The food, pharmaceutical, steel, steel, and above all automotive industries could not function today without appropriate control systems. Thanks to well-designed and tailored tools this process can be automated, for example, machining errors can be detected on time and corrected, preventing the costly production of defective products. This is easier thanks to advanced vision systems. Manufacturers providing industrial automation solutions more and more often take advantage of the 3D printing technology.

High labour costs and the idea of industry 4.0, closely related to the progressive digitization of production processes, mean that companies are increasingly moving away from human control, focusing on full automation and robotics in this area. Vision systems that accurately identify and verify product positions, read barcodes, and detect damaged or incomplete batches on the line, have become an invaluable support for such organized manufacturing control.

Vision systems in many, but not all aspects, perform better than humans – they are resistant to fatigue, which leads to the loss of attention, which is so valuable in this case. They are perfect for the food or automotive industry – for example, when identifying parts delivered on assembly lines for various vehicle models.

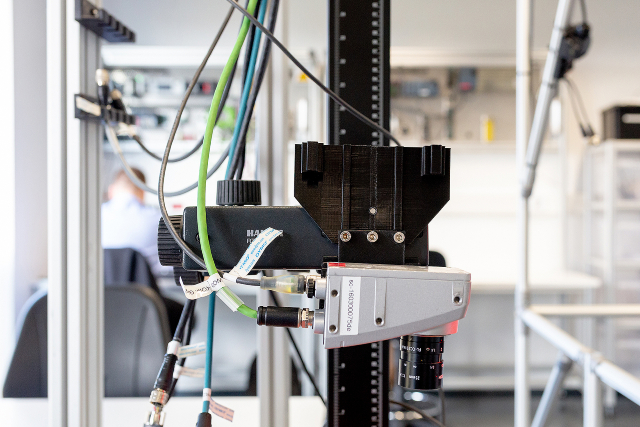

However, for industrial image processing systems (sensors and cameras with integrated software) to match human skills and perceptiveness, their suppliers are constantly working on more and more advanced methods and improvements. For example, Balluff enables the supplied vision systems to be tested under strictly defined environmental conditions. The main goal is to be able to adopt the industrial conditions of the customers in a special test laboratory.

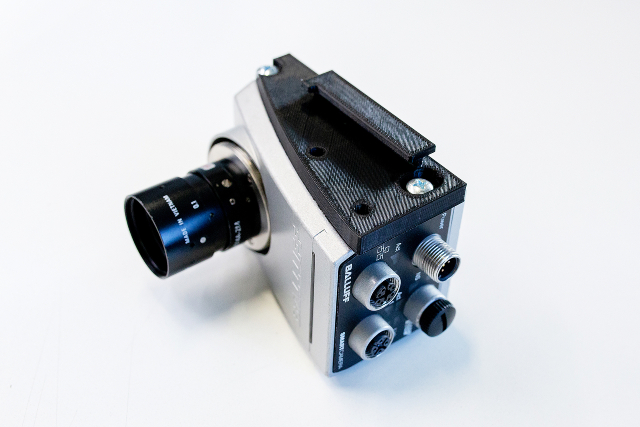

One of the key elements of the tested vision system is the proper installation of CCTV cameras. Their correct positioning is critical for the entire process, which is why it requires the use of custom mounting brackets matching the dimensions of the cameras.

Order a 3D printed sample

The cameras used in vision applications differ from each other in terms of technical parameters, electronics and, above all, geometry, which is why their mounting brackets must be very well matched. The best and cheapest way to customization is the 3D printing technology.

The use of 3D printing technology also allows you to significantly reduce the cost of production of parts that are used in the assembly of vision systems. Elements created on site in the company from materials such as ABS are cheaper than those ordered from external suppliers or made of aluminium.

The use of 3D printing technology also allows you to significantly reduce the cost of production of parts that are used in the assembly of vision systems. Elements created on site in the company from materials such as ABS are cheaper than those ordered from external suppliers or made of aluminium.

Companies that are courageous enough to invest in an advanced 3D printer will quickly notice the advantages and real profits of the fact that they can have full control over the geometry of the printed elements. If such a project is outsourced, only because of a bad fit you may lose a few days just to make the necessary adjustments and, of course, pay additional costs to boot.

Good and accurate equipment for industrial image processing ensures maximum quality and flexibility in the production process, which is why it is so important that its suppliers can properly match all the elements to the individual business and environmental needs of customers.

Taking advantage of the opportunities afforded by 3D printing allows us to meet such expectations, guaranteeing customers the stability and repeatability of vision during visual quality control, and suppliers can enjoy reduced costs, increased flexibility and thus be more competitive on the market.

Industrial 3D printer can be a complementary machine that supports traditional manufacturing processes. Choosing a proper machine that will suit your needs is not an easy task.

If you would like to know more what industrial 3D printer will be proper for your company, you can consult with 3D printing experts: [email protected]