CASE STUDY

Preoperative planning

Case study

PrintMed 3D is a company that designs and prepares 3D models that are used for medical purposes to preoperative planning.

3D printing is increasingly used in medicine and allows for detailed planning of operations. This makes it possible to select the appropriate operating technique, discuss it in the team, and shorten the time of the procedure itself.

Only the FDM technology gives the possibility to produce the anatomical models with a limited budget and in a short timeframe.

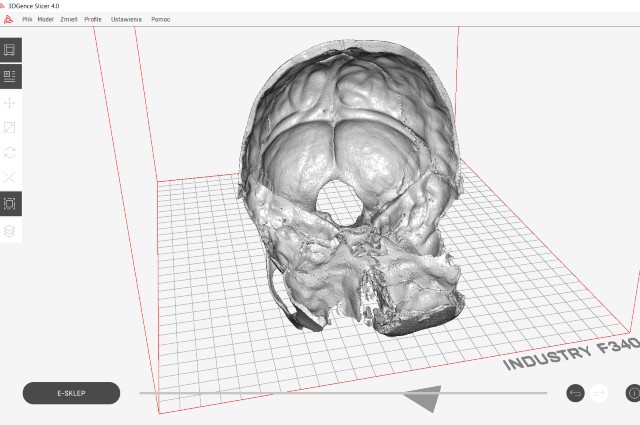

Design and print of the anatomical model of the child’s skull with the hydrocephalus – preparation for the implant placement surgery.

Pre-operative anatomical models allow to shorten the time of the operation and give the possibility of precise planning of the implantation. Lack of the model would increase the complications risk or other unexpected situations. The use of the 3DGence INDUSTRY F340 enabled the doctors to prepare for the operation very well. They could plan the various stages of the surgery before it was performed.

The model preparation would be hardly achievable in any other technology than 3D printing. Medical 3D imaging, design, injection molding could take up to two weeks and cost would be out of the reach of the clinic. The cost of the design and 3D printing of a highly complex model of skull was only 710 £ and the process took 30 hours.

Get the 3D printed parts you need just in time

The uncertainty of the child’s parents regarding the surgery course could’ve negatively influenced their decision of surgery attempt. Postponing the operation may have had a negative impact on the child’s health. Thanks to the 3D partial model of the skull the doctors have explained in detail the scope of the surgery, and easily received the parents’ consent for the surgery.

There may be a lot of crisis situations in the future that we can’t control. 3D printing can help you with many different applications through many materials. If you have not idea what filaments will proper for your project, you can consult it with our experts: [email protected]

Get in touch with 3D printing experts