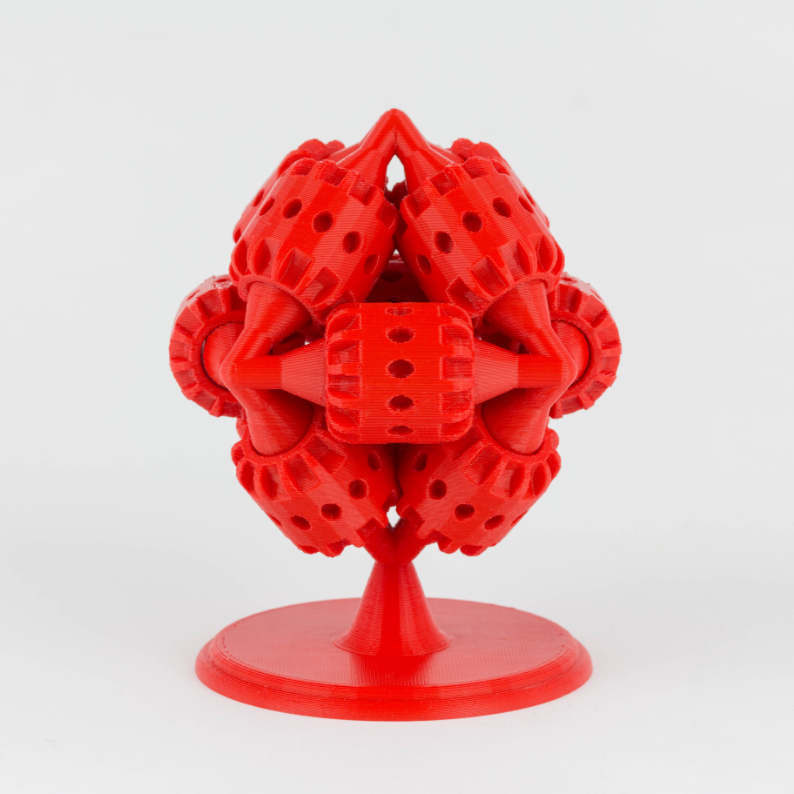

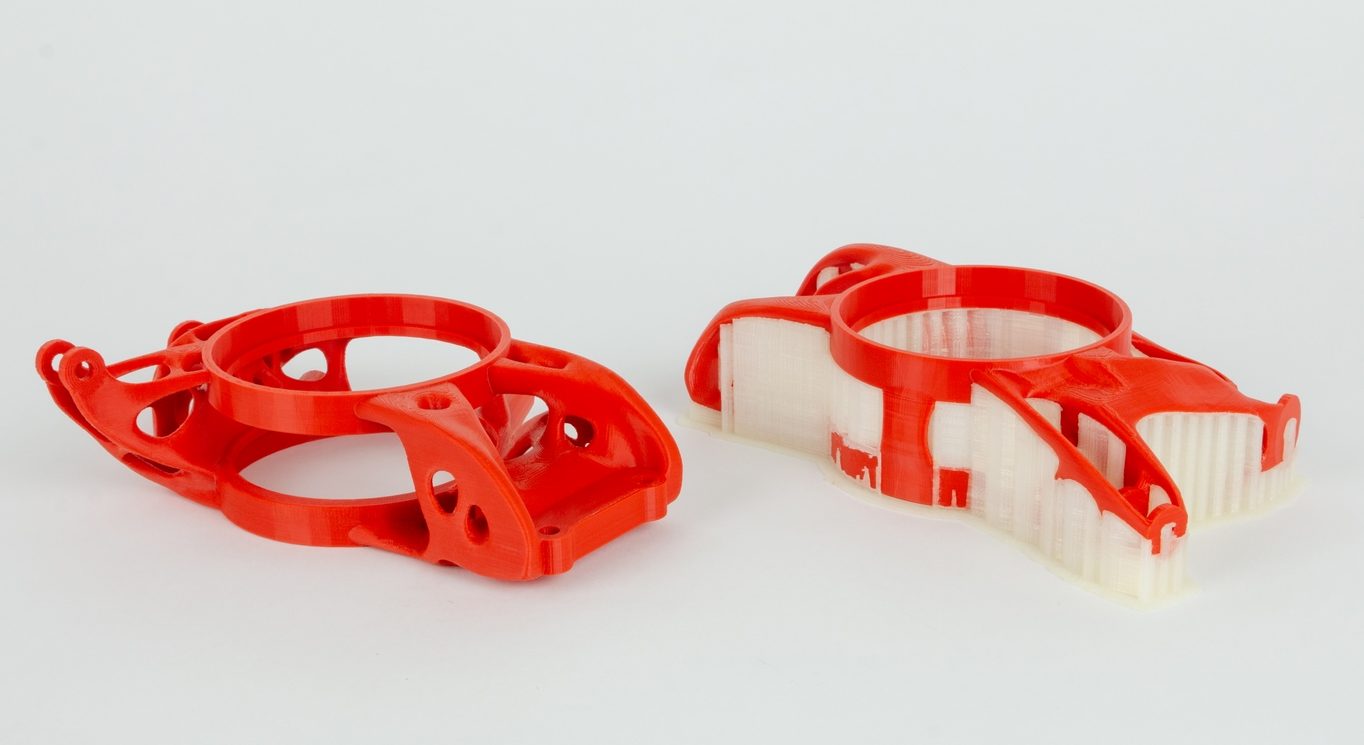

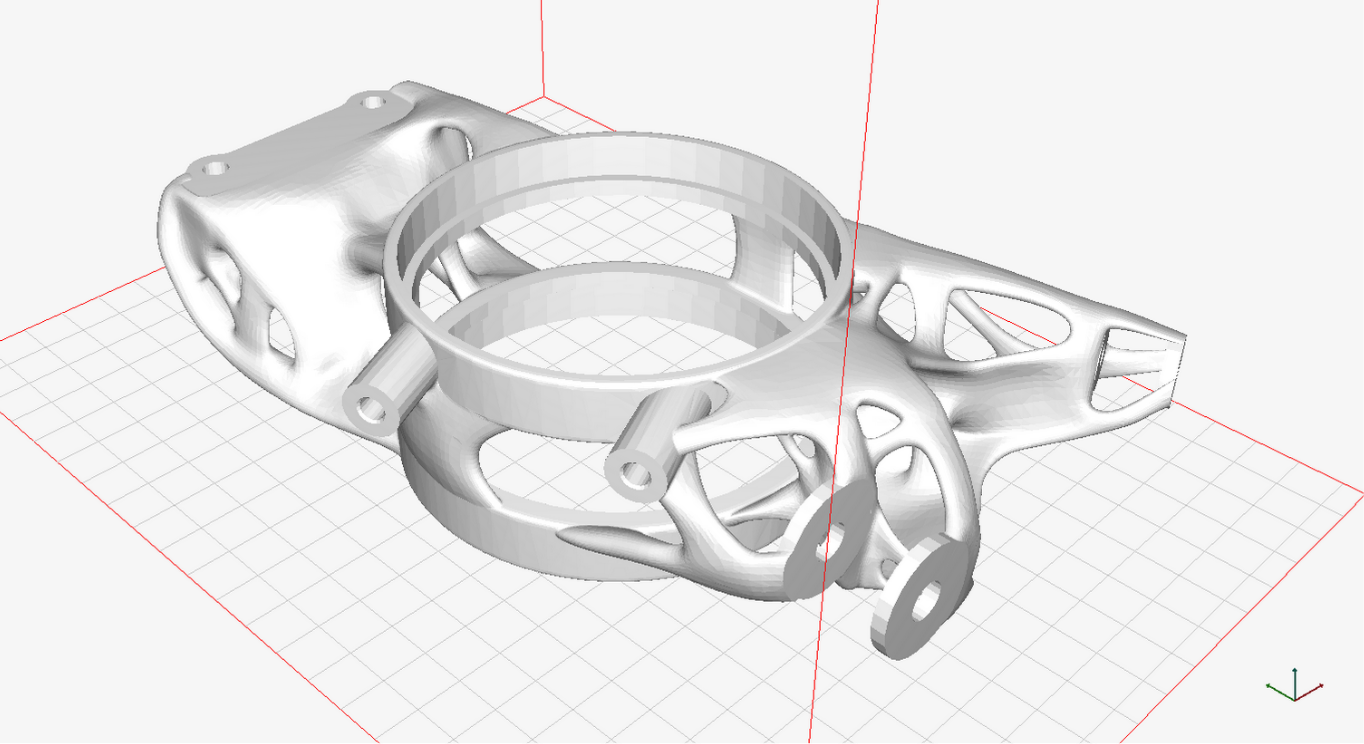

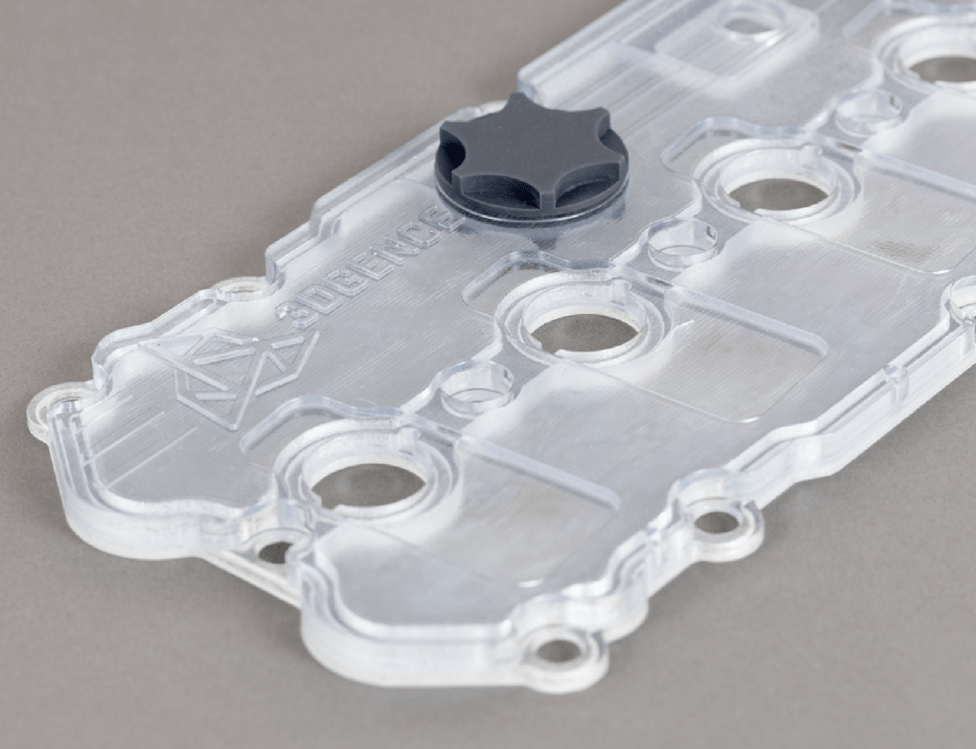

"The 3DGence company was of great help to MVRDV when our in house 3D printers were not able to perform our desired functions. 3DGence offered us proffessional consultations, by not only choosing the correct metod for our model, but also provided advice on how to improve our own models in the future. 3DGence provided us with two very precisely made models on time, a request other printing companies could not cope with. The whole cooperation process was very smooth and professional, which was appreciated by the whole team."

Sven Thorissen, Director/Architect, MVRDV