3DGence ABS can be printed with ESM-10, soluble support material. This combination allows printing complex geometries, functional prototypes and many more.

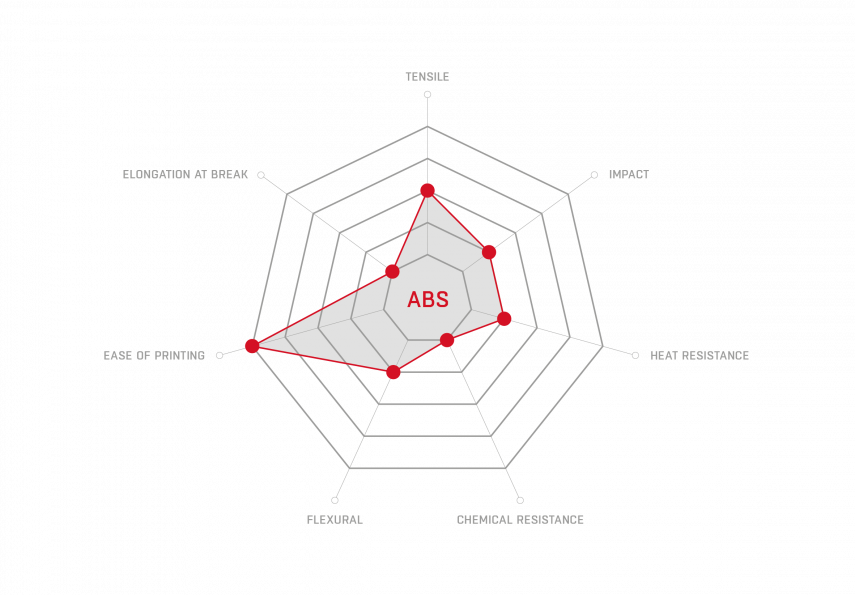

It is always easy to process and it has good mechanical properties to price ratio. ABS is a machinable material – it is possible to make the technological holes and even threads on the printed model. Relatively high hardness of the material results in high scratch resistance.

ABS shows some basic chemical resistance for acids, alkalis, and alcohols. It can be used in the applications that work in the temperature range of -20 – 80C. ABS is a recyclable material. The surface of the model made of ABS will be matte and the colours would be slightly less saturated than PLA made models.

ABS is not UV resistant, it should not be directly exposed to sunlight.

Low volume production

Additive manufacturing is frequently more cost-effective than other legacy manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time tp market.

End Use Parts

In many instances the mechanical properties and surface characteristics of 3D printed parts meet and exceed the customer’s expectation, allowing their use in the actual product.

Prior to launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components, accelerating the iterative development cycle and time to market.

We will help you to choose the right material