Case study

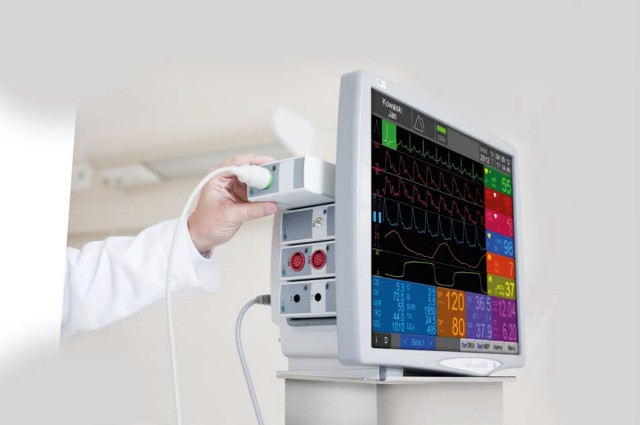

Emtel is a Polish supplier of medical equipment specialized in the production of patient monitor.

An optimal solution for entrepreneurs who want to avoid high costs and downtime at work and to easily prepare new versions of their devices may be the introduction of 3D printing. This technology allowed EMTEL to shorten the time needed by constructors and engineers to create and test products. Earlier, EMTEL commissioned patient monitor to be prepared for an external company, which raised costs and extended the duration of the entire process. Thanks to 3D printing, the company achieved a tenfold reduction in costs and shortening the production of housing.

Production of a new patient monitor model case prototype with the use of 3D printing technology to evaluate its ergonomics, dimensions, and accuracy.

The production cost of one patient monitor case made by external companies is about 500 EUR. Additionally, at the stage of forming the prototype, it is necessary to produce around 2 or 3 versions of the same model. EMTEL reduced production costs of models up to 90%. The cost of a single 3D print is around 50 EUR.

The production process of models and prototypes made by external enterprises takes minimum one month. Ownership of a 3D printer allows quickly make a designed model in 1:1 scale with satisfactory accuracy. The prototype of the patient monitor was received in 5 days which reduced expectation time up to 25 days.

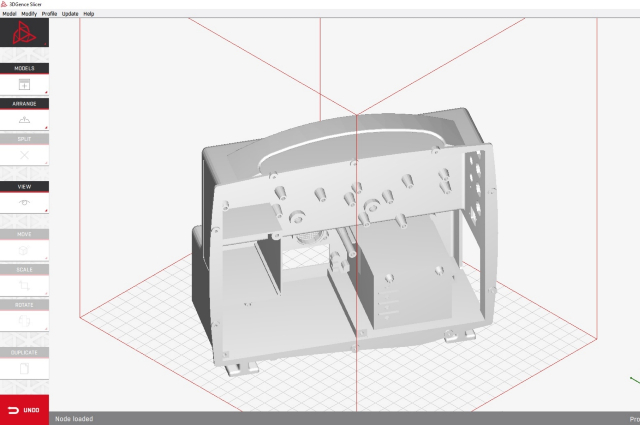

During the production of the case to patient monitor FX3000P, the expected precision was not worse than 0.2mm, especially in the mounting brackets. 3D printouts allowed to verify all critical dimensions of the project, it enabled to implement proper corrections.

Fast prototyping of new patient monitor model through precise verification of project assumptions, ergonomy, installation and validation of dimensions was only able due to the use of a 3D printer. The final details obtained with the use of injection technology did not require any corrections.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.