Automate the correct preparation of your materials for accurate, strong, and high-quality parts. The MMS enables connected productivity, repeatability and full traceability of the printing process.

Material Management System (MMS)

3DGence MMS automates material storage, preparation, and post-print annealing – making successful printing of Ultra-Polymers like PEEK, ULTEM™, and Composites accurate and simplified.

As the shift from prototyping to end-use parts has become a reality through industrial grade 3D printers and advanced materials, automation and pre-configuration ensures print success.

Improper handling and preparation of materials can result in moisture creep, print failures, warping, and low visual quality – resulting in inaccurate parts and significantly reduced productivity.

Ensure print productivity, part integrity, and the highest quality with our Material Management System.

Parts printed from materials that are not stored properly have lower mechanical properties and visual quality.

MMS pre-programmed preparation modes ensure durable and accurate prints without visual defects.

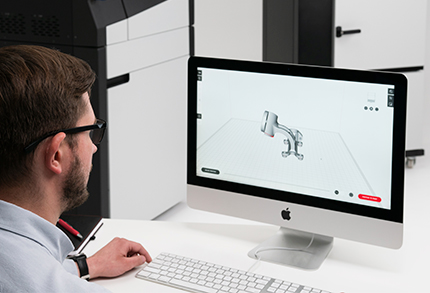

3DGence CONNECT is an evolving, fully interconnected system bringing together software, hardware, materials, and process control.

3DGence provides system control and traceability over the entire print process – from material to part.

Scan the material to the MMS to register the material into your print process and get full material traceability Proper Material Management is vital to part quality and integrity.

We make it easy and keep it connected.

Our Application Engineers are on standby to explain the technical details of the 3DGence connected system.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.