Key characteristics of industrial 3D printing solutions are repeatability and reproducibility. While these words are sometimes used interchangeably (with repeatability being used more often to denote reproducibility), they represent in fact very different aspects of a robust additive manufacturing process

In additive manufacturing, Repeatability refers to the consistency with which a particular process or system produces the same result each time it is used. For example, if a 3D printer consistently produces parts with similar dimensions and surface finish each time it is used, it could be considered repeatable. For instance, during the recent COVID-19 pandemic many manufacturers developed 3D printed parts for respirators, shields etc. In such rapid production or mass customization applications, when a machine is assigned production of the same part (or very similar), selecting a 3D printer with repeatable performance and process traceability will give the manufacturing team confidence in the production quality and schedule

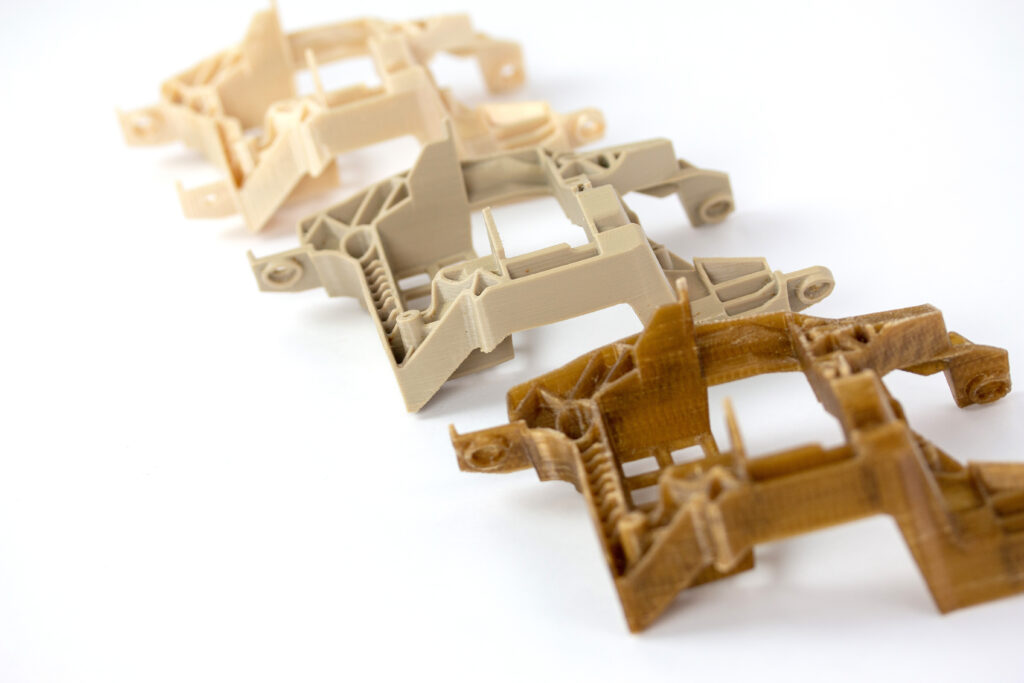

ULTEM™ printout printed by INDUSTRY F421

Reproducibility in 3D printing

Repeatability in 3D printing

Reproducibility, on the other hand, refers to the ability to produce the same result using different systems or processes. For example, if a part produced using one 3D printer can be successfully reproduced using a different 3D printer, the process could be considered reproducible. In one application, to restore the automotive production at an assembly line overseas, a team of engineers from Germany developed a part on their 3D printer, and immediately transferred its production to a plant in Mexico.

In general, repeatability is important for producing parts with consistent quality, while reproducibility is important for demonstrating that a particular process or design is robust and can be used by different manufacturers or research groups.

Obviously, both are very important for industrial 3D printers. When engaging in small-series production it is important to have confidence in quality of parts sequentially produced on one machine. And, with the growth of print farms and advent of global print fleets, the manufacturers need to know that a part developed in Germany would be produced with similar features in Mexico, Morocco or Thailand – wherever the 3D printer is located – with full process traceability when integrated with connected software such as the 3DGENCE Connect™ suite.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.