Let’s start with a short explanation. In this article, sometimes we use ABS filaments (plural), as ABS itself might occur in different variations, e.g., Smart ABS, ABS-CF, ABS-FR and more. ABS can also work as a base of other filaments, e.g., PC-ABS. However, talking about ABS (single), we think about Acrylonitrile Butadiene Styrene, which has become one of the most popular 3D printing filaments for decades. This material falls into a category of commodity polymers – cost-effective filaments with average resistance and decent mechanical qualities. Another popular member of the commodity plastics group is PLA (Polylactic Acid). The commodity polymers are used both for industrial and consumer-grade applications, but the results you get from consumer-grade machines are most of the time, significantly worse than from industrial ones.

Getting to the point, ABS filament is a versatile thermoplastic material that allows professionals and individuals to create customized 3D printed models. It possesses chemical resistance to acids, alkalis, and alcohol. Although ABS filament is not soluble in most substances, it can be dissolved in acetone, commonly used to post-process the models and achieve a smoother surface finish or glue two ABS parts together.

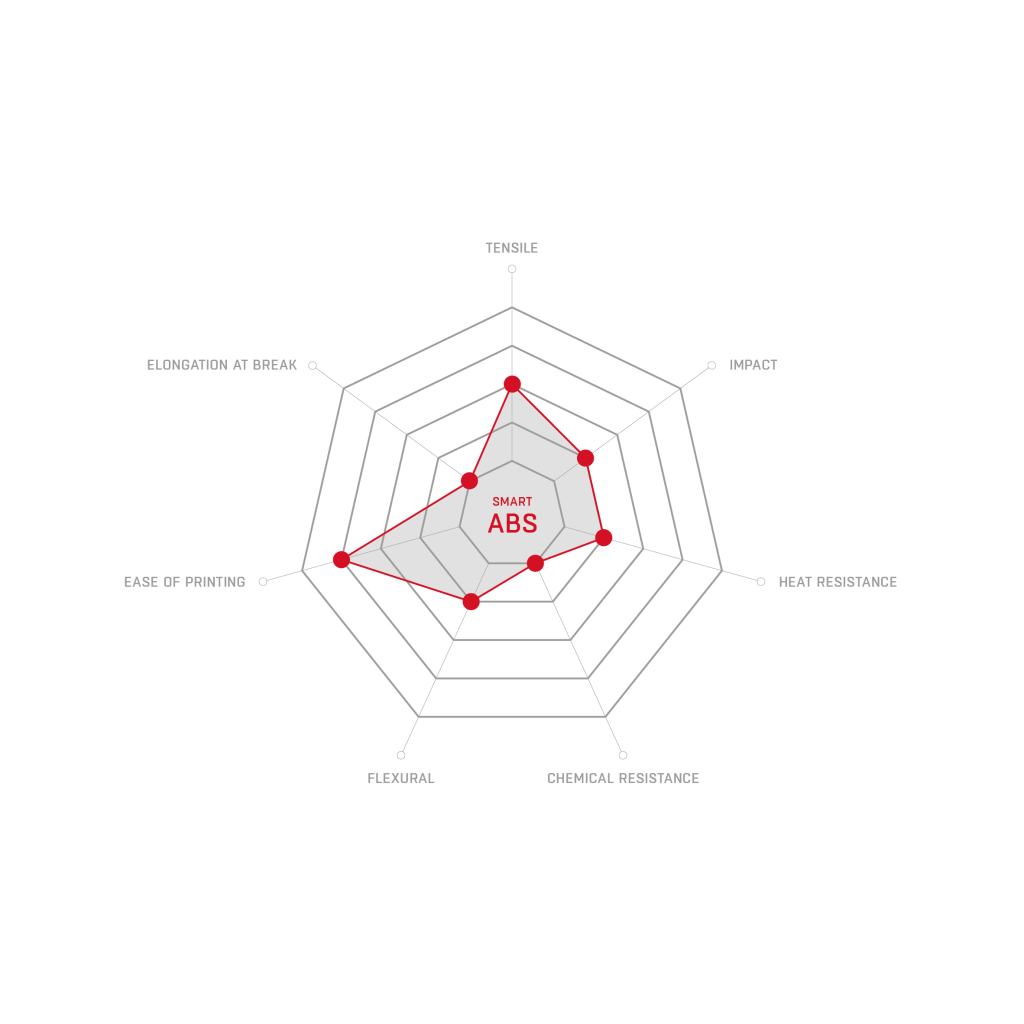

As with any other material, ABS has some advantages and disadvantages. Here are the most important facts regarding ABS 3D printing. On the one hand, ABS is a cost-effective solution with decent strength, minimal post-processing requirements, and sufficient electrical insulation. It offers high resistance to heat, mechanical stress, and chemicals. What is more, ABS is available in a diverse range of colours. It works with soluble and breakaway support material. On the other hand, printing with ABS generates toxic fumes and odours. All INDUSTRY line 3DGence 3D printers are equipped with filtration units that protect from those harmful particles. Printing with ABS may be difficult; it requires specific settings and features for successful printing. The risk of warping and poor layer adhesion may be a problem when a desktop 3D printer is used. Low UV resistance is also a typical weakness of ABS filaments.

Due to its low price and good heat and chemical resistance, ABS filament is utilized in multiple industries: automotive (dashboards, bumpers, trusses, buttons, internal fittings), aerospace, housing appliances, customer products industry, and robotics. Companies use it for functional prototyping, low-volume production, tooling, and printing end-use parts. However, professional applications are not the only assignment of ABS. 3D printing enthusiasts can print some elements using a desktop printer. Cosplay suits, toys, sports equipment, decoration pieces, enclosures for electronics, or musical instruments can be given as popular consumer-grade applications of ABS. A fun fact is world-famous LOGO bricks are mainly made out of – surprise, surprise – ABS filament. The Danish manufacturer has used ABS since 1963.

What 3D printer ABS settings are required in order to gain top-quality printouts? Before we move to the specific printer settings, it is worth noticing that ABS requires constant temperature during the printing process to prevent issues with cracking, warping, and layer separation. How to avoid these kinds of problems? A professional 3D printer with a heated chamber and heated print bed will solve the issues and allow you to reach the full potential of additive manufacturing with ABS filament.

Heated chamber

and heated print bed

Advanced filtration

system

Material Management

System

• Extrusion temperatures: 240 – 260 °C

• Bed temperature: 80 – 90 °C

• Chamber temperature: 70 – 90 °C

The specification above regards 3DGence printers’ that are compatible with 3DGence ABS filament. In particular, our devices: INDUSTRY F421, INDUSTRY F350, and INDUSTRY F340 can offer you the best results of printing with Acrylonitrile Butadiene Styrene on an industrial scale. Each model works as a 3D printer for ABS with soluble support material.

Being a globally-known producer of industrial printers and filaments, we understand that implementation of 3D printing might be challenging. Therefore, we propose a comprehensive approach covering each step of applying additive manufacturing to your business. We pay attention to each process phase, giving you the most effective, tailor-made solution instead of just the product. Tesla, GSK, SAAB, NASA, Volkswagen, Alstom, Tefal, and Microsoft – here are some companies that benefit from 3DGence printers. No matter if you want to buy ABS filament, look for proper printing settings, or consider joining a growing list of businesses that already introduced 3D printing technology, feel free to contact our advisor and find out how 3DGence can help you to enter the world of additive manufacturing.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.