Case study

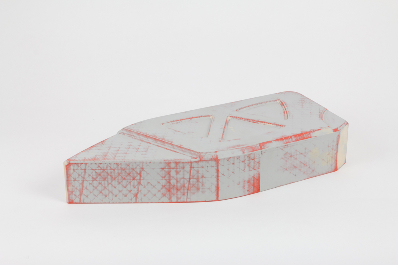

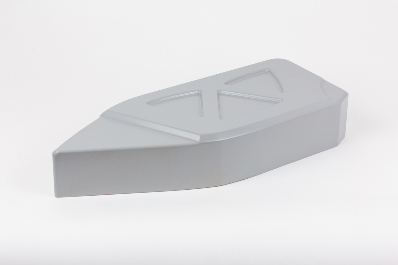

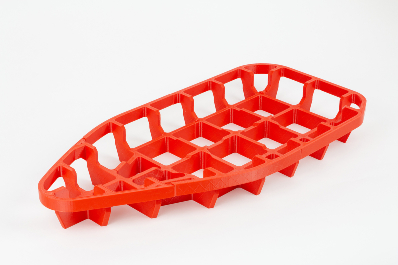

Making a 3D model for a final casting mould for the body of a cover for an electric bike battery.

The use of the industrial 3D printer in the performance of project considerably accelerated work on the construction of an electric bike.

Only several days were needed to print such a large model (540 x 220 x 100 mm)

3D printing enables creation of complex geometry structures without increasing the costs of manufacturing – only few design limitations. The use of 3DGence INDUSTRY F340 enabled unit production, in the situation of lack of access to CNC machines.

The application of 3D printers enabled the creation of a positive mould in a shorter time compared with the conventional technologies. 3D printing enabled fast progress through the subsequent design iterations. The final version of the positive was made in only 3 days, which shortened the time from design to ready product by 27 days.

In material removal processes material is removed by machining, grinding or drilling, which results in high material losses. A 3D printout was made of ABS, thanks to which the quantity of material used was minimised. The costs of the positive mould production were reduced by 92%.