. A key benefit and advantage to your company is that you do not need a professional 3D printer to benefit from additive manufacturing. 3D printing services at 3DGence will allow you to find your prerred way of qualifying, evaluating, and utilizing AM. We can help you with tooling, rapid prototyping, concept modeling, and manufacturing end-parts, jigs&fixtures, or deliver a custom-tailored solution. When choosing 3DGence services engineers – with multi – industrial experience, and hundreds of successful projects delivered, post-processing, consulting, R&D, rendering, and other custom engineering services.

3D printing encompasses different ways of manufacturing items out of different materials. Many of them are available at 3DGence services. This diversity gives our customers the full array of possibilities, enabling companies from different industrial projects to streamline and thrive thanks with 3D printing. No matter which sector you operate in, additive manufacturing may help you optimize processes, save time, and reach new customers. The greatest asset of 3D printing services is flexibility, which comes from numerous technologies and compatible materials. To give you a profound insight into AM potential, we explore all types of technologies that fall into 3D printing services offered by 3DGence

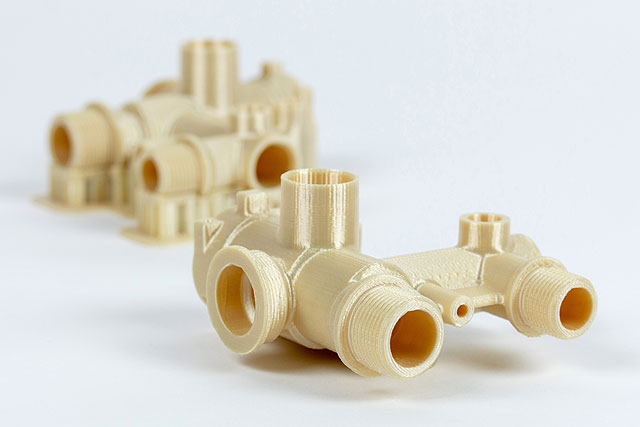

also known as FDM Fused Deposition Modeling FFF encompasses the sequential application of thermoplastic ( polymer ) layers along specific paths. The elevated temperature of the material extruder causes the polymer to melt, enabling the construction of the desired geometry layer by layer. This method permits the production of components using various polymer types. ( commodity, engineering, and high-performance grades), granting FFF a diverse array of applications and providing substantial design flexibility and freedom. FFF presents a broad selection of materials, spanning from prototype-grade to metal replacement composite and advanced materials. A professional 3D printer is a powerful tool, ready to take on multiple industrial challenges. The technology is applied in the most demanding industries, such as automotive, aersopace, train, defence, consumer products, medical, HVAC or machine production. Making new objects out of thermoplastics is a quick and reliable method for rapid prototyping, producing jigs&fixtures, molds, and end-use parts.

1. reduced time to market and cost of making new objects;

2. superior proce-to quality ratio

3. freedom of design;

4. variety of applications and wide range of materials;

5. robust resistant, and strong printouts ready to work in extreme environments.

The MJF printer uses inkjet heads to dispense selectively a fusing agent, drawing the layers of the parts as they pass, and detailing agents around the edges of the objects to increase their resolution. A heat lamp solififies and consolidates the area where the agents are present. The build plate descends slightly, and the power recoater applies another thinh layer of power on top of the previous layer. Operating MJF printer, you can use the following materials:

• PA12

• PA12 Glass Beads

• PA11

• PP

• TPA

• TUP

The materials differ in their properties and thus applications, offering: good resistance to chemicals, impacts, and UV light, good ductility, and elongation-at-break. MJF is suitable for manufacturing functional parts festuring industrial quality and complex details, superb dimensional precision, and high process repeatability. Many companies use MJF for series production in medium- volume range, and it has a good performance/cost medical, housings, jigs & fixtures, and tooling

SLS is a method in which layers of thermoplastic polymer powder are successively fused using a laser. Moving according to a CAD design model, the laser melts the polymer power, creating a solid 3D-printer part. The build plate descends slightly and the powder recoater applies another thin layer of power on top of the previous layer. This process repeats layer by layer until the part is done. SLS has some important assets. Firstly, the printing process does not require support structures. This allows the production of very complex designs without the need for mechanical removal of supports and the risk of damage or loss of visual quality of the part. SLS reduces time to market and allows the printing of items featuring almost isotropic mechanical properties, similar to injection molding.

The technology utilizes different materials, with different applications:

• TPU — flexible material,

• PAEK — chemical resistance, flame retardant materials with railway and aerospace applications,

• PA12 — a group of materials with a wide range of applications, e.g., medical, food contact, and vehicles. The material comes in various including fiber-reinforced or flame retardant,

• PA11 — basic material with a wide range of applications similar to PA12.

This technique is particularly well-suited for prototyping but also for low-volume production of end-parts. SLS provides top-quality printouts and thus is widely used in the most demanding businesses, including automotive, aircraft, railway, medical, and motorsport. Objects made by SLS printers work well as prototypes, jigs & fixtures, footwear & lifestyle parts, seals and gaskets, and substitutes for injection molded parts.

The SLA is a great option for applications requiring tight tolerances and smooth surfaces. The principle of operation is as follows. The build platform shifts down into liquid resin and recoater/rollers squeeze resin out from under the part to generate a thin, even layer. The laser/mirror combination directs the beam according to the path needed for creating the object. The polymer resin is selectively cured, with laser light. There is a wide range of advanced materials that differ in their properties and thus in their applications:

• general-purpose resins,

The technology offers the user great design freedom and printing of complex geometries in metal. How it works? The recoater carriage travels across the build area depositing a uniform thin layer of metal powder. The printer uses a laser to melt metal powder and fuse it into a solid part. Using a CAD design model, the laser melts the metal precisely at the predefined points in the powder bed. The build plate descends slightly, and the powder recoater applies another thin layer of powder on top of the previous layer.

DMLS uses a range of metals, such as:

Due to the materials’ diversity presented above, DMLS offers a vast range of industrial applications. The technology is widely used in aerospace, automotive, medical, tool and turbomachinery sectors.Depending on the chosen material, the printed parts manufactured with DMLS technology may offer various parametersin terms of mechanical properties, electrical and thermal conductivity, corrosion and heat resistance, and so on.

• The process of printing with PolyJet technology starts with a CAD model transformed into a printable format. Drops of photopolymer are jetted onto the build platform by piezoelectric jetting heads. Then the material is cured with UV lamps to bond layers. The process repeats layer by layer until the build is completed. By choosing PolyJet, you can use the following materials: VERO®, VeroClear, Agilus30™, Agilus30™ Colors, Digital ABS Plus, and Rigur.

Depending on the selected material, PolyJet gives you:

• wide range of capabilities, including the creation of complex geometries, intricate details, full-color combinations, transparencies, and flexible parts – all in a single model,

• limitless design possibilities by creating smooth, detailed parts.

The technology is suitable for different applications across various industries, to create accurate, realistic, visually stunning models from prototyping to low-volume production without the need for tooling. PolyJet offers multicolor diversity, too. These features of printouts are desired in many sectors, e.g., the medical industry , which uses different colors to tag different parts of anatomical models.

Having almost a decade of experience in 3D printing, 3DGence has earned trust of progressive and innovative global companies, such as NASA, Volkswagen, GSK, Würth, Siemens, SAAB, Microsoft, and many more. Our portfolio embraces industrial business cases from different sectors and multiple AM technologies. Industrial 3D is our Business™ and we understand and practice industrial – scale full- lifecycle additive manufacturing since our inception. By rising to the requirements of the market, we provide an solution ecosystem, includng true-industrial 3D printers, monitoring, as well and wide range of compatible filaments and material science.

Do you want to partake in the 3D printing evolution and commerce benefiting from additive manufacturing? 3DGence printing services offer you the optimal way to get familiar with the unprecedented possibilities of the latest technologies. Contact our experienced staff to provide the project requirements using the contact form. We encourage recommend suitable techniques and materials, as well as the scope, timeline, and roadmap of your project. Once the project scope and quotation is discuss project details, schedule, and cost. The best time to start your 3D printing journey is now. Contact us and we will help you evaluate and determine how to best utilize additive manufacturing and industrial-grade technologies for your business requirements and goals.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.