Industrial 3D printer: 9 key features

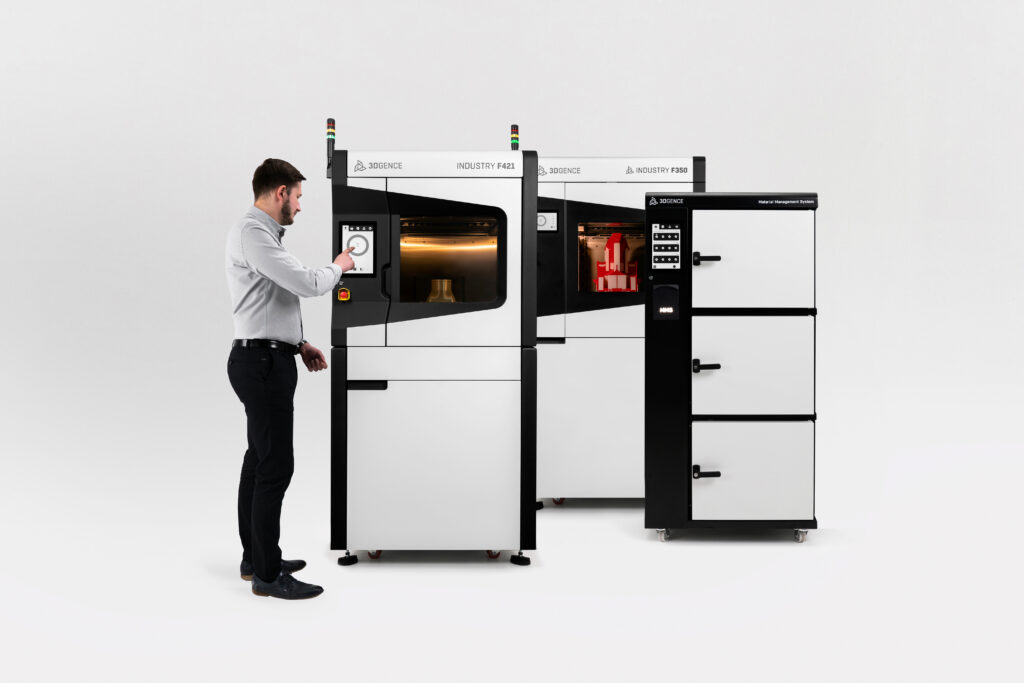

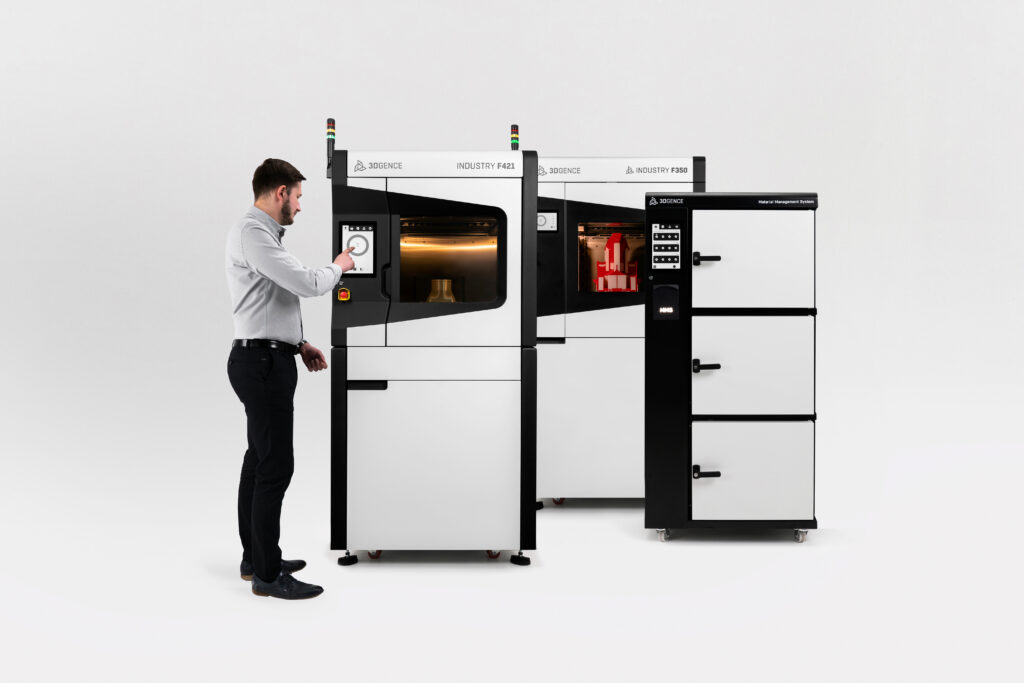

Industrial 3D printers FFF/FDM™ Key Differences: Industrial 3D printer vs. Desktop 3D printer. Many companies advertise their desktop 3D printers as “industrial”. Desktop printers may be

3D printing has never been more accessible than now. This technology has developed considerably over the years and can now perform pivotal role in many applications. More and more companies decide to implement 3D printing in order to optimize their business processes. Today, manufacturers enjoy the benefits of additive manufacturing on a daily basis, it is one of the most profitable solution in the production of spare parts for machines, production lines, tooling and prototypes.

Explore 3D printing applications in a variety of industries, discover inspiring succes stories, find the latest companies news and comprehensive white papers. This is the source of knowledge for all things related to 3D printing technoloy. Learn from 3DGence experience.

Industrial 3D printers FFF/FDM™ Key Differences: Industrial 3D printer vs. Desktop 3D printer. Many companies advertise their desktop 3D printers as “industrial”. Desktop printers may be

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.