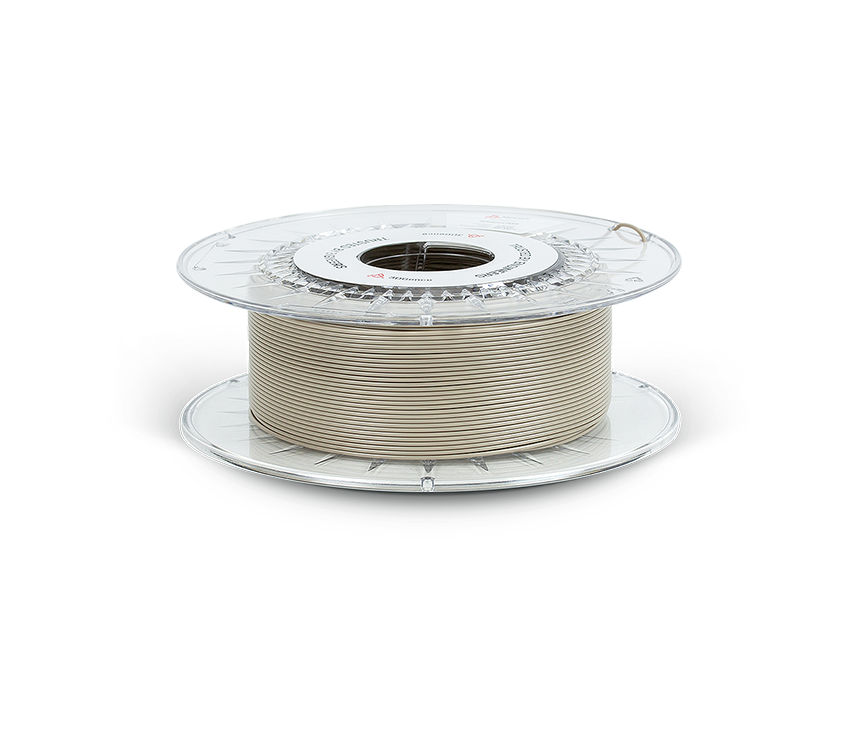

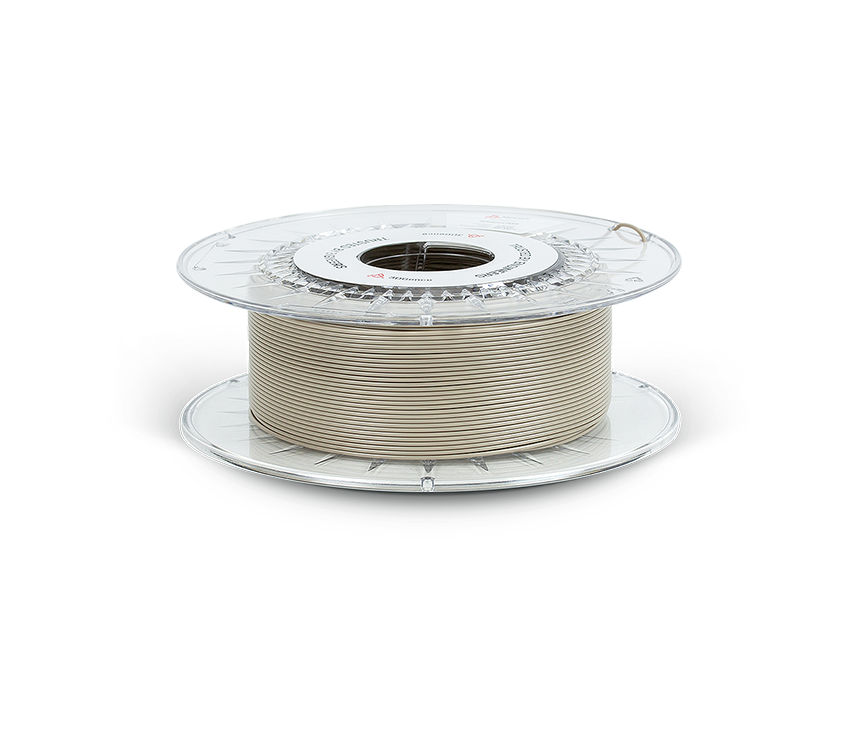

PEEK

PEEK is a high performance polymer from PAEK family which offers a unique combination of properties.

PEEK is a high performance polymer from PAEK family which offers a unique combination of properties.

PEEK typical applications include elements of machines and devices in automotive, marine, nuclear, oil-well, electronics, medical, and aerospace industries. Parts from this material are often chosen as metal parts replacement.

Usually the desirable state of PEEK is the semi-crystalline, which can be achieved after the annealing process of the printed model. In order to reach high dimensional accuracy of the models and the expected prints quality, the material needs high extrusion temperature, heated bed and the actively heated print chamber.

The highest-performing polymer with inherent UL94 V-0 flammability resistance, exceptional wear-, fatigue- and chemical resistance, now available with AS9100 aerospace certification.

AS9100 Aerospace Sector Quality System is based on well known ISO 9001 standard and tailor-made according to commercial and military aerospace regulations. AS9100 certification for 3DGence PEEK Aero gives you confidence that the quality management standard in our production facility is designed specifically to fulfill strict segment-specific requirements.

Highest-performing PAEK family polymer for easy printing of most durable end-use parts.

The new VICTREX PAEK filament has been developed to support a variety of demanding applications because of its very high wear resistance, high-temperature resistance, fatigue resistance and corrosion resistance to fluid/chemical, which when combined have the potential to increase design freedom and production cost efficiency.

The material VICTREX AM™ 200 has been specifically developed for use in additive manufacturing, with the approach to redesigning the polymer at a molecular level, achieving better prints without using additives and plasticisers. High crystallinity after annealing is achievable with VICTREX AM™ 200, contributing to chemical resistance and other properties.

3D printed PEEK models combine resistance to various chemicals, wear and fatigue. The material has exceptionally high-temperature resistance as well as very good mechanical properties. As a result, it is a perfect material for Oil&Gas, Aerospace and Automotive industries.

Our PEEK printers INDUSTRY F340 and INDUSTRY F420 offer printing with soluble support ESM-10. This solution gives more design freedom and helps reduce costs and post-processing time.

PEEK-CF filament incorporates 10% carbon fiber reinforcement for increased strength. Chopped carbon fiber gives the printed parts high stiffness and dimensional stability. This material provides long-term performance up to 240 °C, including exceptional chemical resistance. These properties make it particularly suited for metal replacement in critical applications in severe end-use environments, such as Oil & Gas, Aerospace and Automotive. The flammability of PEEK-CF is low, as well as the smoke and toxic gas emissions.

Thanks to high mechanical properties, PEEK-CF is being used for the responsible applications, allowing in some cases to even replace metal parts of the construction.

Low volume production

Additive manufacturing is frequently more cost-effective than other legacy manufacturing methods, allowing the rapid production of end-use parts at scale, reducing tooling and inventory costs and accelerating the time tp market.

End Use Parts

In many instances the mechanical properties and surface characteristics of 3D printed parts meet and exceed the customer’s expectation, allowing their use in the actual product.

Prior to launching mass production, engineering and designers benefit from 3D printing functional prototypes that can help verify fit, functionality and optimum integration with other components, accelerating the iterative development cycle and time to market.

We will help you to choose the right material