Polyamide (PA, Nylon)

Polyamide is one of the most used materials in the industry. It comes with many grades and can be filled with various fibers, spheres or nanotubes.

Polyamide is one of the most used materials in the industry. It comes with many grades and can be filled with various fibers, spheres or nanotubes.

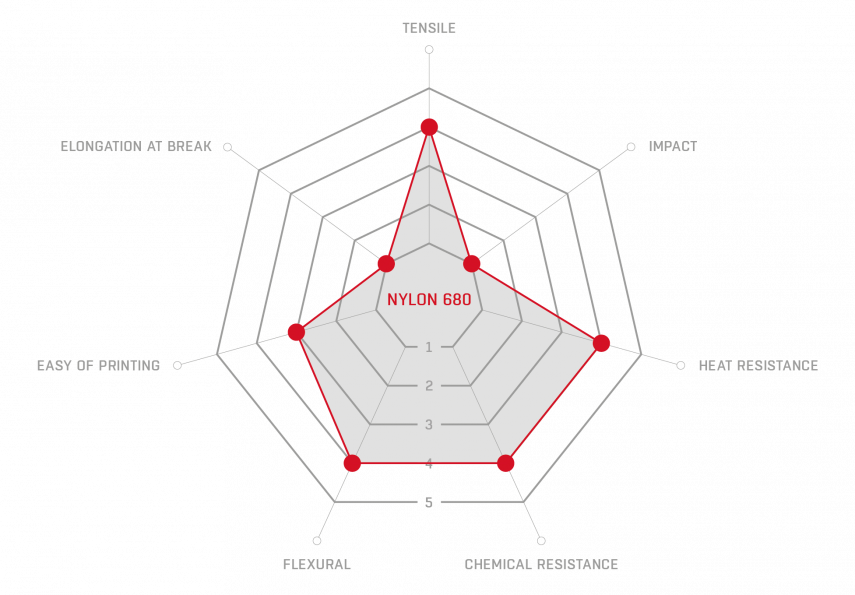

Nylon main feature is a very high tensile strength. The material is strong and has good tribological properties. On the other hand, it assures good elasticity and low moisture sensitivity of the printed models. Most common grade of the filament is PA6.

PA Neat is dedicated to industrial applications. The material is strong and has good tribological properties and on the other hand, it assures good elasticity and low moisture sensitivity of the printed models.

PA Neat provides continuous use at 120°C, maintaining sufficient mechanical properties and high-temperature resistance. It is a perfect material for producing durable prints that need to perform.

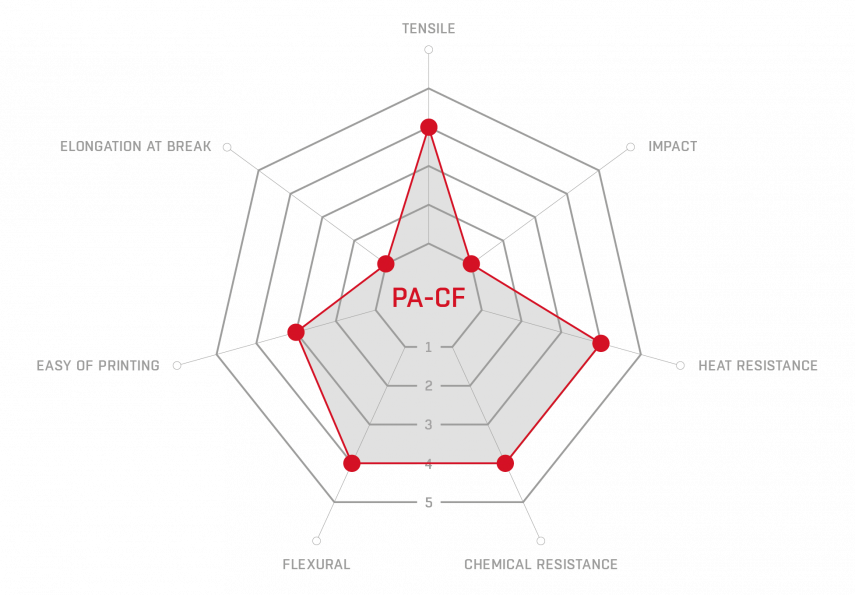

This industrial material is highly chemically and heat resistant. Comparing to standard PA material, the carbon-filled nylon is less susceptible to thermal shrinkage. It’s easier to control the material during the print process.

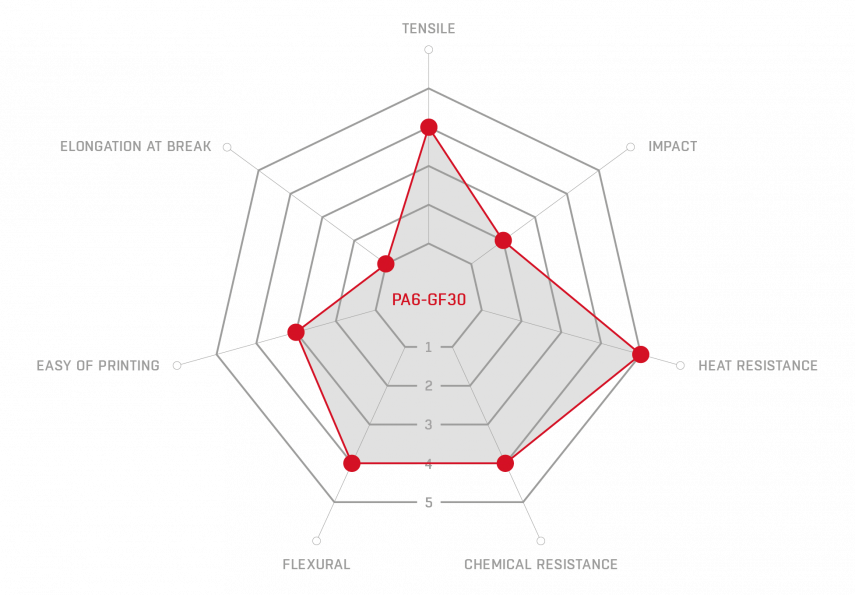

PA6-GF30 is a polyamide 6 copolymer, reinforced with 30% of glass fiber. The material shows exceptional stiffness and strength, but at the same time, the brittleness is very low. It has an excellent mechanical, chemical and thermal resistance that makes it suitable for a range of engineering and industrial applications. This grade of PA6 material can be easily used in the automotive industry as it shows particular resistance for fuels, lubricants, heat and high mechanical loads. Depending on the mechanical load it can withstand temperatures even up to 150°C. Dynamical load and creep resistance are also relatively high. Glass fiber reinforced polyamides have the ability to damp the vibrations. Due to high abrasive properties and friction coefficient, PA-GF materials are not suitable for the applications that include slipping and sliding.

PA6-GF30 also features improved dimensional stability – glass fibers reduce shrinkage, lift, and warp. The lamination of the layers is very strong.

PA6-GF30 is highly abrasive, please make sure you use the correct consumables and parts in the extruder.

The material is approved for contact with food. It is necessary to follow the rules of the Nylon filament storage since the material is highly hygroscopic.

Controlled humidity for loaded materials – regardless of the printers operational status. Most of the engineering and high-performance polymers have to be dried before use. 3DGence INDUSTRY F340 will do it for you. The materials are always pre-warmed and dry. peek

Controlled humidity for loaded materials – regardless of the printers operational status. Most of the engineering and high-performance polymers have to be dried before use. 3DGence INDUSTRY F340 will do it for you. The materials are always pre-warmed and dry.

We will help you to choose the right material

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.